Catalog excerpts

Link Engineering Company www.linkeng.com Booster Test Stand - Performance/NVH Model 3394 The Model 3394 Booster Test Stand is specifically configured to evaluate performance & NVH of a brake vacuum booster system . These tests are performed by applying linear actuation to the brake booster, simulating service conditions, and measuring displacement, stroke, pressure, load, and noise characteristics of the brake system. Booster actuation with stroke or force control, available through servo controlled air supply. A source vacuum is provided on the stand to recreate vacuum from engine. An array of spring disc test consumers at varying stiffness are used to simulate the reactant force from a brake caliper. Automatic evacuation and fill of brake fluid. Designed to comply with GMW 14934 & GMW 14590 test specifications. Full anechoic chamber with mountable brake actuation system provided for NVH testing. Microphones and Link designed software for noise level acquisition and analysis. The test control and data acquisition functions are performed by a PC based control system running ProLink Windows® Software. The openarchitecture software allows for customization to suit the user's testing needs. Automated or manual test parameters are easily configured to run required test procedures Stainless Steel Bench Spring Consumers with User-Defined Stiffness for Caliper Simulation Panel Mounted Gauges for High Visibility Linear Actuation for Force or Stroke Applications Panel Mounted Supply Connections Control Desk ProLink Control Software Optional Full Anechoic Chamber & Noise Acquisition System Designed to meet GMW procedures 14934 & 14590 For more information on the Model 3394 Booster Test Stand and how it can be configured to meet your test requirements, contact LINK at 734-453-0800 x3155 or sales@linkeng.com. Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America and Around the World Link Engineering Company 734-453-0800 Asia ● Europe ● North America ● South America

Open the catalog to page 1

Link Engineering Company www.linkeng.com Booster Test Stand Model 3394 Typical Specifications Fluid Displacement Transducer Type LINK Flow Meter Maximum Flow Volume Flow Resolution Minimum Flow Maximum Flow Pressure Measurement Primary Max Pressure Pressure Resolution Force / Stroke Apply Systems Maximum Stroke Stroke Resolution Stroke Speed Maximum Force Force Accuracy Force Ramp Rate Data Acquisition System Data Channels Sample Rate (per channel) Facility Requirements Electrical Supply Pneumatic Supply Disclaimer: Information presented in this brochure is for informational purposes only....

Open the catalog to page 2All Link Engineering catalogs and technical brochures

-

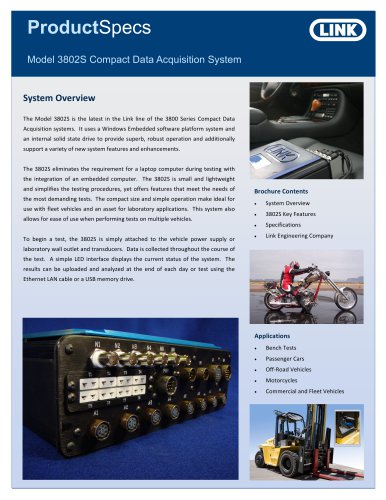

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages