Catalog excerpts

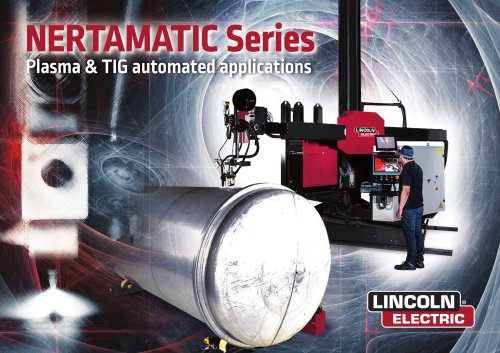

NERTAMATIC Series Plasma & TIG automated applications

Open the catalog to page 1

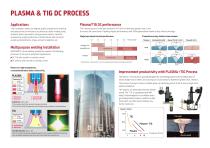

PLASMA & TIG DC PROCESS Applications The Plasma process is the ideal extension of TIG for thicknesses greater than 3 mm. It ensures the same level of quality, higher performances and 100% penetration thanks to Key-Hole technology. This installation meets the highest quality standards for welding and productivity for industries as diverse as boiler-making using stainless steels, aeronautics using precious metals, chemical engineering, energy production, transformation and transport as well as prefabrication of gas and petrol pipelines etc. Single pass plasma Key hole performance 0,5...

Open the catalog to page 2

This installation meets the highest quality standards for aluminium applications, industries as diverse as storage tanks, food industry, transport, structures and ship building. Aluminium TIG performance Single pass TIG performance Multipurpose welding installation NERTAMATIC series welding installation enables with an AC module option to allow AC TIG variable polarity. Maximum thickness which can be welded, flat* with butt-jointed surfaces, in one pass with 100 % penetration: 2.5 single pass single pass multi pass * Perfomance is reduced for vertical welding (2G & 3G) limits according...

Open the catalog to page 3

BOILER MAKER typical solutions Manufacture of all types of product, transforming the metal sheet, performing longitudinal and circular welding for the petrochemical, agriculture/food processing, aeronautical industries etc. Longitudinal welding on seamer bench up to 10 mm thickness Circular welding with column and boom on rotator or positioner INTER SEAMER Up to 7200 mm welding length* EXTER SEAMER Up to 4200 mm welding length* Typical boiler maker work shop EX-INTER SEAMER Up to 6200 mm welding length* * Other dimensions on request Elliptical welding with column and boom on rotator

Open the catalog to page 4

VERTICAL TANK Prefabrication of pipe work is carried out upstream of installation. It enables sub-assemblies to be prepared and welded from basic components (pipes, flanges, elbows etc...) in the workshop. 2000-343 Use of plasma or TIG processes for vertical welding of stainless steel, noble metals, steels or aluminium. Manufacture of storage equipment for agriculture/food processing, petrochemical industries. It is used in a variety of industrial sectors: ■ shipbuilding and off -shore platforms ■ refineries and power stations ■ chemical and agriculture/ food processing plants ■ gas...

Open the catalog to page 5

Multipurpose installation able to perform Plasma or TIG, DC or pulsed, TIG AC variable polarity. Management of all welding functions such as: GAS MANAGEMENT All gases are controlled by the welding installation with flowmeter excepted the plasma gas which is driven by a digital valve in order to fine tune the keyhole process. WIRE FEED It is often necessary to feed the melting bath with metal during the operation in order to prevent the seam from showing hollows, to supply soft steels with deoxidizing elements, for succesive seams. HOT WIRE Productivity improvement by increasing the...

Open the catalog to page 6

PILOT ADVANCE WELDING ACTIVITY UNDER CONTROL Two different systems to manage the Plasma/TIG process are available. According the typology of machine, the number of parameters to control, the monitoring and the traceability requirements. PILOT ADVANCE Clear display of welding cycle and related parameters Graphic display of the machine and welding head ■ Stand alone process Typology for retrofit or ■ Simple machine with 1 analog axis ■ Machine management including process with unlimited digital axis ■ LCD display + quick access buttons ■ 19" user friendly touch screen ■ Unlimited programs A...

Open the catalog to page 7

Lincoln Electric is a responsive manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility of the customer. Many variables beyond the control of Lincoln Electric aff ect the results obtained in applying these types of fabrication methods and service requirements. Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectriceurope.com for any updated information. CUSTOMER ASSISTANCE POLICY The business of Lincoln...

Open the catalog to page 8All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

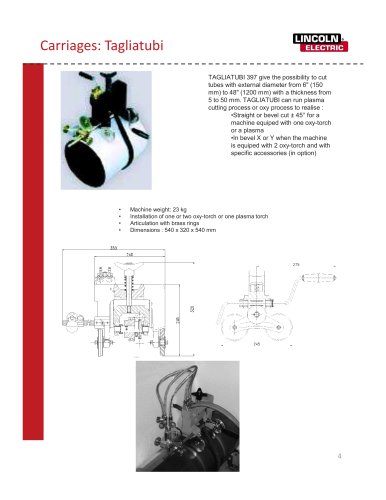

Carriages: Tagliatubi

1 Pages

-

PORTABLE WELDING CARRIAGES

4 Pages

-

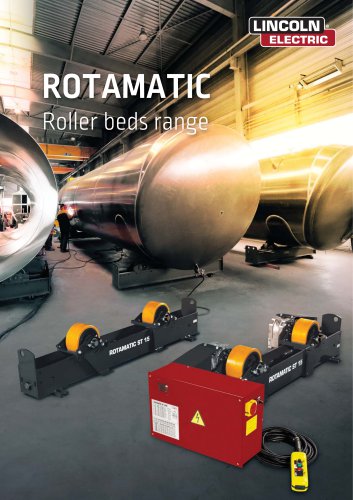

ROTAMATIC Roller beds range

4 Pages

-

STICK WELDING RANGE

16 Pages