Catalog excerpts

Features • ProLink Software • Automatic or manual control modes • Flexible testing configuration • Variable speed input • Variable system binding torque • Hard-geared system The Model 1800 Four Square Test System is designed to test durability of drive shafts, halfshafts and universal joints under typical and extreme operating conditions. The Model 1800 provides great flexibility and can be configured to accommodate your test needs. The machine is capable of testing four drive shafts and eight U-Joints simultaneously in a hard-geared loop. Once this loop is connected, the rotary torque generator can be actuated to rotate one end in respect to the other end, therefore creating binding torque without using a braking device. The Four Square machine can also accommodate two drive shafts and four U-Joints by removing the jounce section. This allows testing of extra long shafts up to 100” in length. This configuration allows constant and uniform torque throughout all four shafts at a selected speed even if the specimen’s physical dimensions change. This design facilitates the replication of actual operating conditions. Link Engineering Company www.linkeng.com Four Square Test System Model 1800 Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America and Around the World Asia œ Europe œ North America œ South America Link Engineering Company 734-453-0800 www. linkeng.com The Jounce section provides the ability to offset one end of the shaft with respect to the other end simulating suspension movement as it occurs during driving. The maximum offset is 13.75” (350 mm) or eight degrees angle to the shaft axis. The Jounce section may be set at certain offset for the duration of the test or it can be programmed to oscillate at a rate up to 0.5 Hz.

Open the catalog to page 1

Typical Specifications Number of shafts per test 2 or 4 Shaft length range 15” - 100” (400-2500mm) Maximum Shaft Diameter 6.3” (160mm) Number of U joints per test 4 or 8 Maximum Static Torque 177,000 in-lbs @ 0 RPM (20000 Nm) Maximum Dynamic Torque 177,000 in-lbs @ 500 RPM (20000Nm) Power 300 HP - AC Variable Speed Speed 0-6000 RPM Maximum Drive Shaft Angle or Movement 13.8” (350mm) Jounce Frequency 0.5 Hz Controls ProLink Software Maximum Tensile Load 33,720 lbs (150 kN) @ Max Torque Environmental Chamber (Optional) Water & Dust Spray System Temp. 5C – 40C Relative Humidity 20% - 80%...

Open the catalog to page 2All Link Engineering catalogs and technical brochures

-

friction testing machine

2 Pages

-

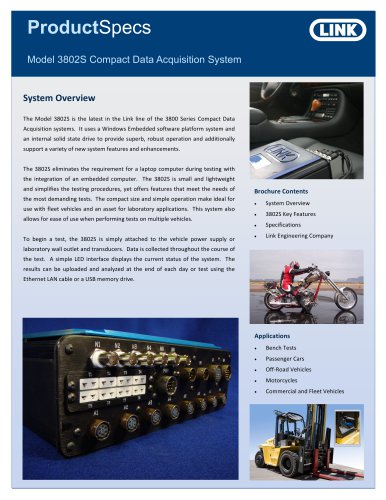

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages