Catalog excerpts

POWERTEC®- i COMPACT RANGE The POWERTEC® i COMPACTS RANGE is built on the latest Lincoln inverter platform, ensuring optimal MIG/MAG and MMA welding performance with excellent power and cost efficiency. The range consists of: 250A, 320A, 380A and 450A power sources with a choice of either the STANDARD panel (i250C & i320C) or the ADVANCED panel (i250C, i320C, i380C & i450C), that meet most customers' needs and covers a wide range of welding applications. The Plug & Play water cooler COOLARC® 26 is available for POWERTEC® i380C & i450C ADVANCED. CHOOSE LINCOLN FOR EXCELLENT AND EFFICIENT...

Open the catalog to page 2

FULLY SYNERGIC 7" TFT COLOR SCREEN MANUAL MIG SIMPLE USER INTERFACE SPECIFICATIONS Product Item Number Protection Class Product COOL ARC® 26 Item Number Protection Class

Open the catalog to page 3

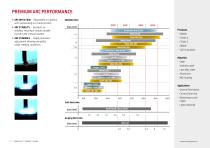

PREMIUM ARC PERFORMANCE RC INITIATION – Repeatable arc ignition A with outstanding arc characteristics. A RC STABILITY – Excellent arc stability, ensuring a smooth droplet transfer with reduced spatter. A RC DYNAMICS – Rapid parameter adjustment allowing variability under welding conditions. Processes • GMAW • FCAW-G • FCAW-S • SMAW • CAG (only i450C) Aluminium 4043 & 5356 Metal Cored Steel: SG2, SG3 Metal Cored Steel: SG2, SG3 Steel: SG2, SG3 Aluminium: 4043 & 5356 Metal Cored Rutile Stainless Steel: LNM Steel: SG2, SG3 Materials • Steel • Stainless steel • ow alloy steel L • ...

Open the catalog to page 4

CLOCK & CALENDAR Weld quality data can also be monitored, logged and recorded using a USB NEW ERGONOMIC HANDLE for safe movement of the machine and an effortless grip, even when wearing gloves CABLE MANAGEMENT SYSTEM (option) For easy transportation of the whole welding system, (cables, guns, etc.) NEW ENCODERS for more precise adjustment SPEAKER Additional audio signals when adjusting the encoders and when any improper operation is selected. Training, advertising and other video displays now also include sound POWERTEC® I COMPACT RANGE

Open the catalog to page 5

FUNCTIONALITIES & ERGONOMICS ERGONOMIC DESIGN COOL ARC® 26 as option (only for i380C & i450C) Tilting gas bottle tray for ease of loading height for easy-to-view settings Easy maneuverability and small footprint Convenient top-mounted expendable parts compartment Tools storage LED lighting inside feeder chamber 7'' color TFT screen Simple navigation also when using welding gloves Rubber bumpers protecting feet (as standard for i380C & i450C) 4 lifting eyes for easy hook-in and safe transportation 6 POWERTEC® I COMPACT RANGE Inspection window Large wheels to easily and effortlessly overcome...

Open the catalog to page 6

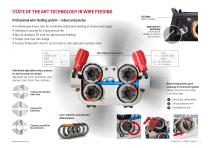

STATE OF THE ART TECHNOLOGY IN WIRE FEEDING LED lights: better visibility Professional wire feeding system – robust and precise individually driven rolls for extremely stable wire feeding of various wire types 4 luminum housing for a long service life A roll diameter (37 mm) for optimal wire feeding Big Simple, tool-free roll change Factory-fitted with rolls for 1,0 mm and 1,2 mm steel and stainless steel Steel Stainless steel Braze Flux cored Aluminium Optimized wire positioning: improved arc stability & reduced gun vibration Wire feeder pressure set-up Steel Stainless steel Braze 2,5 ÷...

Open the catalog to page 7

BUILT FOR DEMANDING INDUSTRIAL CONDITIONS High duty cycle 420A/100% (i450C) igh production efficiency H Easy maintenance and servicing Easy access to internal components Software update via laptop or USB (Advanced version) Inverter engine technology – ECO Friendly ower energy consumption L utomatic power-saving modes (standby/shutdown function) A Lincoln Electric Industrial design – ready to use anywhere afety class IP23, potted PCBs S and no structural plastics Year full parts and labour warranty 3 Parts & Labour Year warranty Cooling tunnel design POWERTEC® I COMPACT RANGE

Open the catalog to page 8

INNOVATIVE, INTUITIVE USER INTERFACE – REDUCED TIME FOR TRAINING Simple navigation also when using welding gloves Innovative and easy communication wo controls, one button for easy navigation T language for key commands Icon asy process and settings selection E RCFX™ – joint visualization A ork point in material thickness (mm) / WFS / A W ocking function / Limits / Memories / Jobs L Interface available in languages: English, German, French, Polish, Finnish, Spanish, Italian, Russian, Dutch, Romanian, Slovakian, Hungarian, Czech, Turkish, Portuguese More functions & features AUTO-SETTINGS...

Open the catalog to page 9

STANDARD USER INTERFACE – BASIC SETTINGS Welding Process & Shielding Gas Selection elding characteristics optimized in terms of welding W process (GMAW/FCAW or SMAW) selection and shielding gas type for the best dynamics and minimal spatter imple and quick selection by pressing the button S EDs showing the selected process L Easy access to the most commonly used welding parameters: rc dynamics (inductance effect - from soft to hard) A orch trigger mode 2-step / 4-step T ire Feed Speed Run-in function W Welding flowchart for easiest setting of all welding parameters 10 POWERTEC® I COMPACT...

Open the catalog to page 10

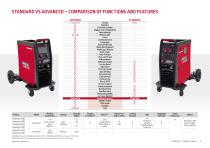

STANDARD VS ADVANCED – COMPARISON OF FUNCTIONS AND FEATURES ADVANCED (i450C) Product Powertec i450C Powertec i380C Powertec i320C Powertec i250C Powertec i320C Powertec i250C Welding parameters 7 TFT colour screen with ARCFX™ Auto / Manual LEDs meters Memories / JOBs / Limits Locking function Joint visualization Work point in A/mm Software update Welding Data Colection UI type Speakers Clock and calendar Display view configuration Auto settings Memory Jobs Limits Locking function Languages USB connectivity Media files (Support) Weld Logs / History Quick Triger Push-Pull gun Cross-switch...

Open the catalog to page 11

New COOL ARC® 26 cooler fully controlled by power source More functions and features Cooler Menu is available when cooler is connected Coolant filter keeps coolant clean (Back side view) Built-in handle for easy transportation LED lights inside reservoir for clearer visibility of the coolant level Settings: 3 Modes of operation available: Flow sensor inside for gun protection Filling Procedure step by step detail filling instruction Cooler fully controlled by power source: AUTO/ON/OFF for better energy savings and extended service life Simple Connection and Easy Installation POWERTEC® I...

Open the catalog to page 12All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

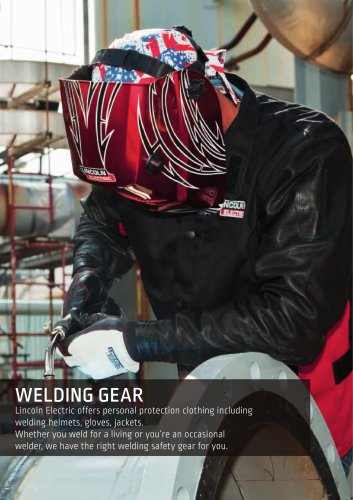

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

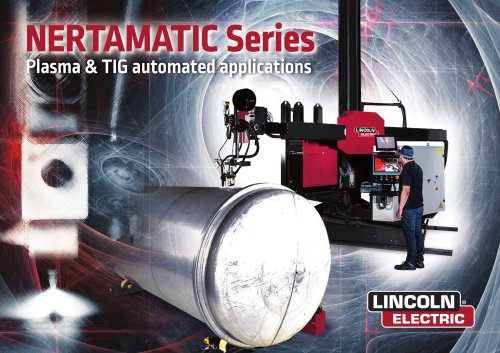

NERTAJET BEVEL HPi

2 Pages

-

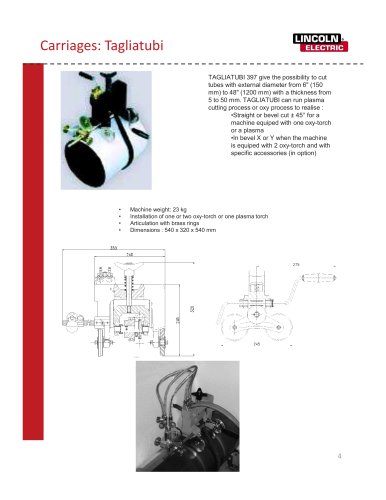

Carriages: Tagliatubi

1 Pages

-

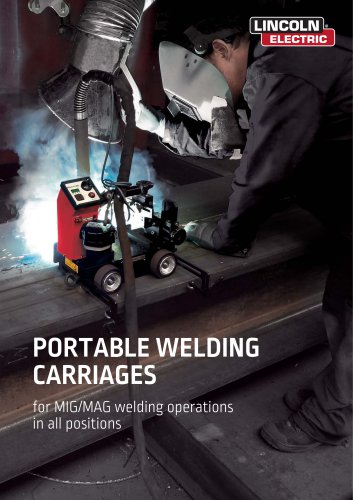

PORTABLE WELDING CARRIAGES

4 Pages

-

ROTAMATIC Roller beds range

4 Pages

-

STICK WELDING RANGE

16 Pages