Catalog excerpts

PRODUCT CATALOGUE Welding & Cutting

Open the catalog to page 1

SPEEDTEC PULSE RANGE ® ULTIMATE PERFORMANCE EXCELLENT PRODUCTIVITY RUGGED RELIABILITY SUPERIOR ERGONOMICS NEXT GENERATION

Open the catalog to page 2

TABLE OF CONTENTS MIG CONVENTIONAL EQUIPMENT OPTIONS Overview Compact Separate MIG Welding Guns & Accessories Accessories MIG & MULTI PROCESS INVERTER WELDERS Overview MIG Inverter Welders Multi Process Inverter Welders Advanced Process Welders Wire Feeders MIG Welding Guns & Accessories Accessories PLASMA TORCHES EDUCATION SOLUTIONS SEMI AUTOMATIC WIRE FEEDERS Overview Digital Analogue Accessories TIG WELDERS Overview TIG DC / Single Phase Inverter Welders TIG DC / Three Phase Inverter Welders TIG AC/DC / Single Phase Inverter Welders TIG AC/DC / Three Phase Inverter Welders TIG Torches...

Open the catalog to page 3

PICTOGRAM MEANING Single phase input power 15-110 Volt DC Wire feeder input power Three phase input power For constant voltage MIG, flux-cored and subarc processes 40 Volt DC Wire feeder input power Single or three phase input power For multi-process constant current or constant voltage applications Direct current welding output 24-42 Volt AC Wire feeder input power Power factor control Alternating or direct current welding output 34-44 Volt AC Wire feeder input power CrossLinc® Technology For constant current stick and TIG processes 42 Volt AC Wire feeder input power Engine Driven: Diesel...

Open the catalog to page 4

Wire Drive System Warranty (years) Max wire spool size (mm) Mode / Polarity PROCESS Number of voltage steps Rated Output MIG Separate Powertec® 305S Powertec® 365S Powertec® 425S Powertec® 505S CV425 CV510

Open the catalog to page 6

Processes MIG, Flux-cored (Innershield) Applications • Small maintenance and repairs • Garage works Superbly simple, powerfully portable. y ompact, portable, lightweight and easy to use. C y ontinuous wire feed speed adjustment and four selectable voltage settings for precise control. C y uitable for the welding of most thin sheet steel applications. S y onnects to 230V, 16 amps outlets. C y erfect for routine, small maintenance projects. P Parts & Labour OT CE PLUS PR Year warranty x Input cable (2.5 m) with 16 A plug x Fixed MIG gun (2.5 m) x Fixed return welding cable (2.5 m) x...

Open the catalog to page 7

Processes MIG, Flux-cored Applications • General Fabrication • Construction site • Maintenance and Repair • Light industry Powerful, compact, economical. y xcellent starting performance (stable and dynamic). E y oltage selectors with multiple settings for precise adjustment. V y xcellent drive system with large diameter drive roll. E y quipped with large diameter wheels, push/pull bar and lifting eyes for full manoeuvrability. E y roducts developed with a focus on applications. P UNIT INCLUDES Parts & Labour OT CE PLUS PR x Undercarriage x Input cable (5 m), no plug x Work clamp and...

Open the catalog to page 8

Processes MIG, Flux-cored Applications • Heavy Fabrication • Structural • General Fabrication • Shipbuilding Powerful potential. y uperb arc behaviour with argon mix and 100% CO₂. S y oltage selectors with multiple settings for precise adjustment. V y wo choke tabs to support superb Arc behaviour. T y ynergic settings for easier control with LF24M Pro. S y right, digital volt and ammeter with LF24M and LF24M Pro. B y arge diameter wheels, push/pull bar and lifting eyes. L y imple water cooling conversion with Cool Arc® 25 (except PT 305S). S y an as needed (F.A.N.™). F Input Output...

Open the catalog to page 9

Processes MIG, Flux-cored Applications • Heavy Fabrication • Structural • General Fabrication • Shipbuilding High Output. Reliable Workhorses! y uperb arc behaviour with argon mix and 100% CO₂. S y ifferent feeders for construction and shipyards, all with meters, with or D without synergy or memory; just select the one of your choice. y ll controls on feeder close to the welder. A y quipped with large diameter wheels, push/pull bar E and lifting eyes for full manoeuvrability. y otted and encapsuled printed circuit board controls P in separate, dust-free compartments. UNIT INCLUDES x...

Open the catalog to page 10

rating calculated using CO₂ air cooled water cooled More details page 85

Open the catalog to page 11

Interconnection cables WATER Product Water cooler COOL ARC® 25 Adapter for wire spool 300 mm Adapter for wire spool 300 mm K14073-1 CO₂ supply socket heater connection kit Lincoln Analogue-Digital Interface * see chapter "Options" for details

Open the catalog to page 12

MIG & MULTI PROCESS INVERTER WELDERS

Open the catalog to page 13

Max wire spool size (mm) Synergic V/A meters CrossLinc ArcLink® Digital Communication Warranty (years) Weld Pak™ 2000 Speedtec® 180C Speedtec® 200C Speedtec® 215C Speedtec® 320CP Speedtec® 320CP Push-Pull Speedtec® 400SP Speedtec® 500SP Flextec® 350X Construction Flextec® 350X Standard Flextec® 500X Flextec® 650X Wire Drive System GMAW PULSE FCAW-G FCAW-S SMAW CAG (Gouging) DC TIG Lift Submerged Arc Powertec® i250C Standard Powertec® i320C Standard Powertec® i250C Advanced Powertec® i320C Advanced Powertec® i380C Advanced Powertec® i450C Advanced Powertec® i350S Powertec® i420S Powertec®...

