Catalog excerpts

STICK WELDERS WELD FUME CONTROL Reduces Welding Fume and Dust in The Workplace Portable, Wall-Mounted or Shop-Wide Systems

Open the catalog to page 1

WELD FUME CONTROL Lincoln Electric offers a complete line of portable, stationary and engineered solutions for welding fume control – mobile, stationary, downdraft and engineered systems. Mobile Mobile welding fume extractors with filtration are lightweight and rugged and are designed for light to medium duty welding fume extraction. The portable, lightweight solution is for the removal and filtration of welding fumes. This solution is ideal for facilities that require welding fume extraction in multiple locations. Downdraft Lincoln Electric’s DownFlex® table are dual purpose work bench and...

Open the catalog to page 2

WELD FUME CONTROL Mobile / Portable Units Lightweight, rugged design, low vacuum/high volume filtration system designed for extraction and filtration of welding fume. Ideal for facilities that require welding fume extraction in multiple locations, including maintenance departments, general fabrication and job shops and industrial welding environments. Perfect choice for small shops or companies with few welding stations, yet lightweight and small enough to be easily carried to the welding area. Portable Units The Miniflex® is ideally used for: • Contractors • Maintenance Workers • Small To...

Open the catalog to page 3

WELD FUME CONTROL Mobile Units The Mobiflex® is ideally used for: • Small Manufacturing Facilities • Schools / Training • Fabrication • Plant Maintenance & repair Portable Welding Fume Extractors The Mobiflex® 200-M, 300-E and 400-MS are low vacuum systems for welding fume extraction and filtration. Their size and mobility make them ideal for smaller manufacturing facilities that require light to medium duty welding fume extractionin variable locations. Mobiflex® 100-NF Portable fan Hose – Ø 203 mm Portable extraction fan with a free-blowing capacity of 2400 m³/h. Including 6 m mains cable...

Open the catalog to page 4

WELD FUME CONTROL Stationary Units Wall mounted, low vacuum systems are designed for extraction and filtration of welding fume. When used in conjunction with the LFA series of arms they provide welders with optimal motion and reach for their specific welding position(s) and work area. Ideal for a variety of facilities including maintenance departments, general fabrication and welding job shops, weld schools and industrial welding environments. The Statiflex® is ideally used for: • General fabrication • Welding schools • Maintenance departments Wall-Mounted Welding Fume Extractors The...

Open the catalog to page 5

WELD FUME CONTROL Downdraft Tables Lincoln Electric’s DownFlex® table are dual purpose work bench and extraction units, designed specifically for the removal of welding fume at the source. It can also be used to remove particulate and dust from metal grinding applications and light duty plasma arc cutting. The DownFlex® downdraft table is ideally used for: • Welding • Plasma Cutting Not suitable for grinding Aluminium, Magnesium, or other explosive materials Dual Purpose Workbench & Extraction Tables The DownFlex® table is a compact table that can be placed in multiple locations around a...

Open the catalog to page 6

WELD FUME CONTROL Modular Extraction Hood An Innovative and Flexible Solution to Efficient Weld Fume Control COMBINING INNOVATION AND SIMPLICITY, THE LINCOLN ELECTRIC MODULAR EXTRACTION HOOD PROVIDES A FLEXIBLE AND EFFICIENT OPTION FOR WELD FUME EXTRACTION IN A WORK ZONE WITH AUTOMATED EQUIPMENT. The Modular Extraction Hood is an easy to install, customizable enclosure that helps provide a cleaner work environment for a variety of industrial processes. Designed and built to Lincoln's rugged and dependable standards, these units are ideal for robotic and hard automation applications. The...

Open the catalog to page 7

WELD FUME CONTROL The Diluter™ System Free standing general filtration system The Diluter™ is a free-standing general filtration system that reduces the overall concentration of welding fume through continuous filtration and airflow. The product has been designed exclusively for extracting and filtering welding fume which is released during the most common welding fabrication processes. The system supplements the natural ventilation (draft) and/or forced ventilation (roof / wall fans) which may be present to reduce the overall concentration of welding fume in the workshop. THE FOUR MAIN...

Open the catalog to page 8

WELD FUME CONTROL Push-Pull System The solution for indoor air pollution in the industry Extraction at source is impossible when welding large pieces of metalwork or when the welder needs to change his welding location frequently. In such cases, aerial extraction is the only way to tackle the layer of welding fumes. Lincoln developed the extremely effective push/ pull-system especially for this purpose. Lincoln’s push/pull-system consists of 4 components: 1. Extraction (Pull): To move and extract the layer of particulate in a controlled direction, an extraction duct is designed according to...

Open the catalog to page 9All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

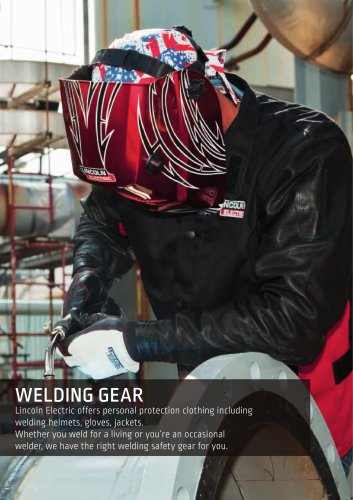

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

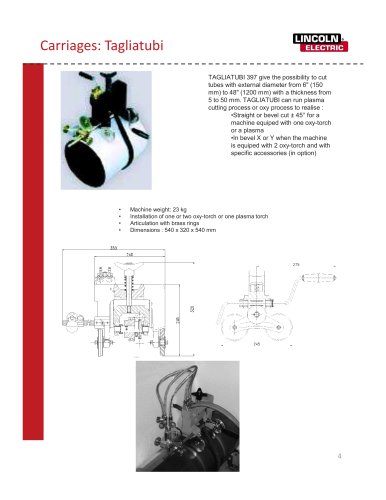

Carriages: Tagliatubi

1 Pages

-

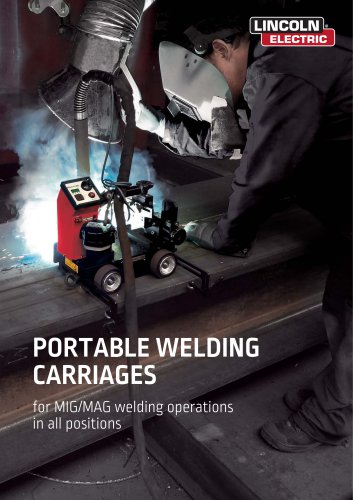

PORTABLE WELDING CARRIAGES

4 Pages

-

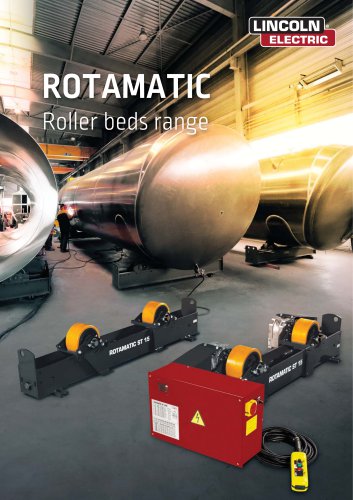

ROTAMATIC Roller beds range

4 Pages

-

STICK WELDING RANGE

16 Pages