Website:

Linde Material Handling

Website:

Linde Material Handling

Group: LINDE

Catalog excerpts

Smart robotics solutions The Linde-MATIC range Linde Material Handling

Open the catalog to page 1

Linde robotics, an integrated smart solution This new robotic solution, the most advanced available today, provides for the first time incredible competitiveness gains and a unique flexibility for your operations. To ensure a fully integrated solution, our safety system protects continuously your environment: humans, goods and machines which are now able to all work together. Smart robotics solutions - The Linde-MATIC range

Open the catalog to page 3

Why robotics? While logistics tasks will always be directed by people, this new generation of robotic trucks can perform repetitive, low added value material handling tasks reliably and independently. Called “cobotics” the collaboration between people and robots allows both to work and interact together safely. Robotics also helps increase productivity and lower costs by reducing damage to goods and putting people at less risk of physical strain by giving uncomfortable tasks to the robotic truck. Robotics also improves the efficiency of material handling flows thanks to consistent timing...

Open the catalog to page 4

Smart robotics solutions - The Linde-MATIC range

Open the catalog to page 5

Our solution offers multiple benefits and cost savings Linde expertise and support ## Standard trucks: volume production, high-quality, proven reliability Comprehensive sales network, after-sales services and maintenance Proven expertise and market presence Technology performance ## ## Easy, fast integration into existing operations No infrastructure required providing the utmost flexibility Fully scalable solution

Open the catalog to page 6

Robots that can think and work autonomously alongside people Linde-MATIC robotic trucks are equipped with smart features allowing them to operate in the same environment alongside people and other vehicles without any additional infrastructure. The robots navigate using existing structural features such as walls, racking or columns: a solution that is economical, easy and quick to install and can easily accomodate future changes to routes or activities. Fast & easy to implement Standard vehicle & service Smart robotics solutions - The Linde-MATIC range

Open the catalog to page 7

Competitiveness: The most cost-effective robotic solution on the market By combining a unique navigation system with Linde’s expertise in material handling equipment, the Linde robotics truck range offers reliable solutions to help our customers optimize their in-house material flows and achieve major cost savings. Return On Investment (ROI): Rapid payback and massive TCO savings ## ## Reduced installation costs Massive savings on operating costs

Open the catalog to page 8

Improved costs structure Installation Installation Infrastructure Infrastructure Navigation Installation Navigation Standard Trucks with laser navigation Linde-MATIC geoguidance Smart robotics solutions - The Linde-MATIC range

Open the catalog to page 9

Innovative navigation and easy integration Navigation Navigation without infrastucture The innovative “Geoguidance” navigation system integrates easily into existing warehouses. Easy to install The system maps existing physical structures and quickly accommodates changes in the environment. Creating and modifying driving paths is fast and simple to implement. Real-time localization of robots Robotic trucks use a map of the environment to locate themselves in real time by comparing what the navigation laser detects with the reference map. 3 - path creation

Open the catalog to page 10

Integration The DRIVEN BY BALYO technology offers a complete logistics solution interfaced with customers’ own logistics management software ensuring real-time supervision. Based on Linde’s standard products, the robotic versions are equipped with dual mode commands (manual & automatic) so they can easily integrate into a customer’s existing operation. Dual mode: automatic or manual control If needed, an operator can take manual control of the robotic truck to perform ordinary manual tasks. Supervision & interface The Supervisor software provides overall management of the robotic truck...

Open the catalog to page 11

Linde’s best selling features, enhanced The safety features of Linde-MATIC trucks are based on a combination of best in class safety solutions used on Linde standard trucks with the addition of further innovative safety and detection features. Geoguidance laser (range in excess of 30 meters) 3D camera: obstacle detection, safety support Visual and acoustic warning indicators User Interface equipped with intuitive touch screen Emergency stop buttons Tiller: simply activating the buttons or the tiller itself stops the truck immediately and returns it to manual mode Restarting automatic mode...

Open the catalog to page 12

Front safety ## ## High safety level (Performance Level D) Dynamic and responsive The end of the safety versus productivity trade-off: unnecessary stops are avoided Autonomous decision-making Productivity gain Rear scanners ## ## ## High safety level (Performance Level D) Mobile load perception Pallet detection sensor Hardware safety features ## ## Emergency stop buttons Tiller switch Smart robotics solutions - The Linde-MATIC range

Open the catalog to page 13

A streamlined & versatile truck range With a comprehensive standard truck range, we cover 80% of all material handling applications in most manufacturing and logistics businesses. Load train applications Pick & drop at low levels Loads transport Conveyor to packing machine Waste management Order picking Feeding production lines Stock line management

Open the catalog to page 14

The combination of Linde’s standard trucks and Balyo’s unique technology enables us to offer our customers the real flexibility and versatility they need. Counterbalanced Stacker Pallet Truck Pick & drop of closed pallets Long distance load transfers Handling stillages and industrial containers Block stacking loads in marshalling areas Stacking onto conveyors Transferring long loads Smart robotics solutions - The Linde-MATIC range

Open the catalog to page 15

Linde Material Handling and BALYO are merging their technologies and strengths to develop innovative robotic material handling solutions. High quality products are matched by the standards of service that we provide. With a comprehensive network of local sales partners, we are available around the clock and around the world. Your local Linde partner offers a complete single-source package: from qualified pre-sales consulting to after-sales service, including financial packages matched to your business: leasing, rental or hire purchase. Flexibility is guaranteed to meet your operational and...

Open the catalog to page 16All Linde Material Handling catalogs and technical brochures

-

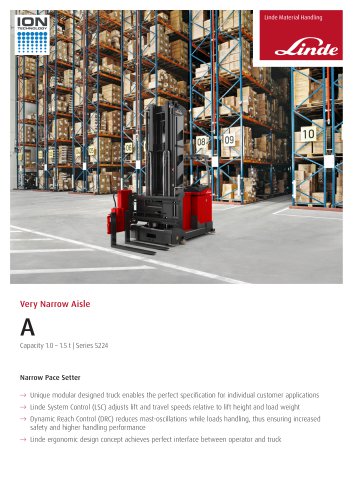

Very Narrow Aisle A

6 Pages

-

LT10 – LT20 C/B/BM

8 Pages

-

LT16 Ch/BMh

8 Pages

-

Product Portfolio

87 Pages

-

Truck Overview

8 Pages

-

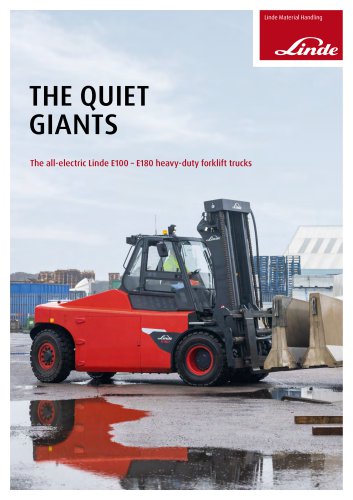

Heavy Trucks

16 Pages

-

Electric Forklift Trucks

40 Pages

-

Counterbalanced Forklift Trucks

40 Pages