Catalog excerpts

LINCOLN ELECTRIC WEBSHOP MORE POSSIBILITIES FROM 1 HAND As the world’s technological leader in welding and cutting, Lincoln Electric expands the limits of what is possible every day. To make sure you as our customer manage everything you need whenever and wherever you need it, we have created a new e-commerce solution – placing your orders has never been so easy. Due to an intuitive navigation, our web shop enables you to buy products quicker than ever: 24/7, all year round. Try it on community.lincolnelectric.com

Open the catalog to page 2

CONTENTS Custom design General data/Indoor pollution targets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 Occupational exposure limit values/Atmospheric discharge targets FUME EXTRACTION TORCHES . . . . . . . . . . . . . . . . . . . . . . . . 83 - 88 ERGONOMIC BOOMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89 - 92 TURBINES AND CENTRAL UNITS . ....

Open the catalog to page 3

GENERAL Fume and dust extraction systems are designed on the basis of several criteria. Each individual system is devised to suit the process and the type and characteristics of the fumes. In general, industrial fumes are discharged outside the building in order to comply with the gas exposure values set by CARSAT and INRS (in France) and are also generally filtered to comply with the specifications issued by DREAL in respect of the environment. Machinery for ventilation and for the capture of fumes from welding, cutting, grinding and sanding must take account of two criteria: 1. Pollution...

Open the catalog to page 4

DATA OCCUPATIONAL EXPOSURE LIMIT VALUES Concentration levels in the working atmosphere and the respiratory tracts of operators that may not be exceeded or occupational exposure limit values (OELV) have been established by the ministry for labour, in order to protect workers’ health (some values are also recommended by the national employees’ healthcare insurance fund: CNAMTS). Occupational exposure limit values are the concentration limits that may never be exceeded in the air inhaled by workers. They are derived from the current scientific data available to specialists about the toxicity...

Open the catalog to page 5

GENERAL INFORMATION General The pollutants generated by each welding or cutting process are different due to their: ◆ type, ◆ concentration, ◆ and also direction. The capture system must therefore be adapted on the basis of these different criteria. Welding operations. Regardless of the process used, including braze welding, the fumes are hot and therefore naturally rise in the air. Fumes can be captured at source with a fume extraction torch (high-vacuum system) or from the work surface with extraction arms or down-draft tables (low-vacuum system). As a result, fumes are carried away above...

Open the catalog to page 6

Digifilter (page 56) Extraction panel (page 14) Extraction arm (page 17 - 34) Work table (page 7) Extraction hood (page 15) Down-draft table (page 8) Down-draft work table (page 7) Heavy-duty down-draft table (page 9) Down-draft cutting table (page 10) Example of low-vacuum equipment: PROJECTS ACCORDING TO ATEX GAS AND DUST STANDARDS CAN BE CARRIED OUT ON REQUEST

Open the catalog to page 7

LOW-VACUUM PROCESS CONTENTS DOWN-DRAFT TABLES 1 BRAZE WELDING TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 2 BRAZE WELDING DOWN-DRAFT TABLE . . . . . . . . . . . . . . . . . . 7 3 DUO BRAZE WELDING DOWN-DRAFT TABLE . . . . . . . . . . 8 CONTROL BOXES 6 HEAVY-DUTY DOWN-DRAFT TABLE . . . . . . . . . . . . . . . . . . . . . . . 9 7 ESSENTIAL GRINDING DOWN-DRAFT TABLE . . . . . . . . . . 9 8 ESSENTIAL CUTTING DOWN-DRAFT TABLE . . . . . . . . . 10 9 ASMV DOWN-DRAFT TABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 MOBILE...

Open the catalog to page 8

DOWN-DRAFT TABLES Our range of down-draft tables contain different versions to suit your application: Braze welding tables with no extraction. Ordering Description Table dedicated to training in welding and brazing. Bare welding table, 850 x 665 mm Work surface to select below: Combined grating and steel plate surface Combined grating and refractory brick surface Full refractory brick surface It is available in two dimensions: 850 x 665 mm. 1,100 x 665 mm. Three work surface configurations are possible: Bare welding table, 1,100 x 665 mm Work surface to select below: Combined grating and...

Open the catalog to page 9

DOWN-DRAFT TABLES Duo down-draft table for welding and brazing The Duo down-draft table for welding and brazing captures fumes from two workstations and all welding processes through a front extraction panel. The work surface is to be selected based on the need: Work surface with grating for welding (supplied as standard). Option: Work surface in refractory brick and wooden deburring block for brazing. T wo work surfaces with area (880 x 550 mm). Height 870 mm. P ollutants are captured by the extraction panel with a removable front located opposite each work surface. P ermissible load per...

Open the catalog to page 10

DOWN-DRAFT TABLES Heavy-duty down-draft table for welding and grinding The down-draft table captures fumes from all welding processes and grinding operations with heavy parts up to 500 kg. Permissible load (kg/m²) Hinged lateral panels, 800 mm high. Work surface height: 920 mm. Collecting hopper under the work surface with dust drum. Two work surface configurations with 25 mm thick steel are possible: - Standard work surface, - Special work surface for the use of Demmeler clamps. Mechanically welded structure. Extraction through the work surface and front panel. Part number Table, 1,200 x...

