Catalog excerpts

PRESS RELEASE THE NEWS IN BRIEF Innovation is a constant factor for Servomech Group, since 1989 specialized in the design and construction of linear actuators, ball screw jacks, acme screw jacks, ball screws and nuts. The company presents to the market a new universal motor adapter that allows to combine the high performance of Servomech screw jacks with the servomotors of the main brands on the market. NEW SOLUTIONS FOR SERVOMECH SCREW JACKS WITH BRUSHLESS SERVOMOTORS Servomech expands the application possibilities of its high performance screw jacks, now prepared for the assembly of all the main servomotors on the market and promotes a new concept in lifting systems Among the innovations implemented by Servomech, a new universal motor adapter is now available to be combined with the range of ball screw jacks and acme screw jacks, thus allowing to combine the high performance mechanics of Servomech with the servomotors of the main brands in trade. The new motor adapters for brushless servomotors, like the whole range of Servomech products, are always made inside Servomech factory in Anzola dell’Emilia (Bologna - ITALY) and are available as standard components with a great advantage in terms of faster delivery times and competitive costs. Considering an advanced industrial context, where more and more frequently the need for high speeds and continuous operations, as well as load and positioning control, the designers evaluate with great interest solutions with higher performances, easier to control (position, load and speed), and able to guarantee a competitive advantage in terms of quality and quantity of the work performed. Servomech, which has always been at the forefront in the search for new solutions for linear motion, promotes a new concept in lifting systems, with an innovative approach, focused on the application of its high-performance ball screw jacks, with brushless motors and related drives and controls. Customers and designers are free to choose the brand of motors and drives they prefer. Thanks to the new universal motor adapter, the motor connection is now optimized for the use of servomotors with square flange, allowing a simple and immediate coupling with all the main servomotors on the market. The next generation of lifting systems proposed by Servomech allow you to reach high linear speeds, high dynamic operations with relevant acceleration and deceleration, high positioning accuracy, exact position repeatability and operations with a continuous duty cycle. The synchronism between the various lifting points is carried out in the electrical axis, with the control in position or in both position and torque. The use of ball screw jacks equipped with servomotors, absolute multiturn encoders and drives capable of managing the motion capability of the motors and the control of the required current, allow for reaching high speed, precision and repeatability performance. Servomech presents a new universal motor adapter allowing to combine the high performance mechanics of Servomech with the servomotors of the main brands in trade

Open the catalog to page 1

PRESS RELEASE The traditional lifting systems are in low linear speed applications, with intermittent operating cycles, preferably with the use of acme screw jacks. Through different configurations depending on the needs and dimensions and through the mechanical connections with connecting shafts, mechanical couplings and motion transmission reducers, the screw jack with motor transmits the movement to the other lifting points through a mechanical synchronism. This solution has some limits, mostly related to linear and rotation speed, inertia masses involved and the lost power in the various...

