Website:

Linde Material Handling

Website:

Linde Material Handling

Group: LINDE

Catalog excerpts

Logistic Train Solutions LT10 – LT20 C/B/BM Capacity 1.0 – 2.0 t | Series 8970-01 Future-proof tugger train combining outstanding safety and flexibility → Efficient solution for bundling ground-level transports of large quantities of materials over long distances → Flexible combination of different frame variants for transporting different loads and goods → Compatible to LMH trolleys or adaption to customer-specific load carriers → Can be operated with both manual and automated tow tractors and thus be integrated into digit

Open the catalog to page 1

TECHNICAL DATA (According to VDI 2198) Representative models have been used for simplicity. For final data, which may vary depending on customer-specific scope and configuration, please contact your local distributer. Load capacity / Load Service weight Tyres: solid rubber, superelastic, pneumatic, polyurethane Tyre size, front Tyre size, rear Wheels, number front/rear Tread, front Tread, rear Overall height Lift function Height drawbar Coupling height Loading height, unladen Height, lowered Length of loading surface Width of loading surface Overall length Overall width Fork dimensions...

Open the catalog to page 2

AISLE WIDTHS Total loads per train Total train length / mm Frame size Total frames per train Frame type 180°-CURVES (SAMPLE AISLE CHANGE) e1 = Aisle width before / after curve e2 = Aisle width along curve c = Distance between aisles 1) When the middle support is completely moved to side 2) In combination with a P40 C B / P40 C / 60 C of series 4595. Remark: Values are calculated; final values may differ slightly 3) In combination with a P60 / P80 of series 1191. Remark: Values are calculated; final values may differ slightly 4) Without a safety space. We recommend to add a safety space of...

Open the catalog to page 5

LOGISTIC TRAIN SYSTEM OVERVIEW FRAMES C-Frame

Open the catalog to page 6

STANDARD AND OPTIONAL EQUIPMENT Model / Equipment Both-sided load handling with trolleys while loading Both-sided load handling with pallets while loading and unloading (upon request) Mechanical load protection with automatic locking after insertion Travel prevention with lowered frames and deactivated lowering function during travel Two-axle-design with central load space and wide wheelbase for high driving safety Patented lifting mechanism of forks with tilt function for continuous ground clearance Weather protection with one or two openings to secure loads in outdoor applications...

Open the catalog to page 7

CHARACTERISTICS Ergonomics → Ideal support of the driver with load handling at ground level and convenient control of the lifting function with different modes → Fork ejection mechanism on C-Frames and push-through-option on Bridge-Frames for ergonomic support during handling of also heavy loads → Simple and quick coupling of frames via plug and play → Low-noise trains with electrical lifting function reduce acoustic stress Fork unlocking device with ergonomic fork ejection mechanism on LT-C Handling → Precise maneuverability and smallest turning radius thanks to the 4-wheel-steering which...

Open the catalog to page 8All Linde Material Handling catalogs and technical brochures

-

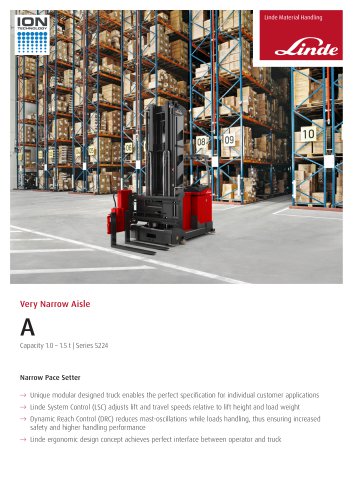

Very Narrow Aisle A

6 Pages

-

LT10 – LT20 C/B/BM

8 Pages

-

LT16 Ch/BMh

8 Pages

-

Product Portfolio

87 Pages

-

Truck Overview

8 Pages

-

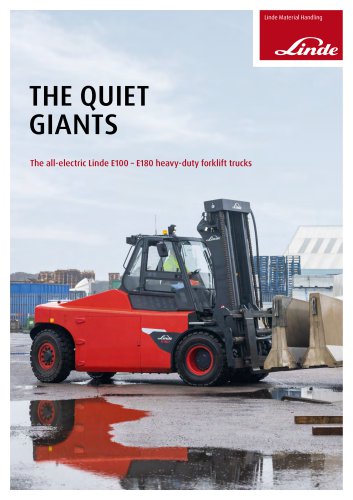

Heavy Trucks

16 Pages

-

Electric Forklift Trucks

40 Pages

-

Counterbalanced Forklift Trucks

40 Pages