Catalog excerpts

PLASMA CUTTING RANGE INVERTEC® PC-210 ⋅ TOMAHAWK® 1025 ⋅ TOMAHAWK®

Open the catalog to page 1

CHOOSE LINCOLN FOR CLEAN, EFFICIENT AND COST-EFFECTIVE PLASMA CUTTING Cut through any conductive material in seconds. Choose a model just right for your typical material thickness. Our plasma cutters are as good as the best in Class, with prices far below competitors (the machine as well as the consumable parts). INVERTEC® PC-210 - portable, flexible cutting power up to 10 mm, powered from a standard 230V input supply, ideal for work on site. TOMAHAWK® 1025&1538 - high performance plasma cutting machines, built to handle harsh environmental conditions, suitable for operation on site with a...

Open the catalog to page 2

PC-210 INVERTEC® PC-210 • Flexible: only 230 V input required. • High performance: innovative advanced electrode and nozzle design. • Robust: long life compressor. • Portable: only 18,5 kg, small and compact. • Different materials: mild steel, stainless steel, aluminium and many more. • Concentrated plasma stream: less heat input, less distortion. • Internal compressor or external. Plate thickness (mm) PC-210external compressed air Processes • Plasma cutting Applications On site maintenance Service tasks Small construction sites General installations Air ducting installation (HVAC)...

Open the catalog to page 3

Processes • Plasma cutting [all] • Plasma gouging • Grid Mode TOMAHAWK® 1025 & 1538 Type of Gas • Air compressed • Nitrogen Applications On site maintenance Service tasks Small construction sites General installations Air ducting installation [HVAC) Demolition work Rental Motor generator compatibility MOTOR GENERATOR COMPATIBILITY: • minimum power 9,2kW [TH1025], 18kW [TH1538] • AC waveform peak voltage below 700V. • RMS voltage of the AC waveform is always equal to 400Vac ±15%. Starting: innovative advanced arc starting without HF. Performance: innovative advanced electrode and nozzle...

Open the catalog to page 4

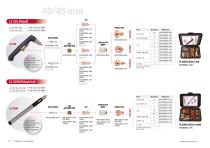

CUTTING CIRCLES (max diam. 820mm) W0300699A

Open the catalog to page 5

MODERN TORCH TECHNOLOGY LC65 and LC105 ALSO AVAILABLE: EXTENDED REACH CONSUMABLES HELPFUL FOR CONFINED SPACES – the new torches with longer life time (running cooler). More cutting thickness, higher speed, standard and grid cutting. O HF N Small electrode diameter Primary and secondary flow Concentrated plasma life electrodes and nozzles Torch Connection –central connector, 9-pin For connection equipment /torch the Tomahawk are provided by CENTRAL CONNECTOR HIGHER TRAVEL SPEED AND LONGER LIFE TIME CONSUMABLES CONTACT Maximum flexibility and visibility of the plasma stream. Allowing you to...

Open the catalog to page 7

GOUGING WITH TOMAHAWK® 1025 & 1538 Plasma gouging was developed as a tool for weld removal and weld preparation. Back-gouging was used to remove metal from the reverse side of arc-welded joints to eliminate defects and improve strength. Weld defects such as cracks, porosity, and lack of fusion could be gouged out using a plasma torch and then repaired with a new, sound weld. Gouging application with manual plasma torch LC65 Gouging application with manual plasma torch LC105 Material : Mild Steel Suggested speed : 90 cm/min Suggested torch inclination: 55° from vertical Suggested Air...

Open the catalog to page 8

W03X0893-25A (contact, stand off, shielded & gouging) W03X0893-53A (extended) www.lincolnelectric.eu PLASMA CUTTING RANGE

Open the catalog to page 9

ELECTRODE LC 105 W03X0893-60A [shielded & gouging] Air cooled 280 l/min@5,5 bar 100A@60% 40mm mild steel 45mm severance ELECTRODE GAS DISTRIBUTOR TIP SHIELD CUP BODY SHIELD CAP o LU o _l LU Air cooled 280 l/min@5,5bar 100A@60% 40mm mild steel 45mm severance PLASMA CUTTING RANGE

Open the catalog to page 10

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements. Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.eu for any updated information. CUSTOMER ASSISTANCE POLICY The business of The Lincoln Electric...

Open the catalog to page 12All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

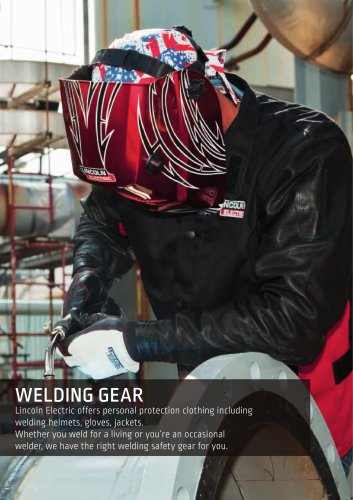

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

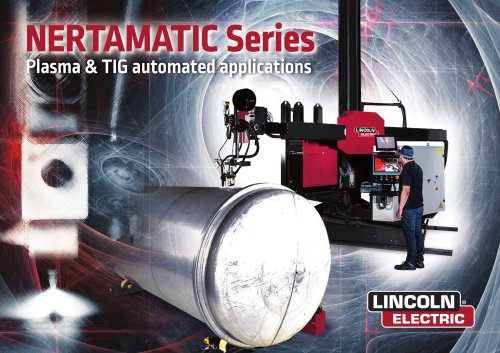

NERTAJET BEVEL HPi

2 Pages

-

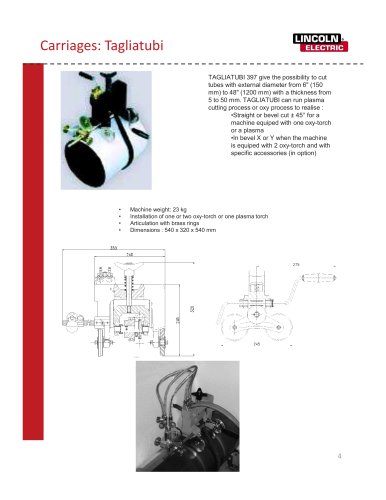

Carriages: Tagliatubi

1 Pages

-

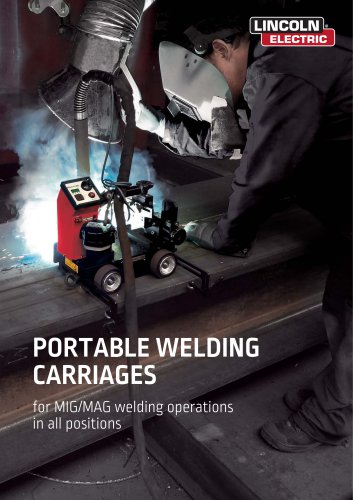

PORTABLE WELDING CARRIAGES

4 Pages

-

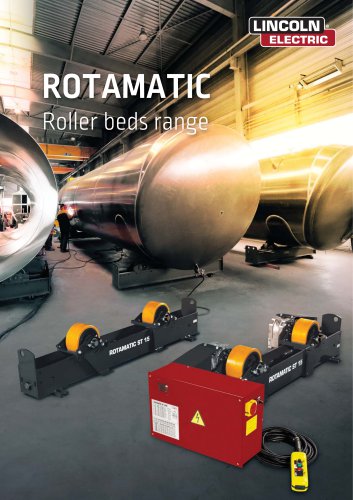

ROTAMATIC Roller beds range

4 Pages

-

STICK WELDING RANGE

16 Pages