Catalog excerpts

STICK WELDING RANGE

Open the catalog to page 1

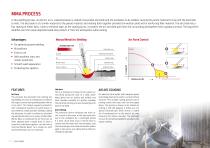

MMA PROCESS In this welding process, an electric arc is created between a coated consumable electrode and the workpiece to be welded, causing the parent material to fuse and the electrode to melt. The electrode is of a similar material to the parent material, and melting both together provides the weld (or joint) with a reinforcing filler material. The electrode has a flux coating of either basic, rutile or cellulose type. As the coating burns, it protects the arc and weld pool from the surrounding atmosphere with a gaseous shroud. The slag which solidifies over the newly deposited weld...

Open the catalog to page 2

STICK RANGE

Open the catalog to page 3

INVERTEC® 150S Small, powerful and robust • Robust design - Unique rubber corners, metal housing and push control buttons to withstand tough environmental conditions. • Premium arc - Advanced Lincoln technology and knowhow guarantee performance every time. • Power Surplus - Additional power for superior arc control. • Soft and Crisp mode - Selectable arc modes for different electrode types. • Auto Adaptive Arc Force - For stable arc with low spatter levels as standard. Year warranty Processes Stick, Lift TIG Applications • Small maintenance • Light construction • Light metal fabrication •...

Open the catalog to page 4

INVERTEC® 160SX Professional Performance Industrial Innovation INVERTEC® 165S & 165SX More Power- 30% more output current with the same input current allows welding with up to 4,0mm electrode from a 16A input. Portable Everywhere - Lightweight, easy to handle; able to operate with up to 100m mains extension cables and suitable to use with a generator. Robust Design, Industrial Use - Electrical safety (IP23), potted PC boards and optimum airflow reduces contamination to extend the equipment's lifespan in the harshest environmental conditions. Excellent Welding Experience - Good arc ignition...

Open the catalog to page 5

INVERTEC® V270S2V Powerful portability, robust reliability • Smart switching 230 / 400V three phase. • Excellent arc characteristics. • Maximum output of 270 amps allows the use of electrodes up to 6,0 mm. • Excellent rutile, basic and cellulosic stick welding performance. • Adjustable “Arc Force" and “Hot Start” as standard. Processes Stick, EL cellulosic, Lift TIG DC Applications • Pipeline • Heavy fabrication • Plant construction • Pressure vessels • Nuclear power station • Shipbuilding • Hardfacing • Process industry Unit Includes Input cable [2 m] Carrying strap Professional welder...

Open the catalog to page 6

COSNISTENCY - the same control of the entire range STICK RANGE LINC® 635-SA Control Panel

Open the catalog to page 8

LINC® 405-S & SA The rugged and distinguished workhorses • Rugged, conventional rectifier with excellent arc characteristics. • Capable of welding with Rutile, Basic and Cellulosic electrodes. • Arc gouging capability. • Easy-to-understand, graphic control panels. • Ready to be moved. Equipped with wheels, pull bar and two lifting hooks. Year warranty Processes Stick, EL cellulosic, Gouging Applications • Pipeline construction • Heavy industrial fabrication • Plant construction • Pressure vessels • Nuclear power station • Shipbuilding • Hardfacing • Process industry • Arc-Air gouging Unit...

Open the catalog to page 9

LINC® 635-S & SA The rugged and distinguished workhorses • Rugged, conventional welding rectifier with excellent arc characteristics. • Capable of welding with Rutile, Basic and Cellulosic electrodes. • Arc gouging capability. • Easy-to-understand, graphic control panels. • Ready to be moved. Equipped with wheels, pull bar and two lifting hooks. HOT ROD500S Year warranty Labour L Processes Stick, EL cellulosic, Gouging Applications • Pipeline construction • Heavy industrial fabrication • Plant construction • Pressure vessels • Nuclear power station • Shipbuilding • Hardfacing • Process...

Open the catalog to page 10

STICK ELECTRODES MILD STEEL STICK ELECTRODES OMNIA®46 AWS A5.1: E6013 ISO 2560-A: E 38 0 R 1 1 AC / DC - • Applicable for “clean” structural steel. • Smaller dimentions - excellent for hobbyists. • Very suitable for low open circuit voltage transformers [min. OCV 42 V). Double Coated Electrode • Easy ignition, easy to restart - to restrike arc. • Much easier vertical up vs basic electrode. • Soft arc fusion, extremely good weldability. • Few spatters, no need to rework, no sticking. • Easier to weld especially with poor joint preparation. • Universal basic electrode, most suitable for...

Open the catalog to page 12

STAINLESS STEEL STICK ELECTRODES WITH LOW CR(VI) EMISSION RATE 304L / 308L High operator appeal and control due to the more stable and focused arc transfer. Reduced welding fumes [up to -40%] and lower hexavalent Cr content [up to -60%]: improved working environment for all workers in the workshop. Suitable for root pass. Lower porosity, good striking and restriking, excellent slag removal STAINLESS STEEL STICK ELECTRODES FOR STEELS DIFFICULT TO WELD 316L • Excellent for repair welding. • Especially developed for steels difficult to weld, such as armour plates, austenitic Mn-steels and high...

Open the catalog to page 13

y Easy to handle. y Suitable to weld all types of metals. y Universal – can be used anywhere, any time. y The best choice for outdoor activities – welding with gas won’t produce good results in windy conditions. y Delivering quality welding and decent mechanical properties. y Easy to learn. y Relatively quiet. y Inexpensive to procure. y Insensible to contamination, such as rust, oil or grease. PRODUCT APPLICATION CHART ADVANTAGES OF ELECTRODE WELDING Stainless Steel High recovery Arc gouge HEAVY APPLICATIONS Applications Pipeline Shipbuilding Heavy fabrication Hardfacing Plant...

Open the catalog to page 14

www.lincolnelectric.eu STICK RANGE

Open the catalog to page 15

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements. Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.eu for any updated information. CUSTOMER ASSISTANCE POLICY The business of The Lincoln Electric...

Open the catalog to page 16All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

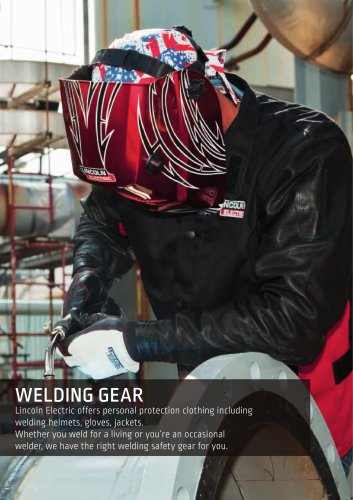

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

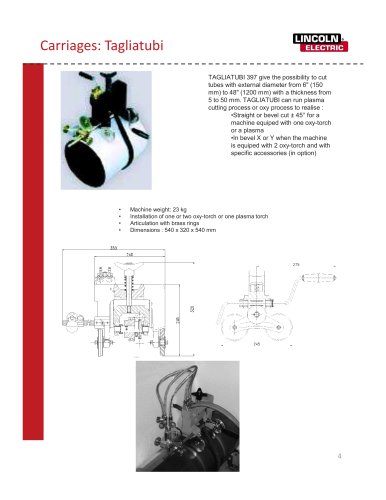

Carriages: Tagliatubi

1 Pages

-

PORTABLE WELDING CARRIAGES

4 Pages

-

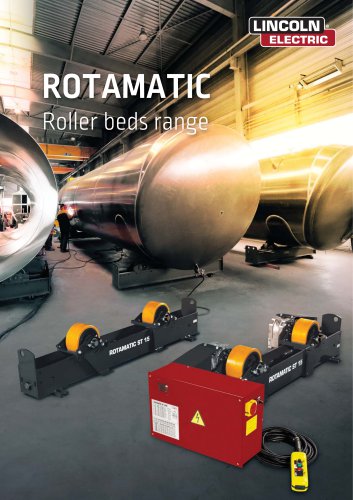

ROTAMATIC Roller beds range

4 Pages