Catalog excerpts

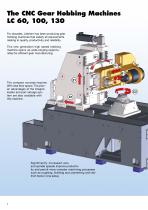

The CNC Gear Hobbing Machines LC 60 – 130

Open the catalog to page 1

The CNC Gear Hobbing Machines LC 60, 100, 130 For decades, Liebherr has been producing gear hobbing machines that satisfy all requirements relating to quality, productivity and reliability. This new generation high speed hobbing machine opens up wide-ranging opportunities for efficient gear manufacturing. A1 V1 B1 The compact concept requires 20% less floor space. The proven advantages of the integral loader and part storage system are also available with this machine. Significantly increased axis and spindle speeds improve productivity and permit more complex machining processes such as...

Open the catalog to page 2

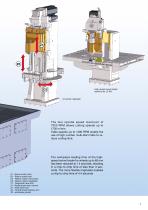

High-speed swivel loader (optional for LC 60) Universal ringloader The tool spindle speed maximum of 7000 RPM allows cutting speeds up to 1700 m/min. Table speeds up to 1400 RPM enable the use of high number multi-start hobs to reduce cutting time. A1 - Swivel motion tool B1 - Rotary motion tool C2 - Rotary motion work piece C3 - Rotary motion ringloader V1 - Tangential travel tool X1 - Radial travel main column Z1 - Axial travel tool Z4 - Vertical travel tailstock arm Z5 - workpiece pocket The workpiece loading time of the highspeed swivel loader for wheels up to 60 mm has been reduced to...

Open the catalog to page 3

Customer Expectations Intensive information exchange with our customers throughout the world and extensive practical experience with our existing generation of machines had a major impact in the development of this machine. For example - The new machine enclosure, an improved chip flow for the dry cutting process, and a very rigid deburring unit. Work area enclosure 4 Optimized chip removal Deburring unit

Open the catalog to page 4

Machine development focused on the following criteria: • Minimized set-up time • Ease in operation • Reduced complexity As a consequence, the quick-change gripper system, an automatic counterbearing for faster tool change and the 2-station ringloader are now standard features. High-speed 2-station swivel loader (LC 60) Automatic counterbearing

Open the catalog to page 5

Customer Benefits The development of this machine focused on high availability with minimum maintenance requirements. Maintenance tasks have been greatly reduced (e.g. by using a grease lubrication system for the guideways). Separate areas for the electric, hydraulic and pneumatic components are clearly identified and easily accessible. Hydraulic/Lubrication area

Open the catalog to page 6

Max. workpiece diameter Max. nominal module for steel Hob slide travel (axial) Table diameter Table speed Center distance hob/work table Hob head swivel angle Max. shift travel Max. hob diameter Max. hob length/max. toothed length Rapid traverse, axial Rapid traverse, radial Rapid traverse, tangential Rapid traverse, A-axis Hob spindle speed Drive power, hob spindle Weight of machine with tailstock column mm mm mm mm rpm min. mm max. mm degrees mm mm mm mm/min mm/min mm/min °/s rpm kW Approx. kg 1 Operator panel 2 Electrical cabinet 3 Chip conveyor 4 Chip cart 5 Maintenance area for...

Open the catalog to page 7

Liebherr-Verzahntechnik GmbH Werk Ettlingen Liebherr Gear Technology, Inc. Liebherr Machine Tools India Pvt. Ltd. Via Nazioni Unite 18 I-10093 Collegno TO 1465 Woodland Drive Saline, MI 48176-1259 USA 353/354, 4th Main, 9th Cross, 4th Phase Peenya Industrial Area Bangalore - 560 058, India Printed in Germany by Roth BK 07.11 Liebherr-Verzahntechnik GmbH Kaufbeurer Strasse 141, D-87437 Kempten +49 (0)831 786-0, Fax +49 (0)831 786-1279 www.liebherr.com, E-Mail: info.lvt@liebherr.com

Open the catalog to page 8All Liebherr Verzahntechnik catalogs and technical brochures

-

Process monitoring ARTIS

4 Pages

-

Chamfering of gearing

2 Pages

-

LVT-LC 2000-16000

6 Pages

-

LVT-LC 600-2000

4 Pages

-

LVT-LC 200-500

6 Pages

Archived catalogs

-

Reman Program

8 Pages

-

Genuine parts from Liebherr

16 Pages

-

The Liebherr Reman Program

16 Pages

-

The ChamferCut process

4 Pages

-

Hobbing Machines LC 180/280

8 Pages