Open the catalog to page 11

DOWN-DRAFT TABLES Essential down-draft table for cutting The all-process cutting table captures non-explosive metal dust and can be complemented with a grinding kit. G rinding kit made up of: Metal grating. 2 lateral panels, 500 mm high. 1 front panel, 500 mm high. Permissible load: 30 mm thick steel plate. Cutting surface height: 700 or 900 mm. B ent plate construction, bolted together. Cutting surface with metal plates (6 x 60 mm) to support workpieces. Heavy particle recovery drawers. Filter with cleaning function to add Part number Essential cutting table, 1,000 x 500 mm Grinding kit,...

Open the catalog to page 12All Lincoln Electric Deutschland catalogs and technical brochures

-

PROCESS PIPING 4.0

15 Pages

-

HYPERFILL®

6 Pages

-

TIG DC RANGE

12 Pages

-

POWERTEC®-i S RANGE

20 Pages

-

LINCOLN 7016DR

4 Pages

-

FASTER WELDING ON FIELD

20 Pages

-

SUPRAMIG®

6 Pages

-

POWERTEC®-i COMPACT RANGE

16 Pages

-

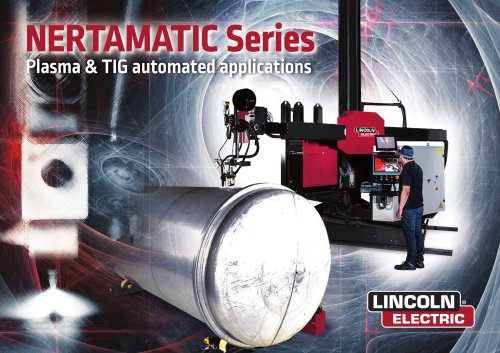

AUTOMATIC WELDING & CUTTING

92 Pages

-

Welding & Cutting EQUIPMENT 2021

136 Pages

-

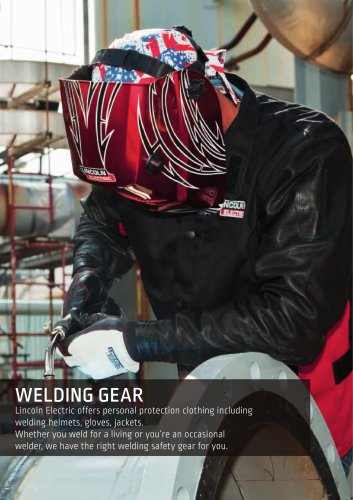

WELDING GEAR

5 Pages

-

4C® LENS TECHNOLOGY

2 Pages

-

WELD FUME CONTROL

9 Pages

-

Invertec® PC-210

1 Pages

-

NERTAJET BEVEL HPi

2 Pages

-

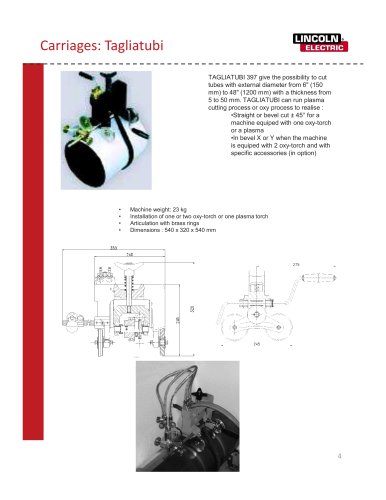

Carriages: Tagliatubi

1 Pages

-

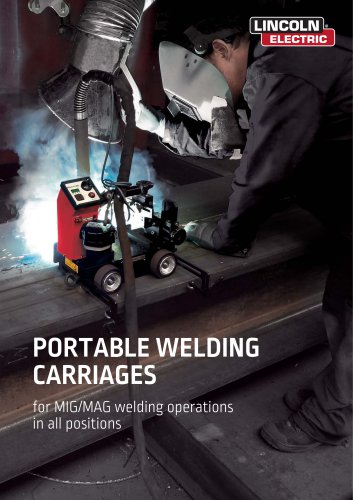

PORTABLE WELDING CARRIAGES

4 Pages

-

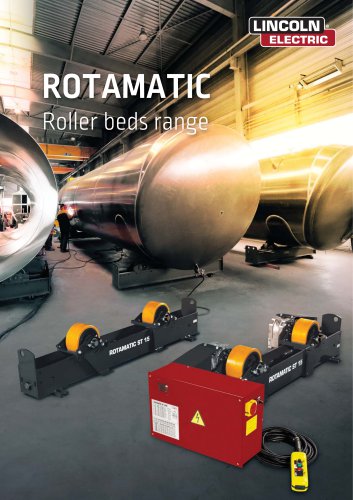

ROTAMATIC Roller beds range

4 Pages

-

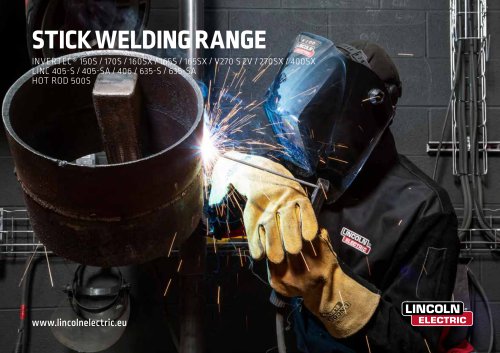

STICK WELDING RANGE

16 Pages