Catalog excerpts

MicroGuard® Ultra – Enhanced Feedability Surface Lubricant MicroGuard® Ultra surface treatment, with proprietary arc enhancement agents, facilitates excellent weld puddle control, very good wetting action, straight bead edges and a wider operating range Customers that use it are saying: – Keeping the same voltage, we obtain improved productivity – Increase in the travel speed – We notice less spatters in the piece and contact tip. – Better arc stability WELD FASTER WITH THE SUPRAMIG® Result of controlled laboratory travel speed study 20% (standard application) TRAVEL SPEED INCREASE UNIQUE...

Open the catalog to page 2

TIGHT QUALITY CONTROL LINCOLN ELECTRIC RANGES We fix tighter ranges in the chemical composition and control more elements than required by AWS & ISO. Specific additional elements control VERY STRICT QUALITY CONTROL SYSTEM Quality MIG wire starts with quality raw materials • teel is comprised of many elements, some of which are undesirable for welding. We fix S tighter ranges on our steel components and control more elements than required by EN ISO • teel is the highest contributing factor to MIG wire performance S • ot all steel mills know how to produce quality wire rod for drawing a...

Open the catalog to page 3

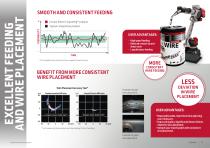

Lincoln Electric Supramig® product Typical competitive product USER ADVANTAGES: • High speed feeding • Reduced contact tip and linear wear • Long distance feeding EXCELLENT FEEDING AND WIRE PLACEMENT SMOOTH AND CONSISTENT FEEDING TIME * est to define the variation of force needed to feed the wire. T CONSISTENT WIRE FEEDING BENEFIT FROM MORE CONSISTENT WIRE PLACEMENT Wire Placement Accuracy Test* Standard market MIG wire DEVIATION IN WIRE PLACEMENT Example of poor wire placement Lincoln Electric MIG wire USER ADVANTAGES: • Repeatable welds. Spend less time adjusting your robot part. • I...

Open the catalog to page 4

The excellent starting position minimizes the level of spatter in intensive short weld designs and reduces dressing and reworking. SUPRAMIG® HD WEIGHT SPATTER / WELD WEIGHT (%) NORMALIZED SPATTER % Competitor 2 Competitor 3 PRODUCT USER ADVANTAGES: • • • • • Reduce component rework Minimize change over/nozzle cleaning cycles Reduced jig and tool cleaning frequency Improved life of contact tip and nozzle Consistent gas coverage MINIMAL SILICATE ISLANDS AREA OF SILICATE ISLANDS IN % OF TOTAL WELD AREA SUPRAMIG® HD ONLY ADDITIONAL FEATURES www.lincolnelectriceurope.com SILICATE ISLANDS Welds...

Open the catalog to page 5

TEST RESULTS Test results for mechanical properties, deposit or electrode composition and diffusible hydrogen levels were obtained from a weld produced and tested according to prescribed standards, and should not be assumed to be the expected results in a particular application or weldment. Actual results will vary depending on many factors, including, but not limited to, weld procedure, plate chemistry and temperature, weldment design and fabrication methods. Users are cautioned to confirm by qualification testing, or other appropriate means, the suitability of any welding consumable and...

Open the catalog to page 6All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

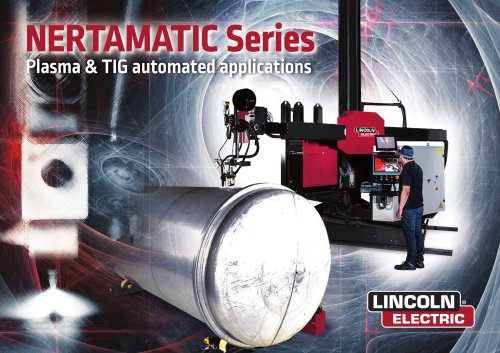

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

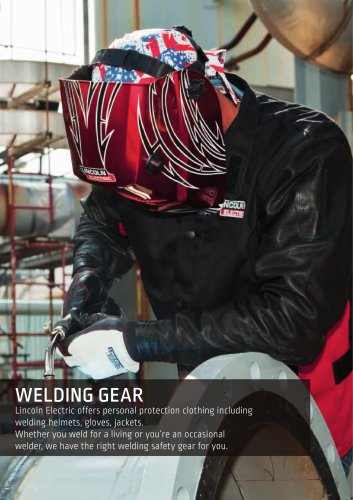

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

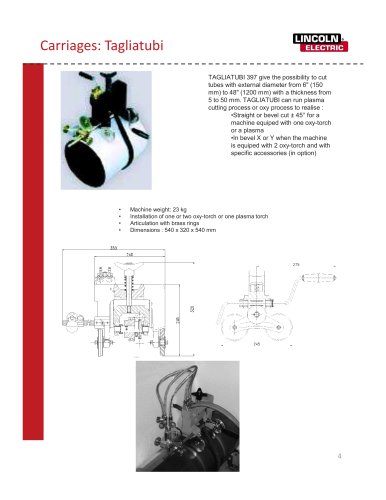

Carriages: Tagliatubi

1 Pages

-

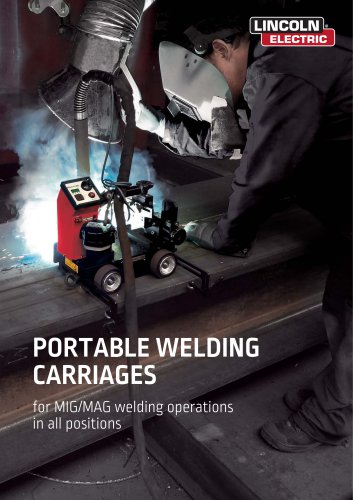

PORTABLE WELDING CARRIAGES

4 Pages

-

ROTAMATIC Roller beds range

4 Pages

-

STICK WELDING RANGE

16 Pages