Open the catalog to page 14

POWERTEC® i250C & i320C STANDARD MIG welder ready for tomorrow. y remium arc performance with repeatable arc ignition, excellent P arc stability and rapid parameter adjustment. y IG/MAG and STICK process. M y nnovative, intuitive interface: simple navigation, I easy settings and process selection. MIG & MULTI PROCESS INVERTER WELDERS Processes MIG, Flux-Cored, Stick Applications • General Fabrication • Construction site • Maintenance and Repair • Light industry Input y erfect feedability: optimised wire positioning, P N E LEC Parts & Labour OT CE PLUS PR four driven rolls and inspection...

Open the catalog to page 15

Processes MIG, Flux-Cored, Stick, CAG (only i450C) Applications • General Fabrication • Construction site • Maintenance and Repair • Light industry MIG welder ready for tomorrow. y EW features: Date&Calendar, Speaker and stronger encoders. N y remium arc performance with repeatable arc ignition, excellent P TFT 7’ colour screen, USB connectivity. y erfect feedability: optimised wire positioning, P four driven rolls and inspection window. y ater version: ready to connect COOL ARC® 26 cooler. W y esigned with welders for welders: perfect D handling, innovative and easy communication. y ...

Open the catalog to page 16All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

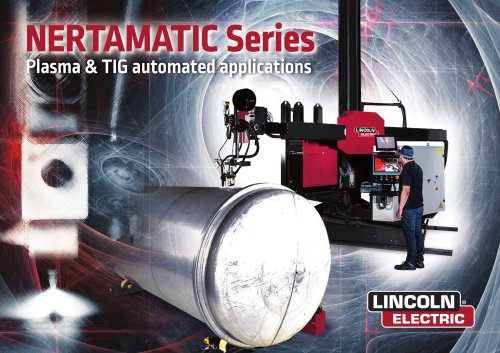

AUTOMATIC WELDING & CUTTING

92 Pages

-

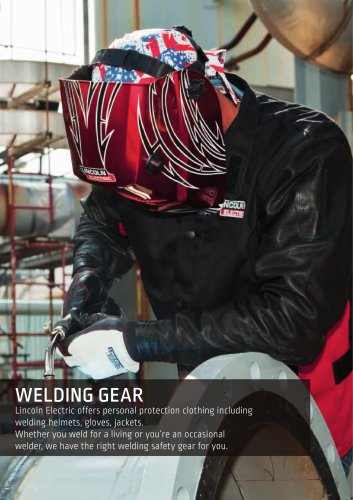

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

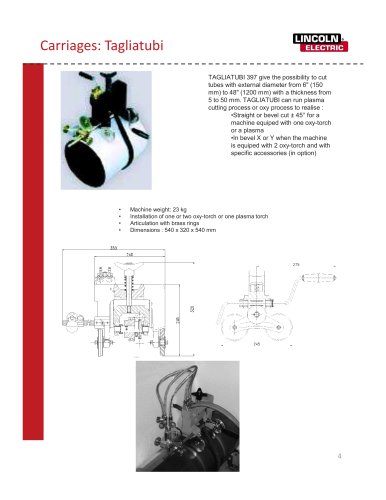

Carriages: Tagliatubi

1 Pages

-

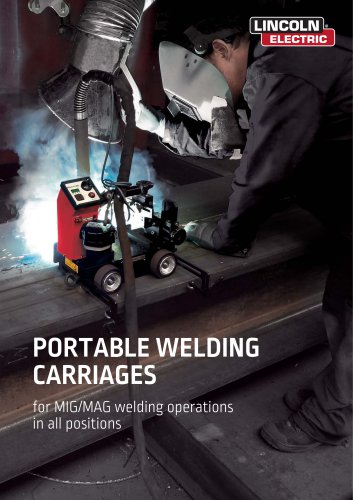

PORTABLE WELDING CARRIAGES

4 Pages

-

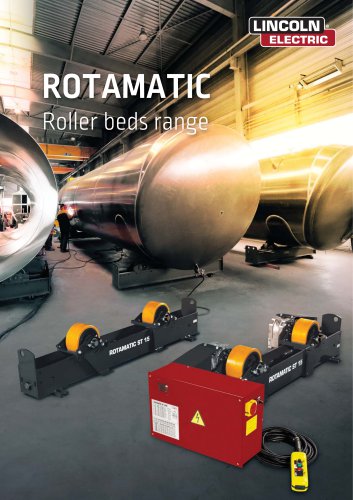

ROTAMATIC Roller beds range

4 Pages

-

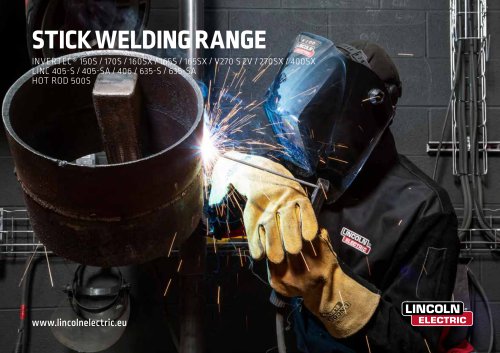

STICK WELDING RANGE

16 Pages