Website:

Linde Material Handling

Website:

Linde Material Handling

Group: LINDE

Catalog excerpts

ONE RANGE FITS ALL Custom Picking Solutions from Linde Material Handling

Open the catalog to page 1

EFFICIENCY UP, COSTS DOWN As a logistics professional, you know all too well: There is hardly any other process so crucial to productivity, efficiency and profitability as manual picking. At the same time, hardly any other process offers so many optimization opportunities, beginning with the selection of an order picker tailored to your needs. Which is why Linde Material Handling offers you not only the broadest range of trucks worldwide for horizontal and vertical man-to-goods picking at a height of up to 12 meters; but also allows you to choose from the most diverse truck models,...

Open the catalog to page 3

PROCESS OVERVIEW ATTENTION TO DETAIL. PERFECTED PROCESS. Confirm the order, drive to the rack, remove product, load on the product carrier and then r epeat. Manual picking, whether at ground or height level, continues to be as important to logistics as the rack and warehouse. Picking is time consuming, piecemeal and physically d emanding for employees. Yet it offers manifold possibilities for increasing efficiency. A look at the numbers shows that: A good 75 percent of the time spent per picking job is exclusively devoted to stop-andgo work at the racks. And because this action is repeated...

Open the catalog to page 4

PROCESS OVERVIEW A CLOSER LOOK AT THE PICKING CYCLE Pre-Picking Pre-pic king Assignment S et-up pallets for roll containers Travel to picking area Order-Picking Travel between picks Stop and pick The actual picking process makes Close roll containers Travel to shipping area Deposit and label load Return 55% ORDER PICKING → Pre-pick identification and post-pick check (20%) → Picking and loading on pallet (35%) 20% ASSOCIATED TASKS → Assignment → Set up pallets for roll container → Pallet wrapping → Depositing load in shipping area 25% TOTAL TRAVEL → Travel in the picking area is limited to...

Open the catalog to page 5

YOUR NEEDS – OUR SOLUTIONS SOUGHT AFTER, FOUND There's no question about it. Even if the picking process itself is always the same, a wide range of different factors must be considered from warehouse to warehouse. This includes the specific modalities concerning the flow of goods, such as the type of good, the necessary picking frequency and the number of pallets on which the good is loaded. Spatial conditions also play an important role. How is the rack system constructed? Are the aisles wide or narrow? How long or short are the transport routes between the staging and picking area? Each...

Open the catalog to page 6

EXCELLENCE IN ALL DISCIPLINES From home improvement stores to food wholesalers, from the automobile industry to contract logistics – everywhere where goods and products are manually picked, the following applies: High productivity is key. It is precisely for that reason that we consider all factors that contribute to this ultimate goal when we develop our order pickers. This takes the form of carefully thought out features shared by different models that allow your employees to work as ergonomically, safely, efficiently and effectively as possible. ERGONOMICS Ergonomics is the basic...

Open the catalog to page 8

EFFICIENCY Manual picking is one of the most labor and cost intensive processes. Each second that your employee can pick faster will pay off. This begins with driving around the warehouse. Our order pickers reach top speeds of up to 14 km/h, while their excellent maneuverability also reduces driving time. And one must not forget about the employee. Order pickers precisely tailored to warehouse-specific pick requirements make work substantially easier and significantly boost picking rates. There is no need to compromise when selecting an individually fitting order picker. We offer trucks...

Open the catalog to page 9

Horizontal Picking 0 – 2,500 kg max. load capacity

Open the catalog to page 10

STRONG SIBLINGS You need a high-performance ground-level order picker for conventional man-to-goods applications that enables your employees to work quickly, afely s and ergonomically. We know: In order to achieve this goal, it is crucial to closely consider the individual conditions surrounding your picking processes. That's why we have developed two truck variations in the N20 and N20 C series, one with the driver's platform in front and one with the driver's platform in the conventional position behind the battery.

Open the catalog to page 11

TWO CONCEPTS WITH MULTIPLE VERSIONS The models in the Linde N20 and N20 C series are precisely adaptable to your application needs and enable you to remain completely flexible in addressing the requirements of your warehouse and the needs of your employees. They are ideal for ground-level picking and route transport. BETTER VISIBILITY; SAFE OPERATION This is possible due to a truck architecture that is unique on the market. With the N20, the operator stands in front of the battery rather than behind it, as is the case in the conventional design. This gives the operator an unhindered view of...

Open the catalog to page 12

DOES WHAT IT SHOULD LIFTING POSSIBLE The N20 C is a true all-rounder in the warehouse and is ideal if you are looking for a picking solution that scores as high on performance as it does on efficiency. Your operators will also benefit from Linde's commitment to excellence when it comes to handling and ergonomics, thanks to intelligently located handles or the optionally available driver platform with air suspension. To save space, more and more warehouses place pick positions not only at the lowest rack level but also at the one above it. To handle this, you can order a liftable driver's...

Open the catalog to page 13

The N20 and N20 C ground-level order pickers boast many distinctive features to meet individual needs. And yet both series have interchangeable integrated features. That translates into high operability, easy serviceability and top performance. AT YOUR FEET Even though operators can get on the order pickers from both sides, it is often simpler not to get on the truck when traveling short distances. For these situations, the N20 and N20 C have a pedestrian function allowing the operator to walk beside the truck. Push buttons mounted on both sides of the truck allow the operator to control...

Open the catalog to page 14All Linde Material Handling catalogs and technical brochures

-

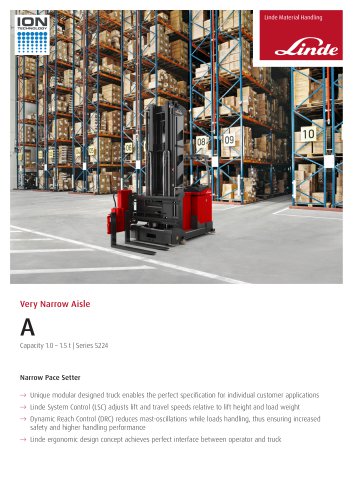

Very Narrow Aisle A

6 Pages

-

LT10 – LT20 C/B/BM

8 Pages

-

LT16 Ch/BMh

8 Pages

-

Product Portfolio

87 Pages

-

Truck Overview

8 Pages

-

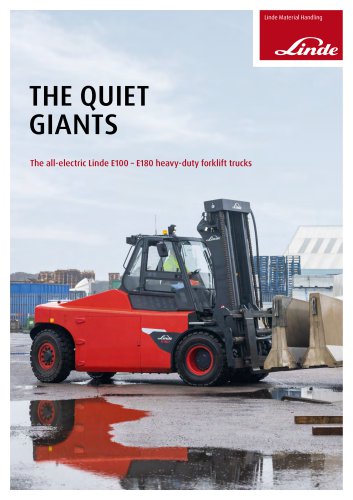

Heavy Trucks

16 Pages

-

Electric Forklift Trucks

40 Pages

-

Counterbalanced Forklift Trucks

40 Pages