Open the catalog to page 2All Linearmech Srl catalogs and technical brochures

-

Ball Screw Jacks

128 Pages

-

Linearmech - Catalogue 2012

81 Pages

-

LME12 Catalog

2 Pages

-

LME11 Catalog

2 Pages

-

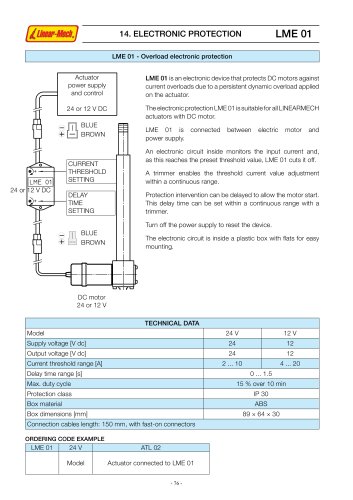

LME01 Catalog

1 Pages

-

MR40FC Catalog

2 Pages

-

MR31 Catalog

2 Pages

-

MR15 Catalog

2 Pages

-

UBA0 Catalog

4 Pages

-

CLB27 Catalog

3 Pages

-

CLB25 Catalog

5 Pages

-

BSA12 Catalog

3 Pages

-

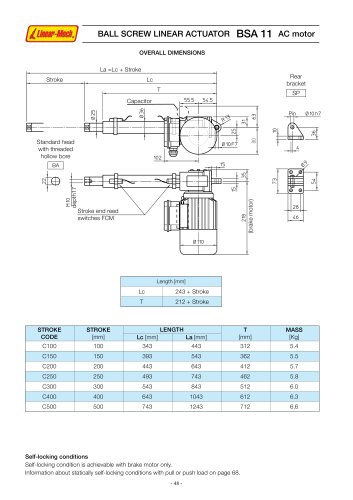

BSA11 Catalog

5 Pages

-

BSA10 Catalog

6 Pages

-

BSA08 Catalog

3 Pages

-

UAL0 Catalog

4 Pages

-

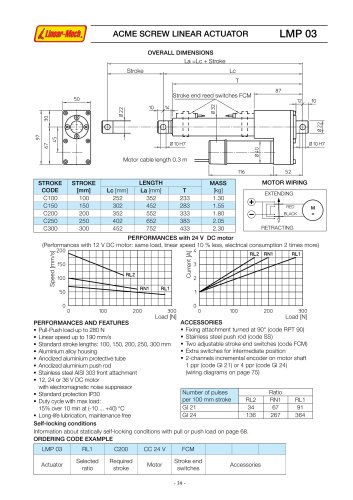

LMP03 Catalog

3 Pages

-

LMI02 Catalog

2 Pages

-

CLA28 - CLA28T Catalog

5 Pages

-

CLA20 Catalog

3 Pages

-

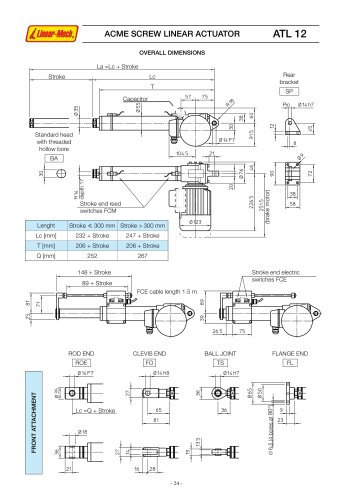

ATL12 Catalog

3 Pages

-

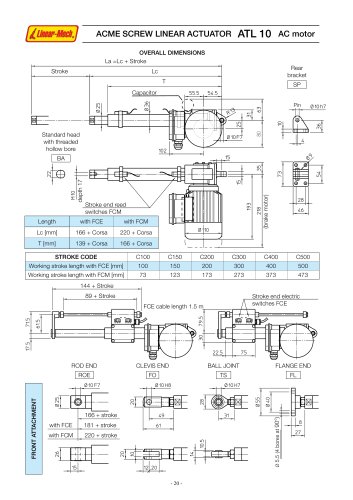

ATL10 Catalog

6 Pages

-

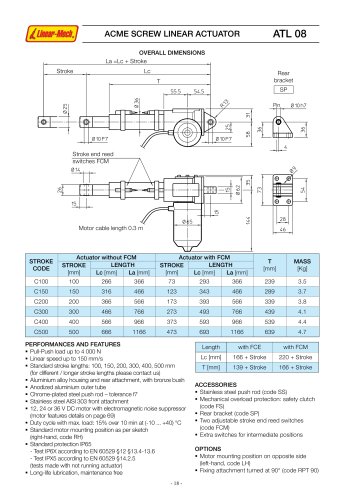

ATL08 Catalog

3 Pages

-

ATL05 Catalog

3 Pages

-

ATL02 Catalog

3 Pages

-

LMR03 Catalog

4 Pages

-

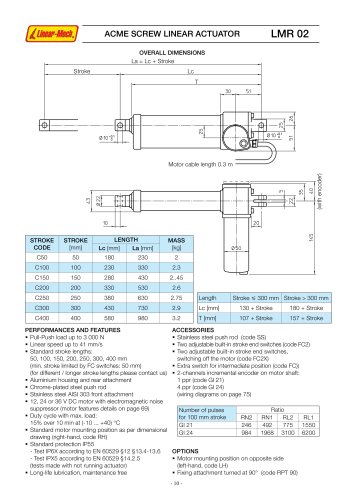

LMR02 Catalog

4 Pages

-

LMR01 Catalog

4 Pages