Catalog excerpts

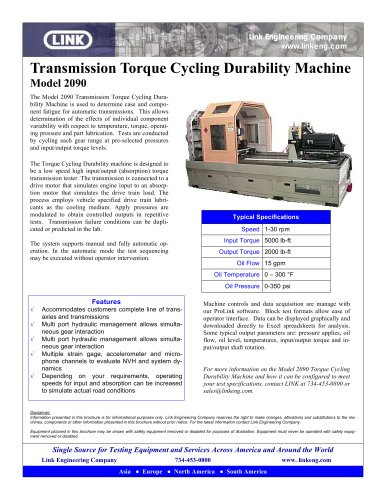

The Model 2090 Transmission Torque Cycling Durability Machine is used to determine case and component fatigue for automatic transmissions. This allows determination of the effects of individual component variability with respect to temperature, torque, operating pressure and part lubrication. Tests are conducted by cycling each gear range at pre-selected pressures and input/output torque levels. The Torque Cycling Durability machine is designed to be a low speed high input/output (absorption) torque transmission tester. The transmission is connected to a drive motor that simulates engine input to an absorption motor that simulates the drive train load. The process employs vehicle specified drive train lubricants as the cooling medium. Apply pressures are modulated to obtain controlled outputs in repetitive tests. Transmission failure conditions can be duplicated or predicted in the lab. The system supports manual and fully automatic operation. In the automatic mode the test sequencing may be executed without operator intervention. Features ã Accommodates customers complete line of transaxles and transmissions ã Multi port hydraulic management allows simultaneous gear interaction ã Multi port hydraulic management allows simultaneous gear interaction ã Multiple strain gage, accelerometer and microphone channels to evaluate NVH and system dynamics ã Depending on your requirements, operating speeds for input and absorption can be increased to simulate actual road conditions Typical Specifications Speed 1-30 rpm Input Torque 5000 lb-ft Output Torque 2000 lb-ft Oil Flow 15 gpm Oil Temperature 0 – 300 °F Oil Pressure 0-350 psi Link Engineering Company www.linkeng.com Transmission Torque Cycling Durability Machine Model 2090 Disclaimer: Information presented in this brochure is for informational purposes only. Link Engineering Company reserves the right to make changes, alterations and substitutions to the machines, components or other information presented in this brochure without prior notice. For the latest information contact Link Engineering Company. Equipment pictured in this brochure may be shown with safety equipment removed or disabled for purposes of illustration. Equipment must never be operated with safety equipment removed or disabled. Single Source for Testing Equipment and Services Across America and Around the World Asia œ Europe œ North America œ South America Link Engineering Company 734-453-0800 www. linkeng.com Machine controls and data acquisition are manage with our ProLink software. Block test formats allow ease of operator interface. Data can be displayed graphically and downloaded directly to Excel spreadsheets for analysis. Some typical output parameters are: pressure applies, oil flow, oil level, temperatures, input/output torque and input/ output shaft rotation. For more information on the Model 2090 Torque Cycling Durability Machine and how it can be configured to meet your test specifications, contact LINK at 734-453-0800 or sales@linkeng.com.

Open the catalog to page 1All Link Engineering catalogs and technical brochures

-

friction testing machine

2 Pages

-

3802S

4 Pages

-

Wet Friction Clutch Testing

4 Pages

-

Clutch Burst Machine

2 Pages

-

FAST Dry Friction Test Stand

2 Pages