Catalog excerpts

AUTOMATIC WELDING & CUTTING

Open the catalog to page 1

"Automation" is an excellent opportunity for companies looking for continuous Improvement and performances. For Lincoln Electric the automation of welding and cutting processes is not new, but rather a source of innovation that we want to share with our customers. We invest heavily in the development of intelligent welding and cutting technology solutions to combine the quality and performance you want. Automation in general brings important changes in the way you organize your workshops. It is for this reason that the pooling of our expertise in the search for the most suitable solution is...

Open the catalog to page 2

SUMMARY TOTAL AUTOMATIC WELDING AND CUTTING SOLUTIONS INDUSTRY SEGMENTS CUTTING SYSTEMS CUTTING PROCESSES PRESENTATION . . . . . . . . . . . . . 13 FLEXCUT & NERTAJET HPi RANGE . . . . . . . . . . . . . . . . 15 - FLEXCUT 125 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 - LEXCUT 200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 F - NERTAJET HPi2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 - NERTAJET HPi . . . . . . . . . . . . . . ....

Open the catalog to page 3

TOTAL AUTOMATIC WELDING AND CUTTING SOLUTIONS ENVIRONMENT AND PROTECTION AUTOMATIC WELDING PROCESSES TOTAL SOLUTIONS FOR AUTOMATION AUTOMATIC CUTTING TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 4

Lincoln Electric offers a large choice of cutting and welding solutions for many segments and diverse industries. Automation is the solution to: IMPROVE QUALITY INCREASE THROUGHPUT IMPROVE WORKER SAFETY REDUCE COSTS ADDRESS SHORTAGE OF LABOUR TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 5

Chemical or food processing, pressure vessels, tanks, general industries Clamping bench Plasma & Oxyfuel cutting system with bevelling unit Column & boom Handling 4 TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 6

Transportation, automotive, heavy fabrication Cutting system Plasma High Precision Column & boom Beam welder TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 7

Pipe production, pipeline Internal boom TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 8

Process piping, offshore, pipe mill Side beam Column & boom Plasma cutting system with tube cutting Orbital welding www.lincolnelectriceurope.com TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 9

Cutting system High Precision with drilling unit Beam welder & Clamping bench 8 TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 10

Power generation, energy Plasma & oxyfuel cutting system Orbital welding Column & boom Growing line Self aligning roller beds www.lincolnelectriceurope.com TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 11

Plasma & Oxyfuel cutting system Portable tractors SAW & MIG/MAG 10 TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING Beam welder

Open the catalog to page 12

Distribution, sub-contractor, locksmiths Compact cutting machines Robotic cell TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 13

CUTTING SYSTEMS

Open the catalog to page 14

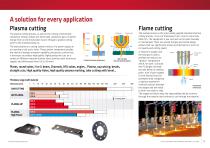

A solution for every application Plasma cutting The plasma cutting process, as used in the cutting of electrically conductive metals, utilizes this electrically conductive gas to transfer energy from an electrical power source through a plasma cutting torch to the material being cut. The basic plasma arc cutting system consists of a power supply, an arc starting circuit and a torch. These system components provide the electrical energy, ionization capability and process control that is necessary to produce high quality, highly productive cuts on a variety of different materials (carbon...

Open the catalog to page 15

TOTAL SOLUTION PROVIDER ISO 9013: Main cutting quality criteria Advance cutting process and improved data base parameters Tolerances of perpendicularity or angularity A machine equipped with a numerical control with high performance Various features can be evaluated to understand the cutting quality. EN standard ISO 9013 retains mainly three: ● eometric accuracy, G ● oughness surface, R ● ngle / concentricity. A This last criteria determines, based on the thickness, the perpendicularity tolerance in five classifications (ranges 1 to 5). Technician with cutting expertise Table & fume...

Open the catalog to page 16

Heavy power High precision Plasma thickness range multi material Thickness (mm) NERTAJET HPI Heavy Power www.lincolnelectriceurope.com Piercing limit * different depending the material TOTAL SOLUTIONS FOR AUTOMATIC WELDING & CUTTING

Open the catalog to page 17

FLEXCUT® 125 125A Powerful, 100% Air Plasma Make the cut in the big game Low Operating Costs Keeping costs under control is important to any efficient plasma cutting operation. The FlexCut® 125 ensures up to six times longer consumable life and maintains faster cut speeds - both of which deliver higher productivity over less time. The completed cut is virtually dross-free, which means less secondary processing. B©©est Cutting and Marking Performance The FlexCut® 125 is designed to deliver on all fronts as the only machine in it’s class that allows you to plasma mark. Whether you are...

Open the catalog to page 18

FLEXCUT® 200 Mechanized Dual Gas Plasma Cutting System Premium Cut Performance: 2 00A, 100% Duty Cycle maximiezq production efficiency. O perates using air for daily use and intensive production. ● ossibility to cut with O2 or N2 time to time for higher P quality. ● ● Easy of Use: F ull color grpahic display with one-knob selection process. R eliable arc starting with CleanStrike® Technologie. ● emovable torch head for easy assembly of consumables. R ● ● Low Operating Costs: L iquid-cooled plasma torch for more consistent cuts and longer-lasting consumable life. ● ess dross reduces need for...

Open the catalog to page 19

NERTAJET HPi2 150A or 300A High Precision Plasma Cutting System Quality cutting beyond the high precision market standard Quality: Operating costs: This cutting tool is used to obtain the following: ● imensional and geometrical accuracy of the pieces cut on a D wide range of materials. ● uality of the surface of the cut faces (roughness far below Q than that of a laser). ● cut angle (range 2 to 4 in accordance with ISO 9013). A ● oles with a remarkable straightness on carbon steel with H HOLE MASTER. ● uts with no adhering slag. C ● uality maintained thanks to the optimized life time and...

Open the catalog to page 20All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

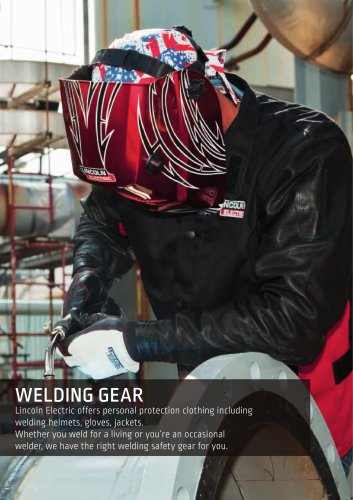

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

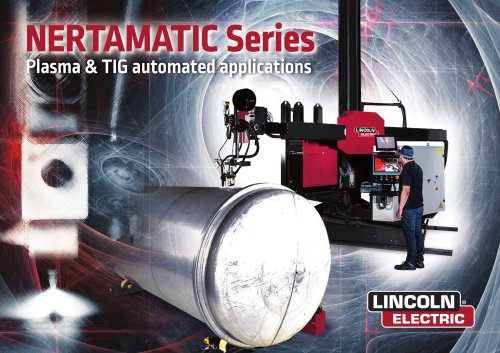

NERTAJET BEVEL HPi

2 Pages

-

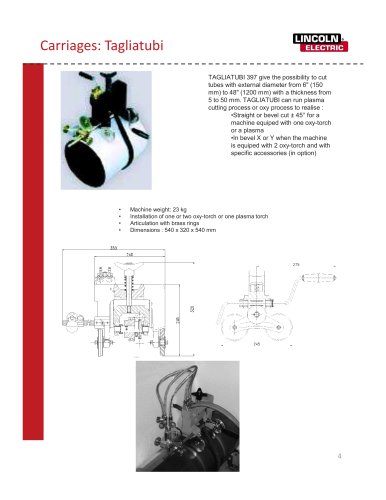

Carriages: Tagliatubi

1 Pages

-

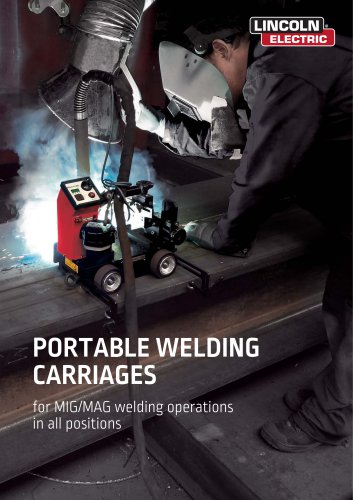

PORTABLE WELDING CARRIAGES

4 Pages

-

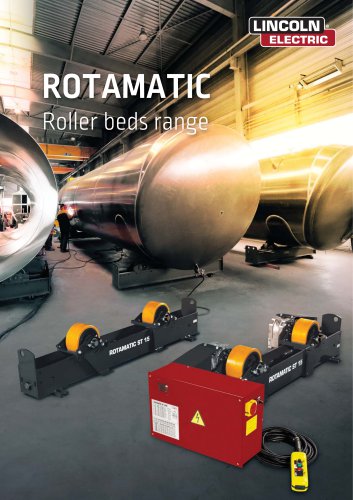

ROTAMATIC Roller beds range

4 Pages

-

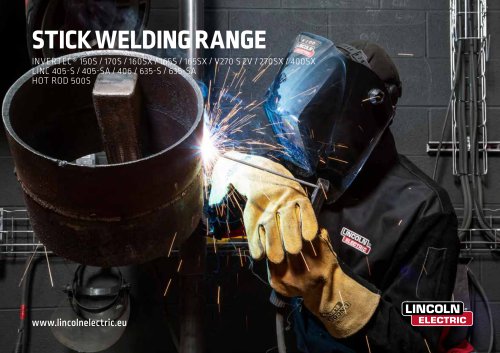

STICK WELDING RANGE

16 Pages