Catalog excerpts

COMPLETE SOLUTION FOR INDUSTRY POWERTEC®- i S RANGE Reliable workhorses are coming. They are as solid as always, more convenient than ever, and superbly productive. These products will help you get more things done. Based on modern inverter technology, they continue the well-established POWERTEC®-i series, which now offers separate wire feeders. This is another, decisive step into the future of professional welding. With a specially designed, rugged construction, which is subjected to a large variety of tests (Lincoln Electric TRUE HD), they are ready to work in even the most demanding...

Open the catalog to page 2

POWERTEC®- i S RANGE Input GENERATOR READY Parts & Labour Year warranty POWERTEC®-i S RANGE is a brand new range of Lincoln Electric products based on the latest inverter platform, combining modularity, ease of use and optimal MIG/MAG or MMA welding performance with excellent power cost efficiency. Three power sources: i350S, i420S and i500S with a choice of separate wire feeders, standard LF52D for basic use, or the advanced LF56D for more demanding applications, helps customer to fulfill every possible welding needs. All POWERTEC®-i S have the option of water cooling by simply adding the...

Open the catalog to page 3

NEW ERGONOMIC DESIGN Simple navigation also when using welding gloves Power Source water cooled ready (cooler COOLARC® 26 as option) Practical handle for effortless gripping even with gloves and safe movement of the machine Cable Management System (option) For easy transportation of the whole welding system even with very long connection cable Rotatable wire feeder Swivel on the power source enabling rotation of the wire feeder and setting it in any position Heavy duty undercarriage Extremely reliable and stable, passed incline stability tests on 15° gas cylinder entree makes loading very...

Open the catalog to page 4

LINCOLN RELIABILITY Cable connections on front (in standard) and back rear side (in option) All cable connections can easily be made without tools Practical, big storage locker inside the power source with key lock, internal lights, for accessories like gun, gloves, rolls, contact tips, etc. Large wheels for easily effortlessly overcome obstacles such as cables or thresholds Intermediate hose packages Heavy-duty protective hose and military-quality plugs Strain reliefs on both ends to keep connections well protected A wide range of lengths to choose (up to 30m), water or air...

Open the catalog to page 5

RELIABLE WORKHORSES High duty cycle 420A/100% (i420S & i500S) igh production efficiency H igital welding current control D rue HD tested – made for the harsh T environmental conditions Inverter engine technology – ECO Friendly ower power consumption thanks L to high efficiency – energy cost saving utomatic power-saving modes A (standby/shutdown function) enerator ready G Easy maintenance and servicing Easy access to all components inside Software update via laptop or USB (LF56D) Intelligent F.A.N. (Fan As Needed) in the inverter Variable speed controlled fan (energy-saving) Low pollution...

Open the catalog to page 6

OPTIMIZED ERGONOMICS Lifting eye – crane suspension For vertical and suspension operation For safe and easy transportation Gun Holder: always at hand, ready to work Front UI protection cover keep your UI safe Professional wire feeding system Four driven wire feed rolls Excellent wire feeding on every material Permanent internal lights Wire inching gas test toggle switch Dust-proof wire spool cover Inspection window indicates level of wire spool Simple and comfortable spool change New locking system – spool cover stays always closed Big wheels as standard for mobility Flowmeter for shielding...

Open the catalog to page 7

STATE OF THE ART TECHNOLOGY IN WIRE FEEDING Professional wire feeding system – robust and precise individually driven rolls for extremely stable wire feeding for various wire types 4 luminum housing for a long service life A roll diameter (37mm) for optimal wire feeding Big Simple, tool-free roll change Factory-fitted with rolls for 1,0mm and 1,2mm steel and stainless steel Steel Stainless steel Braze Flux cored Aluminium Wire feeder pressure set-up Connection for drum feed (optional adapter). Less need to change wire spools saves time Steel Stainless steel Braze 2,5 ÷ 3,5 Flux cored 1,5 ÷...

Open the catalog to page 8

DESIGNED TO ENHANCED YOUR WELDING CAPABILITY POWERTEC® I COMPACT RANGE

Open the catalog to page 9

INNOVATIVE INTUITIVE INTERFACES LF56D Innovative and easy communication Simple navigation also when using welding gloves wo controls, one button for easy navigation T language for key commands Icon RCFX™ – joint visualization A ork point in material thickness [mm] / WFS / A W ocking function / Limits / Memories / Jobs L anguages (tailor-made language version possible to add) L Easy process and settings selection Interface available in languages: English, German, France, Polish, Finnish, Spanish, Italian, Turkey, Russian, Dutch, Romanian, Slovakian, Hungarian, Czech, Turkish More functions &...

Open the catalog to page 10

LF 52D Intuitive and simple in use – reduced time for training Welding Process & Shielding Gas Selection Direct access to the most commonly used welding parameters: elding characteristics optimized W in terms of welding process (GMAW/FCAW or SMAW) selection and shielding gas type for the best dynamics and minimal spatter imple and quick selection S by pressing the button EDs showing the selected L rc dynamics (choke effect) from A soft to hard orch trigger mode 2-step / 4-step T un-in WFS – sets the wire feed R speed from the time the torch trigger is pressed until an arc is established...

Open the catalog to page 11

STANDARD VS ADVANCED Comparison of functions and features POWERTEC® I COMPACT RANGE UI type Display view configuration Auto settings Memory Jobs Limits Locking function Languages USB connectivity Media files (Support) Weld Logs / History Quick Triger Push-Pull gun Cross-switch gun A/B procedure Software version Factory Reset Inductance 2T/4T Gun mode Spot welding Gas purge test Cold Inch test Preflow time Run-in WFS Start procedure Crater procedure Burnback time Postflow time Hot Start (SMAW) Arc Force (SMAW) Welding Processes GMAW / FCAW Stick mode Synergic CAG

Open the catalog to page 12All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

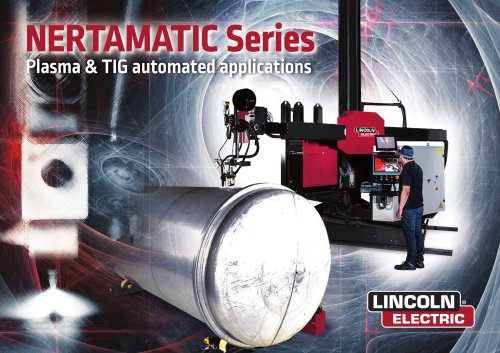

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

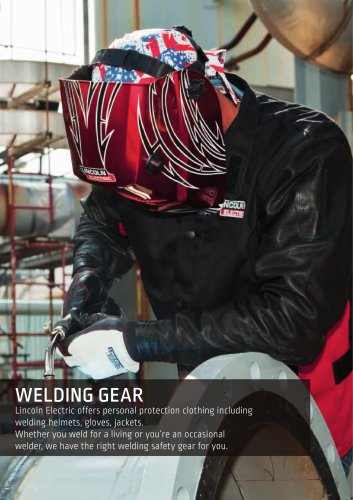

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

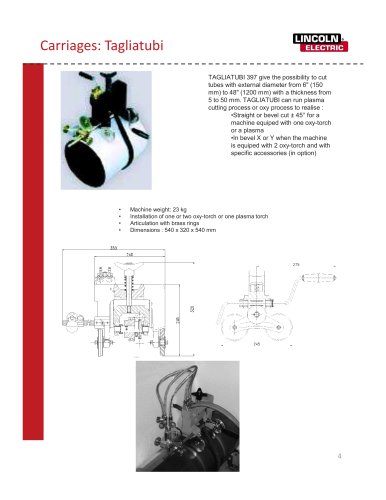

Carriages: Tagliatubi

1 Pages

-

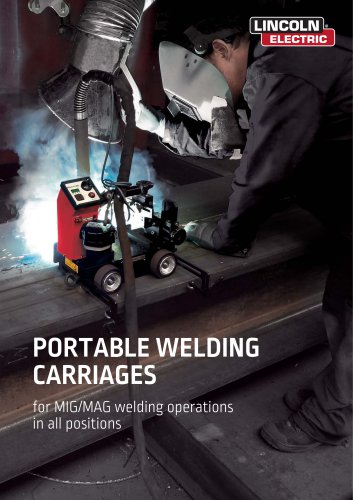

PORTABLE WELDING CARRIAGES

4 Pages

-

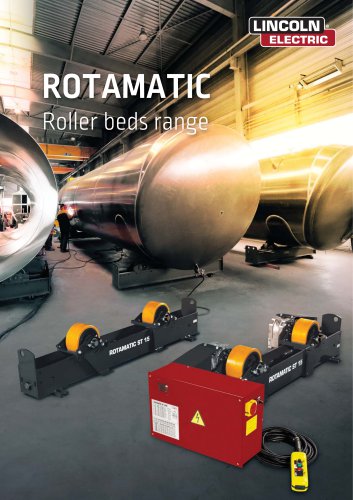

ROTAMATIC Roller beds range

4 Pages

-

STICK WELDING RANGE

16 Pages