Catalog excerpts

Screw jacks with travelling ball nut (Mod.B) 3.1 MA Series Mod.B - STRUCTURAL ELEMENTS 1 10 14 1 - ball screw in quenched and tempered alloy steel 2 - ball nut in case-hardened steel with flange according to DIN 69051 (available also with cylindrical flange), with grease nipple and end seals 3 - worm with ground ZI involute thread profile (UNI 4760) in case-hardened steel 4 - bronze worm wheel with true involute profile ZI (UNI 4760) 5 - cast iron support of the bronze worm wheel rim (size 5 and 10: entire wormwheel in bronze) 6 - ball screw fixed to the worm wheel through the cylindrical centring part and metric thread LEFT-HAND for PUSH load or RIGHT-HAND for PULL load 7 - lock nut with opposite metric thread direction to ensure a safe ball screw fixing 8 - ball screw – wormwheel pins against unscrewing 9 - thrust ball bearing for high load capacity 10- gear box 11 - low cover 12 - raised cover; may also be used as a centring diameter 13 - wormwheel radial bronze guide for higher stiffness and better efficiency 14 - grub screw to prevent the threaded cover unscrewing 15 - long-life synthetic oil lubricated worm gearbox 16 - radial lubricant seal 17 - O-ring 18 - breather 19 - oil level plug 20 - oil drain plug

Open the catalog to page 1

Screw jacks with travelling ball nut (Mod.B) 3.2 SJ Series Mod.B - STRUCTURAL ELEMENTS 1 1 - ball screw in quenched and tempered alloy steel 2 - ball nut in case-hardened steel with flange according to DIN 69051 (available also with cylindrical flange), with grease nipple and end seals 3 - worm with ground ZI involute thread profile (UNI 4760) in case-hardened steel 4 - bronze worm wheel with true involute profile ZI (UNI 4760) 5 - cast iron support of the bronze worm wheel rim (size 5 ... 100: entire wormwheel in bronze) 6 - ball screw fixed to the worm wheel through the cylindrical...

Open the catalog to page 2

Screw jacks with travelling ball nut (Mod.B) 3.3 HS Series - STRUCTURAL ELEMENTS 1 1 - ball screw in quenched and tempered alloy steel 2 - ball nut in case-hardened steel with flange according to DIN 69051 (available also with cylindrical flange), with grease nipple and end seals 3 - solid input shaft with key (or flange and hollow shaft for motor coupling) 4 - bevel gear in case-hardened and tempered steel 5 - output hollow shaft in hardened and tempered steel 6 - key to transmit the torque to the output shaft 7 - key to transmit the torque to the output shaft 8 - thrust ball bearing for...

Open the catalog to page 3

Screw jacks with travelling ball nut (Mod.B) 3.4 Standard ball screw – gearbox arrangements Diameter Lead It is possible to supply screw-gearbox arrangements different from the standard ones. For more information please contact SERVOMECH. 3.5 Max. input power Pmax Following tables show the MAX. INPUT POWER Pmax [kW] to the gearbox at different speeds, calculated for a gear life of 10 000 hours. For different life requirements, please contact SERVOMECH. MA n1 [rpm] 3 000 1 500 1 000 750 500 300 100

Open the catalog to page 4

Screw jacks with travelling ball nut (Mod.B) 3.6 TECHNICAL DATA MA BS Series Mod.B Load capacity [kN], (push - pull) Worm gear centre distance Mass of gear box without ball screw casting in aluminium alloy EN 1706 - AC-AlSi10Mg T6 casting in spheroidal graphite iron EN-GJS-500-7 (UNI EN 1563) Load capacity [kN], (push - pull) [mm] high Mass of gear box without ball screw casting in aluminium alloy EN 1706 - AC-AlSi10Mg T6 Worm gear centre distance casting in grey cast iron EN-GJL-250 (UNI EN 1561) 10.4 Load capacity [kN], (push - pull) Housing side dimensions casting in grey cast iron...

Open the catalog to page 5

Screw jacks with travelling ball nut (Mod.B) 3.6 TECHNICAL DATA MA 80 BS Load capacity [kN], (push - pull) Worm gear centre distance casting in spheroidal graphite iron EN-GJS-500-7 (UNI EN 1563) 26 Mass of gear box without ball screw casting in grey cast iron EN-GJL-250 (UNI EN 1561) 55 Load capacity [kN], (push - pull) Worm gear centre distance welded steel Gear box material S355 J2 (UNI EN 10025) 120 Mass of gear box without ball screw Load capacity [kN], (push - pull) Housing side dimensions casting in grey cast iron EN-GJL-250 (UNI EN 1561) 38 Mass of gear box without ball screw

Open the catalog to page 6

Screw jacks with travelling ball nut (Mod.B) 3.7 Ball screws and nuts technical data Ball screws produced with whirling process, accuracy grade IT 5 (1) Ball screw (1) - ball screws with accuracy grade IT 3 can be supplied on request (2) - the nut code in the table is incomplete; to complete it refer to Ch. 3.8 “B

Open the catalog to page 7

Screw jacks with travelling ball nut (Mod.B) 3.7 Ball screws and nuts technical data Rolled ball screws, accuracy grade IT 7 Ball screw (2) - the nut code in the table is incomplete; to complete it refer to Ch. 3.8 “Ball nu

Open the catalog to page 8

Screw jacks with travelling ball nut (Mod.B) 3.8 Ball nut dimensions Nuts with flange according to DIN 69051 Ball screw Flange type

Open the catalog to page 9

Screw jacks with travelling ball nut (Mod.B) 3.8 Ball nut dimensions Nuts with flange at SERVOMECH drawing SERVOMECH Ball screw Flange type Flange type: 2 8 holes at 45° (d0 ≥ 40 mm) Flange type: 1 6 holes at 60° (d0 < 40 mm)

Open the catalog to page 10

Screw jacks with travelling ball nut (Mod.B) 3.9 Ball nut life Ball screw diameter 16 - 20, accuracy grade IT 3 or IT 5 Following life diagrams refer to a constant applied load, without shocks and 90 % ball screw reliability. For different load and/or reliability conditions, please refer to ch. 1.11 “Ball screw life calculation” on page 18 or contact SERVOMECH. 10 9 8 7 6 5 4 Life in performed stroke [km]

Open the catalog to page 11

Screw jacks with travelling ball nut (Mod.B) 3.9 Ball nut life Ball screw diameter 16 - 20, accuracy grade IT 7 Following life diagrams refer to a constant applied load, without shocks and 90 % ball screw reliability. For different load and/or reliability conditions, please refer to ch. 1.11 “Ball screw life calculation” on page 18 or contact SERVOMECH. 10 9 8 7 6 5 4 Life in performed stroke [km]

Open the catalog to page 12

Screw jacks with travelling ball nut (Mod.B) 3.9 Ball nut life Ball screw diameter 25 - 32, accuracy grade IT 3 or IT 5 Following life diagrams refer to a constant applied load, without shocks and 90 % ball screw reliability. For different load and/or reliability conditions, please refer to ch. 1.11 “Ball screw life calculation” on page 18 or contact SERVOMECH. 25 20 Life in performed stroke [km]

