Catalog excerpts

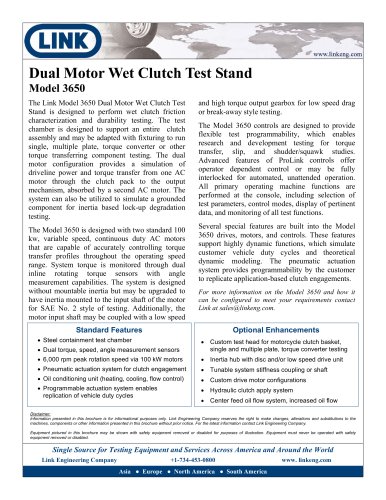

Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America and Around the World Asia œ Europe œ North America œ South America Link Engineering Company +1-734-453-0800 www. linkeng.com Dual Motor Wet Clutch Test Stand Model 3650 The Link Model 3650 Dual Motor Wet Clutch Test Stand is designed to perform wet clutch friction characterization and durability testing. The test chamber is designed to support an entire clutch assembly and may be adapted with fixturing to run single, multiple plate, torque converter or other torque transferring component testing. The dual motor configuration provides a simulation of driveline power and torque transfer from one AC motor through the clutch pack to the output mechanism, absorbed by a second AC motor. The system can also be utilized to simulate a grounded component for inertia based lock-up degradation testing. The Model 3650 is designed with two standard 100 kw, variable speed, continuous duty AC motors that are capable of accurately controlling torque transfer profiles throughout the operating speed range. System torque is monitored through dual inline rotating torque sensors with angle measurement capabilities. The system is designed without mountable inertia but may be upgraded to have inertia mounted to the input shaft of the motor for SAE No. 2 style of testing. Additionally, the motor input shaft may be coupled with a low speed and high torque output gearbox for low speed drag or break-away style testing. The Model 3650 controls are designed to provide flexible test programmability, which enables research and development testing for torque transfer, slip, and shudder/squawk studies. Advanced features of ProLink controls offer operator dependent control or may be fully interlocked for automated, unattended operation. All primary operating machine functions are performed at the console, including selection of test parameters, control modes, display of pertinent data, and monitoring of all test functions. Several special features are built into the Model 3650 drives, motors, and controls. These features support highly dynamic functions, which simulate customer vehicle duty cycles and theoretical dynamic modeling. The pneumatic actuation system provides programmability by the customer to replicate application-based clutch engagements. For more information on the Model 3650 and how it can be configured to meet your requirements contact Link at sales@linkeng.com. Standard Features • Steel containment test chamber • Dual torque, speed, angle measurement sensors • 6,000 rpm peak rotation speed via 100 kW motors • Pneumatic actuation system for clutch engagement • Oil conditioning unit (heating, cooling, flow control) • Programmable actuation system enables replication of vehicle duty cycles Optional Enhancements • Custom test head for motorcycle clutch basket, single and multiple plate, torque converter testing • Inertia hub with disc and/or low speed drive unit • Tunable system stiffness coupling or shaft • Custom drive motor configurations • Hydraulic clutch apply system • Center feed oil flow system, increased oil flow

Open the catalog to page 1

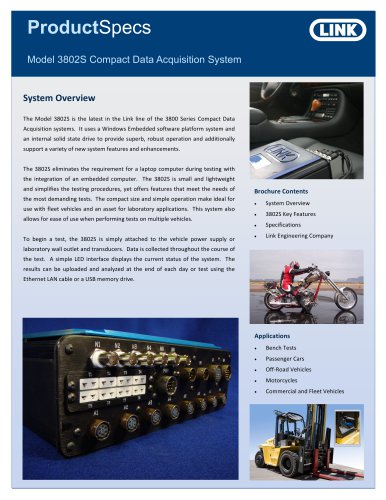

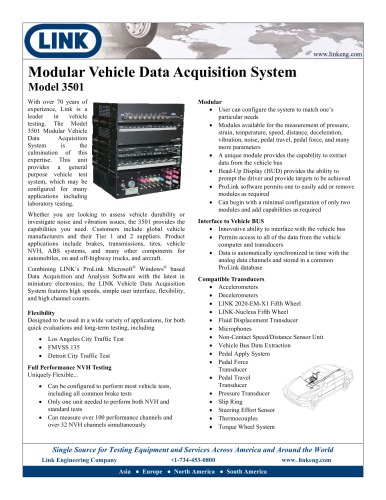

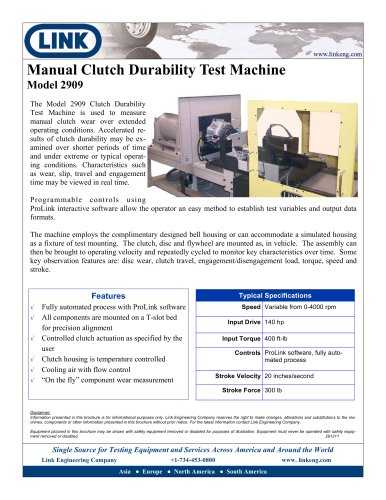

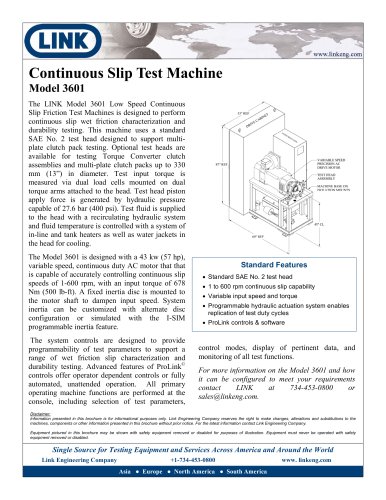

Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America...

Open the catalog to page 2All Link Engineering catalogs and technical brochures

-

friction testing machine

2 Pages

-

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages