Website:

Linde Material Handling

Website:

Linde Material Handling

Group: LINDE

Catalog excerpts

Standard Equipment Narrow chassis width 820mm Overhead guard Key switch or PIN Code access Soft landing on forks Multifunction coloured display with Linde Load Management Floor compensator as well as hourmeter, maintenance indication, battery dischar- Linde Load Management (Standard): ge indicator and internal fault code indication Automatic residual capacity calculation Power assisted steering Operator warning when approaching the limits Automatic speed reduction when cornering Traction speed is varied automatically in proportion to the ECO-Mode with up to 12% energy savings steering angle for maximum safety 3 kW AC motor (maintenance free) Drive wheel Polyurethane Drive wheel position mentioned in display Single load wheel Polyurethane Lateral battery change 3PzS available with ergonomic battery Chassis for load arm width 560 & 680mm un/locking with lever & rollers (l2=1037mm) Lifting systems 3 Lift control provides accurate lifting as well as smooth, quiet operation 3 Soft landing on forks protects the load when lowering 3 Initial lift independent of main lift (option) 3 Max. lift height up to 5316mm 3 Max. load capacity in Stacker use: 1,400kg/1,600kg on load arms Ergonomics 3 Ergonomic operator compartment with standard fabric seat or leather seat available with three independent adjustments systems 3 Seat heating available as option 3 Metal handle with padded material & adjustable floor plate designed for easy truck access 3 Side-stance position 90° allows excellent visibility in both directions Seated Pallet Stacker Capacity 1,400 & 1,600 kg L14 R, L16 R Handling 3 Chassis width = 820mm 3 High maneuverability when operating in lorries or confined spaces 3 Stable 4 point configuration 3 TipControl®: traction, lift controls, initial lift and horn grouped in one single ergonomic unit 3 Enables one-handed operations 3 Height adjustable hand platform Linde Load Management 3 Standard or Advanced, the load management system assists control of residual capacity and stability 3 Standard: Weight estimation of the load carried up to 1500mm 3 Advanced: Immediate calculation of load weight and lifting height 3 Information available at a glance on a wide multifunctional display Drive control and settings 3 Steering effort adjusts automatically to speed and turning radius 3 Speed is automatically reduced in relation to the steering angle 3 ECO-Mode up to12% energy savings to finish shift with low battery status Workstation 3 Multifunctional instrument display with user-friendly menu structure 3 Truck access control by PIN code or ignition key 3 Support clipboard DIN A4, flashing beacon & panoramic mirror available as option 3 Emergency isolator located for instant actuation Comprehensive energy solutions 3 24V batteries : capacities from 345 Ah (3PzS) to 500 Ah (4PzS) 3 Standard Lateral change including rollers inside the battery compartment to aid battery change 3 Lever initiates battery change preventing direct contact 3 Li-ION batteries with 4,5KWh(205Ah) and 9,0kWh(410Ah) 3 Rapid full charge in 1h30min with optimized charger AC motor 3 Powerful, 3 kW drive motor 3 Moisture and dust proof AC drive motor is maintenance-free 3 Gradient performance of max. 15% (laden) 3 No roll back on gradient starts 3 High torque motor negotiates loading docks with ease Optional Equipment Initial lift (h5=125mm) Mast Protection: polycarbonate, steel mesh Ultra fast lifting (up to +40%) Speed reduction if forks lowered Linde Load Management Advanced: Alternative fork carriage length/thickness: High productivity combined with safety. The operator’s Live calculation of weight and height body remains within the chassis contours at all times and Informs on potential maximum height & weight is also protected by an overhead guard. The Linde Load Management of the remaining residual capacity Linde Connected Solutions: Management system automatically calculates residual capa- Drive wheels: cushion rubber, synthetic cushion rubber non ac: access control (PIN or RFID Dual), an: usage analysis and city and warns the operator when approaching load limits. Automatic floor compensating system ensures the truck‘s Load wheels: tandem polyurethane, tandem polyurethane and Flashing beacon Support Clipboard DIN A4 & panoramic mirror Lateral battery change 4PzS available with ergonomic battery Support data terminal incl. power supply cable 24V un/locking with lever & rollers (l2=1112mm) Mobile or Fixed battery stand One of the trucks many benefits is its high productivity ponents make this a truck that can be relied on. Motor, Leather seat & seat heating Automatic battery watering system performance, with a 3 kW AC motor enabling speeds up to sub-components and electronics are all protected within the Various Standard, Duplex & Triplex masts (up to 5316mm lift Cold store protection -35°C 10km/h. The robust chassis structure provides exceptional robust chassis structure. With the initial lift version(option), the Other options available on request residual capacities, with nominal capacities from 1,400kg ground clearance is improved to cope with gradients and dock up to 1,600kg. The truck chassis width of 820mm, combined Subject to modification in the interest of progress. Illustrations and technical details could include options and not binding for actual constructions. All dimensions subject to usual tolerances. Standard Equipment /Optional Equipment levellers. These features guarantee a longer operating life combined with safe, efficient and highly productive load handling. Reliability Rugged construction and the use of tried and tested com- Li-ION Batteries with intuitive operating controls, delivers excellent manoeu- Rapid Full Charge vrability in confined areas. Opportunity Charging includes battery housing extra weight Rapid Intermediate Charging Li-ION charger Maintenance Free optimized 24V-Charger v255: full charging time 1h30min The 90° seating position and a seat with three independent tive maintenance routines. Easy access to all components and Extended Lifetime adjustments provides an excellent working posture, and the maintenance-free technology also play their part in increasing Efficient performance in Cold Stores integrated, and highly functional, operating controls, ensure truck uptime and availability. CAN bus connectivity provides Side Plug available a superb working environment. The compartment floor plate a computerised diagnostic system for rapid analysis to ensure maintenance intervals are also minimised for maximum uptime. Service Efficiency at work and efficiency in servicing with cost effec- Linde Material Handling GmbH, Postfach 10 01 36, 63701 Aschaffenburg, Germany Phone +49.6021.99-0, Fax +49.6021.99-1570, www.linde-mh.com, info@linde-mh.com

Open the catalog to page 1All Linde Material Handling catalogs and technical brochures

-

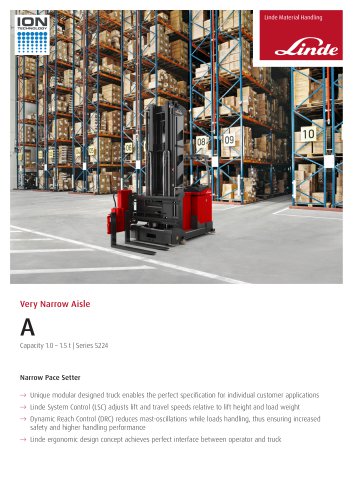

Very Narrow Aisle A

6 Pages

-

LT10 – LT20 C/B/BM

8 Pages

-

LT16 Ch/BMh

8 Pages

-

Product Portfolio

87 Pages

-

Truck Overview

8 Pages

-

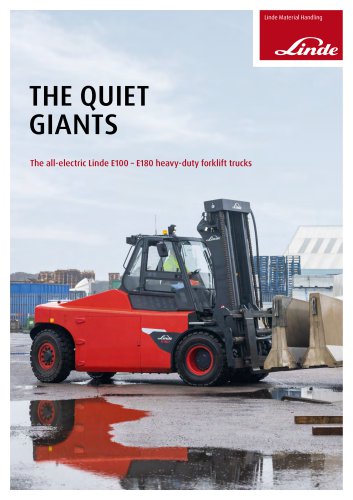

Heavy Trucks

16 Pages

-

Electric Forklift Trucks

40 Pages

-

Counterbalanced Forklift Trucks

40 Pages