Catalog excerpts

Link Engineering Company Link Engineering’s latest wheel test system goes beyond traditional methods, giving better results and saving time drum cannot handle more than 4-5 horsepower without destroying itself very rapidly. Lastly, biaxial fatigue testing is a method that loads the tire/wheel against the inside diameter of a drum (800-1,100mm) using a road load le from the vehicle or a duty cycle as per the SAE J2562 standard. Loads are developed in the tire/wheel assembly through a cambering mechanism that uses the tire-to-drum friction and the curb proles inside the drum to develop an overturning Actual damage with moment control/ microstrain x cycles/1m moment. Using electric actuators with fast response and high-speed drives, the total test duration on Link’s Model 3536 biaxial wheel test system is reduced by 50% compared with other test systems. Test speeds are typically 150-200km/h. Link’s newly developed Moment Method controls the overturning moment and the radial and lateral loads that the wheel is subjected to in actual use. Superior to controlling only the radial and lateral loads, real-time control of the overturning moment also compensates for tire tread temperature, wear, ination pressure and friction against the drum, which affects the actual stresses imposed on the test wheel. The graph below illustrates the correlation of the Moment Method with the total damage desired as measured by a strain gauge array. In summary, modern wheel testing uses biaxial load les to better reproduce customer usage. ‹ include cornering fatigue testing, which uses the rim mounted on a turntable with a radial load applied at a given distance from the wheel center. This load offset introduces a controlled overturning moment to the rim, which induces stresses in the disk of the wheel as if driving the vehicle in a tight circle. The test allows high loads and speeds as no tire is used. It is important to note that this test, using a xed load, can oversize the wheel compared with more realistic biaxial duty cycles. Alternatively, external drum fatigue is where a tire/ wheel assembly is loaded against a 1.7-2m drum in the radial direction, with steering to impose a lateral loading and generate an overturning moment. A disadvantage of this method is that the time to run a test is dened by the tire’s limited ability to handle all loads at a reasonable test speed. A car tire rolling on a ONLINE READER ENQUIRY NUMBER Efcient and effective laboratory evaluation of wheel durability is an ongoing requirement for the automotive industry. New methods that rely on six-axis wheel force transducers (WFT) and special control algorithms now enable test and application engineers to crunch the development time for a new wheel load le from weeks to days. Since new automotive wheel designs are a common part of vehicle design updates and new vehicle programs, having an efcient and repeatable test method is critical to keeping wheels safe and the product development cycle efcient. Link has worked diligently to develop new technologies for testing wheels. Recent development of biaxial methods replicating radial load, lateral load and the overturning moment have greatly increased precision and efciency for durability testing. The main laboratory wheel tests include impact tests and traditional fatigue tests such as cornering fatigue, external drum fatigue and biaxial fatigue. Impact tests are where the wheel and tire assembly is impacted with a standard striker to simulate impacts with a curb or from hitting a pothole in the road. This test is often used to inict a predetermined amount of damage before fatigue testing. The wide-ranging traditional fatigue evaluations Biaxial wheel durability testing ABOVE: Link says that its Moment Method can save wheel suppliers months of time and thousands of dollars LEFT: Correlation between Moment Method and total wheel damage desired Set point for total damage/microstrain x cycles/1m

Open the catalog to page 1All Link Engineering catalogs and technical brochures

-

friction testing machine

2 Pages

-

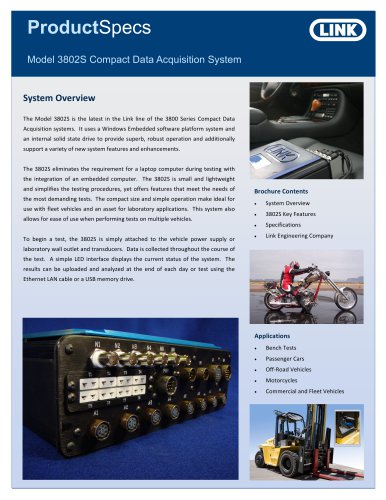

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages