Catalog excerpts

FASTER WELDING ON FIELD WITH INNERSHIELD®

Open the catalog to page 1

HIGH PRODUCTIVITY SOLUTION INNERSHIELD® wires A COMPLETE PORTFOLIO FOR SEVERAL APPLICATIONS TOTAL SOLUTION TO WORK WITH INNERSHIELD® INNERSHIELD® GUNS SELF-POWERED CARRIAGES FOR MECHANIZED ALL POSITIONAL WELDING COMPLETE RANGE OF PPE FOR YOUR PROTECTION EQUIPMENT PACKAGES TO SATISFY YOUR REQUIREMENTS DIY CROSSLINC® TECHNOLOGY TO REGULATE WELDING PARAMETERS FROM THE WIRE FEEDER OUTDOOR OUTDOOR/ INDOOR FASTER WELDING ON FIELD WITH INNERSHIELD®

Open the catalog to page 2

LINCOLN ELECTRIC INVENTED THE FIRST SELF-SHIELDED FLUX-CORED WIRE 1. Green Rod or Butt Seam Lap Seam 3. Outer Steel Sheath Inner Flux Core INNERSHIELD® THE RIGHT SOLUTION FOR OUTDOOR WELDING, ADVANTAGES OVER OTHER COMMON PROCESSES TABLE OF CONTENTS THE RIGHT SOLUTION FOR OUTDOOR WELDING THE PROCESS SAFE AND RELIABLE PROCESS INNERSHIELD® RANGE SELECTION CRITERIA EQUIPMENT AND ACCESSORIES INDUSTRIAL APPLICATIONS FASTER WELDING ON FIELD WITH INNERSHIELD®

Open the catalog to page 3

INNERSHIELD® – THE RIGHT SOLUTION FOR OUTDOOR WELDING OVER STICK WELDING PROCESS Welding cost (€ / kg)* Welding cost (€ / kg) Duty cycle Duty cycle ** Fillet weld a5 mm size in PB position INNERSHIELD® ADVANTAGES OVER STICK WELDING PROCESS • Continuous process • Longer Arc time and increased operating factor • Higher deposition rates • Increased productivity • ewer stops and starts = fewer defects F COST SAVING EXAMPLE BETWEEN INNERSHIELD® AND SMAW PROCESSES APPLICATION BASE MATERIAL: S355 Thickness : 10 mm Joint type : A5 FW in PB (2F) Welding modality manual Current Amperage 140-180...

Open the catalog to page 4

FOR MORE PRODUCTIVITY, MOVE FROM SMAW TO FCAW. CHOOSE INNERSHIELD® IF... THE USE OF GAS BOTTLES TYPICAL ISSUES USING GAS • supply of right gas mixture • regular delivery of bottles on field • safe gas bottle handling • protected store • ontinue maintenance of hoses and gas pressure regulators c (cost/time lost, gas leakage, dedicated person in charge of) THE WIND REPRESENTS AN ISSUE INNERSHIELD® ALLOWS: • elding under wind speeds up to 50 km/h W and favourable operating characteristics without losing mechanical properties • ess defects such as porosity and wormholes L • o need to invest...

Open the catalog to page 5

INNERSHIELD® – THE PROCESS Lincoln Electric Company invented the FCAW-S process in 1958, with the Innershield® line of electrodes (Innershield® wires). Innershield® is an important process for steel fabrication in many industries, particularly when done outdoors. It is a primary welding process for structural steel building erection. TYPICAL APPLICATIONS • Steel Structure • Offshore • Shipbuilding • Field Maintenance • Pipelines • Heavy plate fabrication • Sheet metal • General fabrication • Rail welding • Home work – DIY TYPICALLY MADE IN LARGE DIAMETERS • from 1,6 to 3,0 mm • ome in...

Open the catalog to page 6

QUALITY CONTROL Innershield® is a process widely used worldwide in a great variety of applications. Innershield® wires are object of strict quality control in production to grant consistent performances. Innershield® wires are approved by third parties such as ABS, DNV, LRS (see product data sheet for better reference). Some Innershield® products are used for building construction in the seismically active regions of the US, where the stringent requirements of AWS D1.1 Structural Welding Code-Steel, and the D1.8 Seismic Welding Supplement apply. Product: Innershield® NR®-440Ni2...

Open the catalog to page 7

MAIN PRODUCTS Mild steel – all position welding capability Innershield® NR®-211-MP • ersatile welding capability on V a variety of base materials • igh operator appeal and good bead appearance H • asy slag removal E • ast freezing characteristics accommodate poor fit-up F • Restricted to 12 mm plate thickness Applications • heet or thin gauge metal S • alvanized sheet metal G • obotic/hard automation R • eneral fabrication G Mechanical Properties RM Elongation (%) 610 22 Applications • General & Seismic structural steel erection and fabrication • Ship and barge fabrication • ertical up...

Open the catalog to page 8

Low alloy steel – flat and horizontal welding capability Applications • illet and lap welds F • orizontal and square edge H butt welds, such as column-tocolumn structural connections • eep groove welds D • tructural fabrication S • eathering steels W • esigned for improved handling of poor fit-up D on heavy wall tubes and gaps up to 9,5 mm with 6,4 mm offset • Fast freezing slag with excellent wash-in • Root bead capability without back-up bars Specifications Classifications Chemistry Mechanical Properties Approvals AWS A5,36 EN ISO 17632-B C Mn Si S Ni RP0,2 RM Elongation (%) Impact ISO-V...

Open the catalog to page 9

INNERSHIELD® FOR SPECIAL APPLICATIONS: OFF-SHORE, RAIL, PIPELINE a RAIL TRACK Innershield® NS-3M • ersatile welding capability on a variety of base materials V • igh operator appeal and good bead appearance H • asy slag removal E • ast freezing characteristics help accommodate poor fit-up F Mechanical Properties RM Elongation (%) 580-620 25-28 Innershield® NR®-440Ni2 • esigned help provide provide optimal weldability in narrow TKY joints and poor fit up conditions D • xpect fast travel speeds and a flat bead face when using E vertical-up or vertical-down welding techniques • ow...

Open the catalog to page 10

INNERSHIELD® SELECTION CRITERIA SELECTION BASED ON MECHANICAL PROPERTIES OF STRUCTURAL STEEL Innershield® NR®-233 Innershield® NR®-203Ni* Innershield® NR®-232 Innershield® NR®-232-H Innershield® NR®-305 Innershield® NR®-311Ni * Suitable for weathering steel according to AWS D1,1 & D1,5 SELECTION BASED ON WELDING POSITION: Product Innershield® NR®-233 Innershield® NR®-203Ni Innershield® NR®-440Ni2 Innershield® NR®-555 Innershield® NR®-211-MP Innershield® NR®-311Ni* Pipeliner® 208-XP Innershield® NR -232 & 232-H Innershield® NR®-305* Innershield® NS-3M Welding position All except vertical...

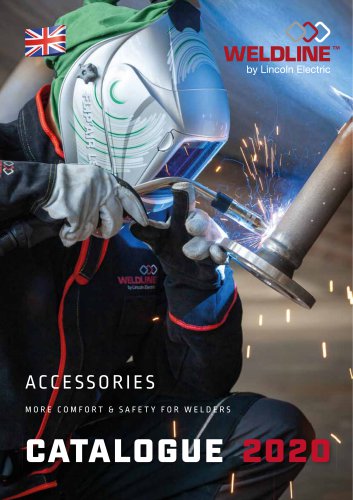

Open the catalog to page 11All Lincoln Electric Deutschland catalogs and technical brochures

-

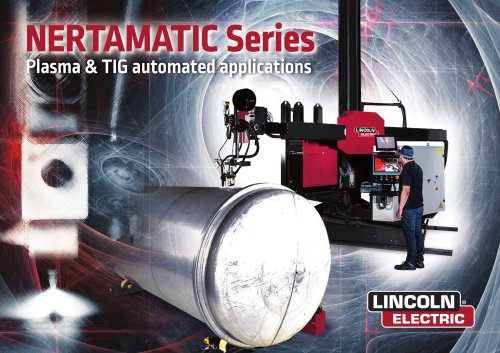

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

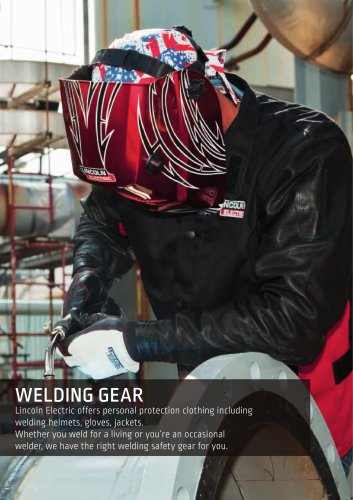

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

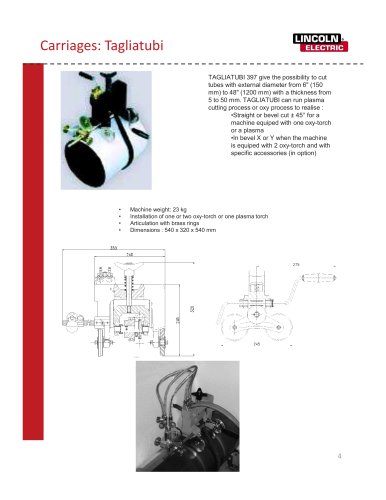

Carriages: Tagliatubi

1 Pages

-

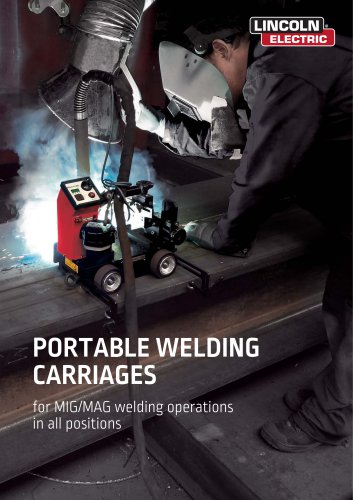

PORTABLE WELDING CARRIAGES

4 Pages

-

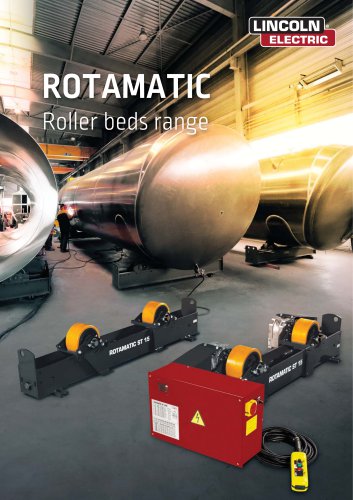

ROTAMATIC Roller beds range

4 Pages

-

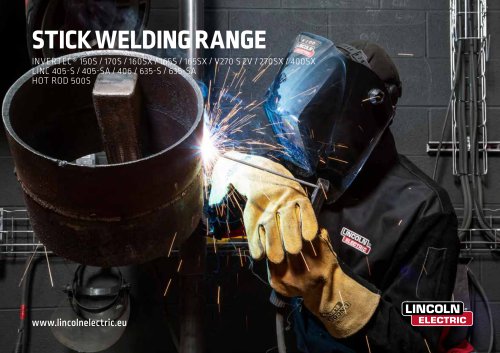

STICK WELDING RANGE

16 Pages