Catalog excerpts

¨¨ Acetylene Acetylene The fuel gas of choice.

Open the catalog to page 1

Consult the experts. Finding the fuel gas that works best for you. Your choice of fuel gas is fundamental to the quality, safety, efficiency and cost-effectiveness of your fabrication processes. Whether you are cutting, brazing, heating, cleaning, gouging etc., you need to be sure that you are using the best fuel gas for your business. However, there are many fuel gases available: LPG (propane), natural gas (methane), acetylene and so on. So how do you select the correct fuel gas for your needs?¨ ¨ Linde can help you make the right decision. With our extensive application experience and...

Open the catalog to page 2

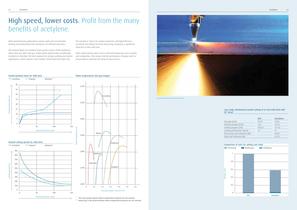

High speed, lower costs. Profit from the many benefits of acetylene. Most manufacturing applications require rapid and concentrated heating and preheating of the workpiece for efficient operation.¨ ¨ The primary flame of acetylene heats up the surface of the workpiece faster than any other fuel gas, reducing the preheat time considerably. Acetylene is therefore the best solution for cutting, welding and related applications, which require a fast transfer of heat from the flame into ¨ ¨ ¨ Mechanised oxy-acetylene cutting the workpiece. Due to its unique properties and high efficiency,...

Open the catalog to page 3

When less means more. Reduced gas consumption with acetylene. When reducing processing costs, total gas consumption is an important factor to consider. In this regard, acetylene is the best fuel gas you can get. ¨ ¨ When using acetylene, there are two savings. On the one hand, you need less fuel gas, due to the shorter preheat time and faster processing. And on the other hand, you also save oxygen, as a lower mixing ratio of acetylene and oxygen is necessary to generate a normal cutting flame (see table below).¨ ¨ Some processes, such as brazing and preheating, do not require such high...

Open the catalog to page 4

Results that make the difference. Achieve a superior performance with acetylene. Acetylene enhances the performance of many applications and thus helps achieve the high-quality results that keep you ahead of your ¨ competition. Below are a few examples: ¨¨ Compared to other fuel gases, acetylene produces very low moisture levels, making it the only suitable gas for preheating, welding or brazing high-strength materials. ¨¨ Thermal welding and cutting processes induce residual stresses in the workpiece that lead to distortion. Only an acetylene flame can produce the precisely concentrated...

Open the catalog to page 5

Safety features come built in. Wherever you are, you can rely on acetylene. When using fuel gases in confined spaces or underground, acetylene is the only fuel gas considered suitable. This is due to its physical properties, i.e. it is 10 % lighter than air. Therefore, a dangerous accumulation of flammable gas at ground level is prevented.¨ ¨ As with all fuel gases, acetylene needs to be treated with respect. Fuel gas applications are associated with potential sources of hazards, such as fire and fumes, requiring special care as well as corresponding safety systems and equipment that meet...

Open the catalog to page 6

Efficiency you can rely on. The right supply solution. The best fuel gas has to be complemented with the right supply mode. Using our years of experience, we will offer the most cost-efficient solution – from small cylinders to road trailers.¨ ¨ In addition, we will also provide you with the necessary equipment (automatic changeover manifolds and point-of-use regulators) and design, install and maintain gas distribution systems that comply with current safety standards.¨ ¨ No matter how much gas you demand, we can ensure a flexible and reliable supply – with minimum disruption to your...

Open the catalog to page 7

Saving time and effort for your core business. Add our tailored services to your gas solution. Today’s market is becoming increasingly competitive, meaning that you need to concentrate on adding value to your business.¨ ¨ At Linde, we offer you more than supply services. We have a whole portfolio of service offers to make your life easier and ensure that you are up to date with the latest technology and safety standards. We can also provide assistance with production issues and help you run your business as efficiently as possible.¨ ¨ For those applications where an off-the-shelf solution...

Open the catalog to page 8

12345678 1209 – 1.X L&P With its innovative concepts, Linde is playing a pioneering role in the global market. As a technology leader, it is our task¨ to constantly raise the bar. Traditionally driven by entrepreneurship, we are working steadily on new high-quality products¨ and innovative processes.¨ ¨ Linde offers more. We create added value, clearly discernible competitive advantages, and greater profitability. ¨ Each concept is tailored specifically to meet our customers’ requirements – offering standardised as well as customised ¨ solutions. This applies to all industries and all...

Open the catalog to page 9All Linde Gas catalogs and technical brochures

-

Overview of Shielding Gases

12 Pages

-

propane

1 Pages

-

lindoflamm_flame_solutions

2 Pages

-

hydrogen

2 Pages

-

acetylene

2 Pages

-

ETO

3 Pages

-

DA

2 Pages

-

Cl2

3 Pages

-

NH3

3 Pages

-

C2H6

3 Pages

-

CO

2 Pages

-

D2

2 Pages

-

Ar

2 Pages

-

Air

2 Pages

-

Liquid Helium - He

2 Pages

-

Carbon Dioxide -CO2

3 Pages

-

Liquid Argon - Ar

2 Pages

-

linde annual 2009

96 Pages

-

AXENIS Water Treatment

8 Pages

-

LINSPRAY Thermal Spray Solutions

16 Pages

-

LINDOFLAMM Brochure

12 Pages

-

Bottom Injection systems

2 Pages