Catalog excerpts

PROCESS PIPING 4.0 THE NEXT STEP IN MECHANIZATION

Open the catalog to page 1

TOTAL SOLUTION CUTTING MECHANIZATION WELDING EQUIPMENT WELDING CONSUMABLES EDUCATION Industry Challenges Piping Solution – The Next Level Pipefab, One Machine From Root To Cap Mastering Data – Software Solution The Next Dimension In Premium Wires Everything From One Hand – One Stop Solution Experts Summary PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS

Open the catalog to page 2

BEING PRESENT LOCALLY MAKES US MORE AWARE GLOBALLY Benefit from the Market Leader NETHERLANDS UNITED KINGDOM UNITED STATES ITALY CHINA UAE MEXICO INDIA Global Headquarters Solution Centers UNITED KINGDOM EMPLOYEES WORLDWIDE FRANCE UNITED STATES ARGENTINA RUSSIA Global Headquarters Solution Centers INDIA COLOMBIA SOLUTION CENTERS SOUTH AFRICA PERU BRAZIL CHILE SOUTH AFRICA AUSTRALIA PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS

Open the catalog to page 3

EVOLUTION Lincoln Electric is the world leader in the design development & manufacture of arc welding products and equipment, robotic welding systems and PLASMA/OxyFuel cutting equipment, along with the newly introduced mechanized welding systems for the welding of Process & Power piping. Customer focus is one of Lincoln Electric’s key goals in providing new and existing customers with “Value Added Propositions” to increase their productivity and business growth. PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS With 325+ Research and Development Engineers worldwide and 36 Welding...

Open the catalog to page 4

INDUSTRY AND CUSTOMER FOCUS TECHNICAL SUPPORT & AFTERSALES SERVICE Application & standards, WPS development RELIABILITY & PRODUCTIVITY First pass yield, welding quality, consistency, project timeline & costs INDUSTRY CHALLENGES TRAINING High dependence on manual welding LABOUR SKILLS Lack of experienced welders WHAT IS PROCESS PIPING? WE PROVIDE THE FULL SOLUTION PACKAGE Process Piping commonly refers to a network of piping systems that transports industrial gases, fuels, water or steam, around industrial facilities, installations or pipelines associated with the manufacture of products....

Open the catalog to page 5

PIPING SOLUTION THE NEXT LEVEL PIPEFAB™ STT ROOT APEX/HELIX M85 MECHANISED FCAW FILL AND CAP ONE STOP SHOP Lincoln Electric is the only company providing customers the full process piping solution, improving productivity up to 10x DEPOSITION RATE VS SMAW WELDING MECHANISATION APEX/ HELIX M85 PACKAGE *these are typical cycle times tested in lab conditions PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS OPERATING FACTOR VS SEMI-AUTOMATIC PIPEFAB™ STT® ROOT + SMART PULSE™ FILL & CAP + P IPEWELD GMAW COLUMN AND BOOM OPERATING FACTOR VS SEMI-AUTOMATIC RATE YOUR SELF DEPOSITION RATE VS...

Open the catalog to page 6

IMPROVE YOUR TOTAL CYCLE TIME PER JOINT BY INCREASING YOUR DEPOSITION RATE PRODUCTION COSTS & DUTY CYCLE REDUCE YOUR PRODUCTION COSTS BY INCREASING YOUR OPERATING FACTOR TOTAL CYCLE TIME INCREASE AUTOMATION AND IMPROVE TOTAL CYCLE TIME PER JOINT PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS

Open the catalog to page 7

EXPERTISE • TECHNICAL SUPPORT • DEVELOPMENT OF WPS/PQR • EDUCATION & TRAINING PRODUCTION MONITORING ORBITAL SYSTEMS PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS

Open the catalog to page 8

PIPEFAB, ONE MACHINE FROM ROOT TO CAP Introducing the new pipe and pressure vessel dedicated multi processes welding machine Breakthrough Arc Performance From root, to cap, to final fit – the PIPEFAB™ system has you covered with weld modes that have been fine-tuned to deliver breakthrough arc performance specifically for pipe and vessel fabrication. Industry-Driven Design Like the name says, the PIPEFAB™ system was developed specifically for pipe and vessel fabrication. With its Ready-to-Run™ design, every detail was considered in creating the ultimate setup for the pipe and vessel...

Open the catalog to page 9

CHECKPOINT™ Good Data – Good Decisions With CHECKPOINT System • More than data collection • Full production monitoring • Identify the TRUE COST of welding • Evaluate the TRUE QUALITY of welding • Deliver the TRUE PERFORMANCE of welding PRODUCTION MONITORING FOR MORE INFORMATION SCAN HERE All PIPEFAB™ systems come ready to connect to powerful, yet simple-to-use software for configuration, updates and welt data monitoring. • Remote diagnostics & configuration • Free and easy software updates –never worry about swapping or storing memory cards. • CheckPoint® Production Monitoring Optimized Arc...

Open the catalog to page 10

A MULTI-PROCESS WELD HEAD DESIGNED FOR PIPE AND FLAT TRACK WELDING Operator pendant, Advanced Process Module, STT® Process Module, 15’ or 25’ welding torch, multiple pendant cable lengths, multiple power supply options, custom track rings SYSTEM OPTIONS • • • • GMAW GTAW Combination GMAW/GTAW Hot Wire GTAW • Multiple wire feeders for feeding in either direction • Magnetic arc oscillation to magnetically stir the puddle • FeatureKey software to secure weld programs • Upgrading to another process doesn’t require a new capital expense purchase • Operators trained for one process are already...

Open the catalog to page 11

THE NEXT DIMENSION IN PREMIUM WIRES FASTER ARC ESTABLISHMENT UP TO USER ADVANTAGES: NORMALIZED SPATTER % Our manufacturing facility in Nijmegan, Netherlands has over 70 years of experience producing high quality electrodes, cored and solid wires. We have recently invested in a state-of-the-art, fully automated production facility that manufactures premium stainless steel MIG/MAG, TIG & SAW wires. Narrow product specifications combined with the industry’s most extensive production and quality control processes help produce the unparalleled welding performance and consistency of Lincoln...

Open the catalog to page 12

WELDING RELIABILITY SAME MECHANICAL PROPERTIES The weld quality is crucial in Process Piping, and poor weld quality may impact your production time and cost. Mechanized welding can provide great benefits in these areas by helping improve repeatability, traceability, welding time, soundness and weld appearance. USER ADVANTAGES • WPS Adherence • Consistent Welding parameters application • Parameters Limits control • Traceable Weld Data PROCESS PIPING - THE NEX T DIMENSION IN PREMIUM SOLUTIONS

Open the catalog to page 13All Lincoln Electric Deutschland catalogs and technical brochures

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

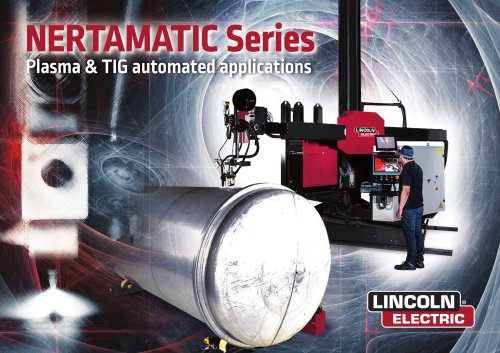

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

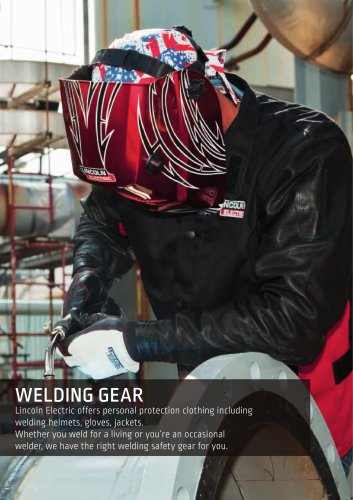

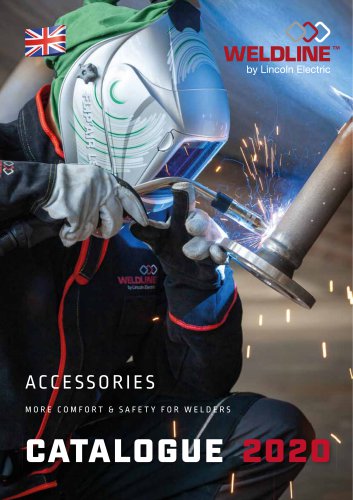

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

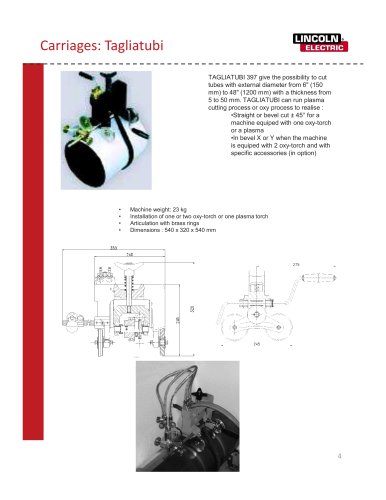

Carriages: Tagliatubi

1 Pages

-

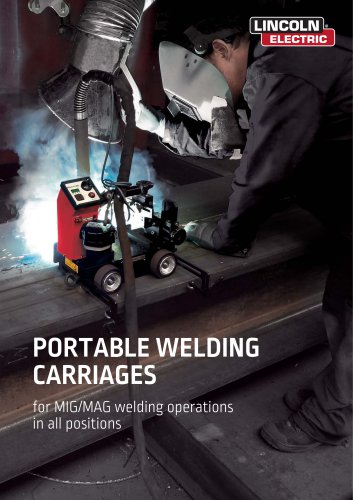

PORTABLE WELDING CARRIAGES

4 Pages

-

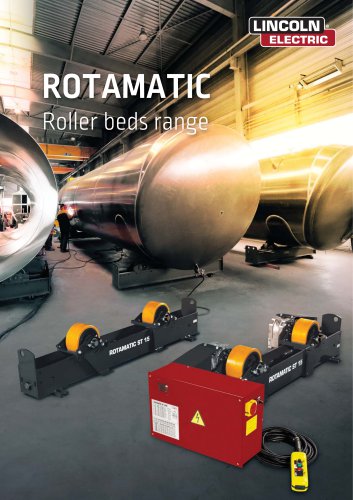

ROTAMATIC Roller beds range

4 Pages

-

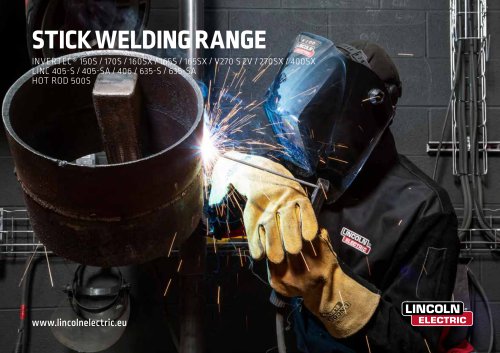

STICK WELDING RANGE

16 Pages