Open the catalog to page 13All Linearmech Srl catalogs and technical brochures

-

Ball Screw Jacks

128 Pages

-

Linearmech - Catalogue 2012

81 Pages

-

LME12 Catalog

2 Pages

-

LME11 Catalog

2 Pages

-

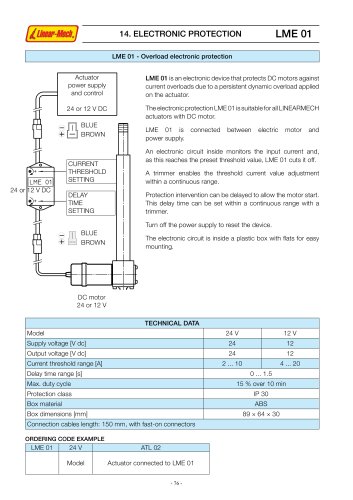

LME01 Catalog

1 Pages

-

MR40FC Catalog

2 Pages

-

MR31 Catalog

2 Pages

-

MR15 Catalog

2 Pages

-

UBA0 Catalog

4 Pages

-

CLB27 Catalog

3 Pages

-

CLB25 Catalog

5 Pages

-

BSA12 Catalog

3 Pages

-

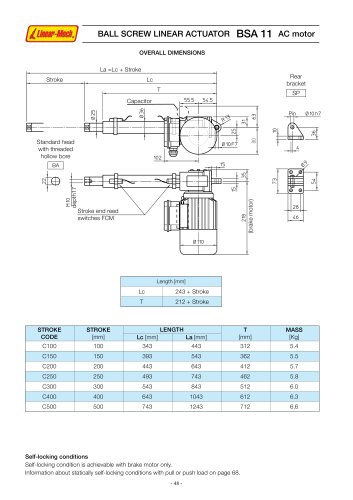

BSA11 Catalog

5 Pages

-

BSA10 Catalog

6 Pages

-

BSA08 Catalog

3 Pages

-

UAL0 Catalog

4 Pages

-

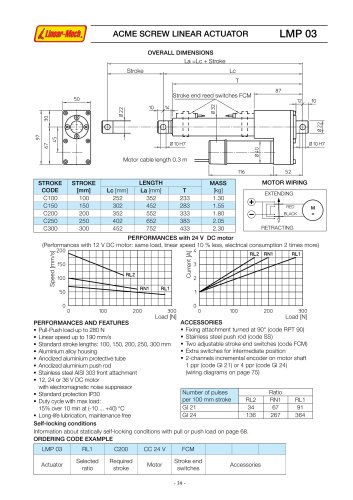

LMP03 Catalog

3 Pages

-

LMI02 Catalog

2 Pages

-

CLA28 - CLA28T Catalog

5 Pages

-

CLA20 Catalog

3 Pages

-

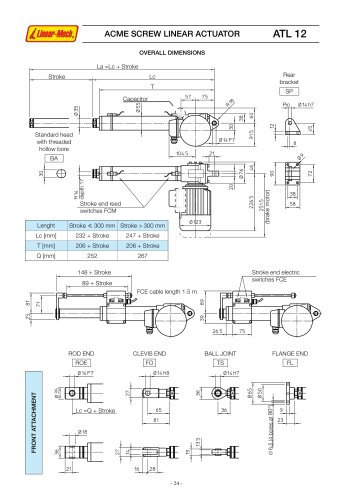

ATL12 Catalog

3 Pages

-

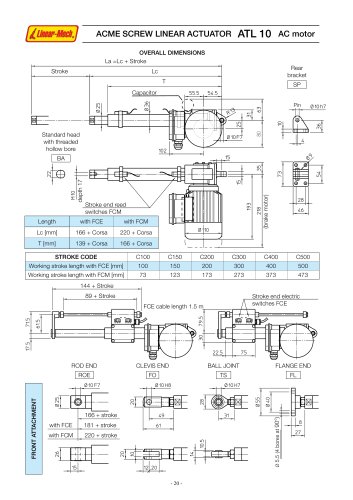

ATL10 Catalog

6 Pages

-

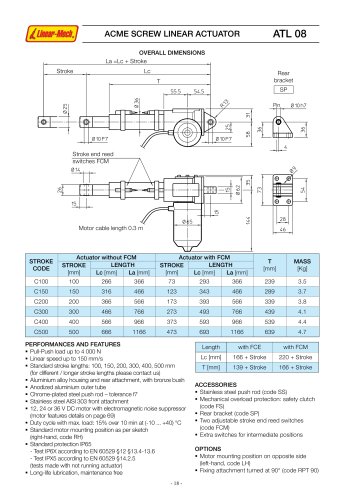

ATL08 Catalog

3 Pages

-

ATL05 Catalog

3 Pages

-

ATL02 Catalog

3 Pages

-

LMR03 Catalog

4 Pages

-

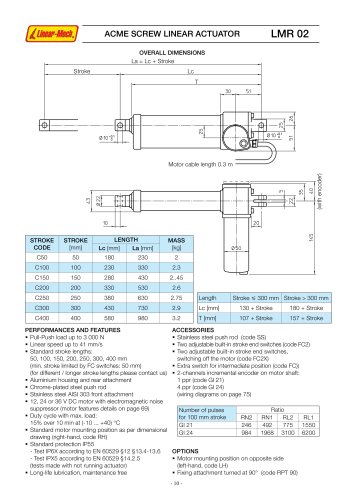

LMR02 Catalog

4 Pages

-

LMR01 Catalog

4 Pages