Catalog excerpts

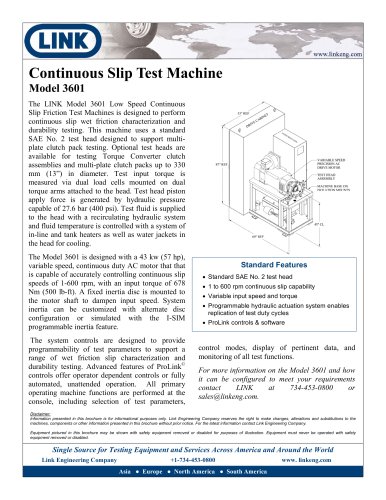

Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America and Around the World Asia œ Europe œ North America œ South America Link Engineering Company +1-734-453-0800 www. linkeng.com Continuous Slip Test Machine Model 3601 The LINK Model 3601 Low Speed Continuous Slip Friction Test Machines is designed to perform continuous slip wet friction characterization and durability testing. This machine uses a standard SAE No. 2 test head designed to support multiplate clutch pack testing. Optional test heads are available for testing Torque Converter clutch assemblies and multi-plate clutch packs up to 330 mm (13”) in diameter. Test input torque is measured via dual load cells mounted on dual torque arms attached to the head. Test head piston apply force is generated by hydraulic pressure capable of 27.6 bar (400 psi). Test fluid is supplied to the head with a recirculating hydraulic system and fluid temperature is controlled with a system of in-line and tank heaters as well as water jackets in the head for cooling. The Model 3601 is designed with a 43 kw (57 hp), variable speed, continuous duty AC motor that that is capable of accurately controlling continuous slip speeds of 1-600 rpm, with an input torque of 678 Nm (500 lb-ft). A fixed inertia disc is mounted to the motor shaft to dampen input speed. System inertia can be customized with alternate disc configuration or simulated with the I-SIM programmable inertia feature. The system controls are designed to provide programmability of test parameters to support a range of wet friction slip characterization and durability testing. Advanced features of ProLink© controls offer operator dependent controls or fully automated, unattended operation. All primary operating machine functions are performed at the console, including selection of test parameters, control modes, display of pertinent data, and monitoring of all test functions. For more information on the Model 3601 and how it can be configured to meet your requirements contact LINK at 734-453-0800 or sales@linkeng.com. Standard Features • Standard SAE No. 2 test head • 1 to 600 rpm continuous slip capability • Variable input speed and torque • Programmable hydraulic actuation system enables replication of test duty cycles • ProLink controls & software

Open the catalog to page 1

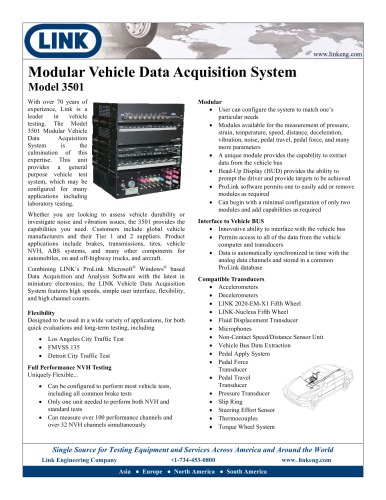

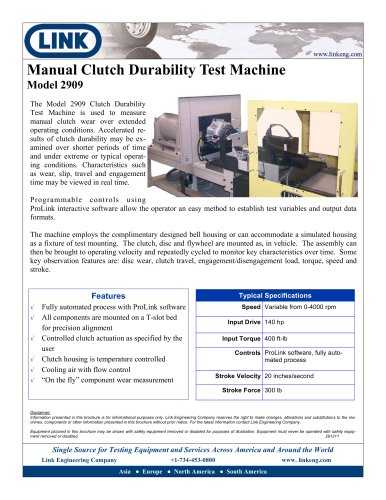

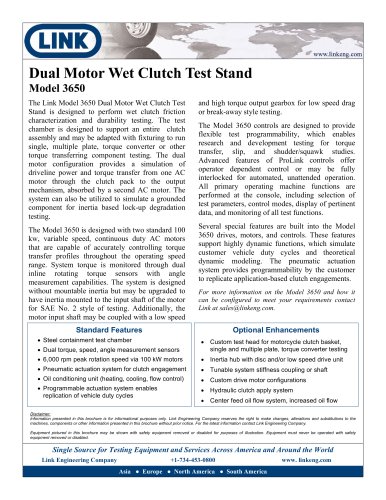

Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America...

Open the catalog to page 2All Link Engineering catalogs and technical brochures

-

friction testing machine

2 Pages

-

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages