Catalog excerpts

LESER at a glance The-Safety-Valve.com AT_A_GLANCE_GB_2011.indd 2 09.05.12 10:31

Open the catalog to page 1

Valve finder High operating to set pressure ratio, high backpressure or low total height? Yes High Efficiency Yes Clean Service Yes Mediumcontrolled Product Group Critical Service No Clean Service application? Critical Service / highly corrosive application? No Yes API No Steam, gas and liquid application with low capacity in relation to valve size? Yes Modulate Action Spring loaded API specified application? Safety Relief Valves No No Orifice ≥ F High Performance Required Orifice letter? Compact Performance AT_A_GLANCE_GB_2011.indd 3 Yes Best Availability Bursting disc Additional...

Open the catalog to page 2

Safety Valves Process and General Industrial Safety Valves API meets all requirements of the API 526 norm and includes the entire orice D to T product range. Series 526 Applications Product features • Refineries • Valve sizes 1" through 8", Orifice D through T • Chemical industry • Materials: WCB, CF8M, WC6, LCB, specials • Petrochemical industry • Design according to API 526 • Oil and gas – Onshore and Offshore • Great variety of options and flanged connections available • Standard metal sealing • Single trim for steam, gas and liquid Type 526 Compact Performance has compact dimensions...

Open the catalog to page 3

Safety Valves Specialties Clean Service has the highest aseptic characteristics, has minimum dead space, and allows easy cleanability. Series 48x Applications • Pharmaceutical industry • Valve sizes DN 25 through DN 100, 1" through 4" • Breweries Type 485 Product features • Great variety of aseptic connections • Food and beverage industry • Cosmetic industry (e. g. clamps, flanges) and option to fit any application • Materials: Stainless steel 316L, 1.4404, 1.4435 and specials • Minimum dead leg design and flush-mounting capability • Soft seat (FDA compliant elastomers) for superior...

Open the catalog to page 4

Safety Valves Medium controlled Increase the efciency of your plant by using • Higher operating pressure than is possible with regular spring-loaded safety valves, as High Efciency safety valves guarantee tightness right until set pressure. • Lower media loss during blow-off because High Efciency safety valves have low opening and reseating pressure differences. • Safe operation irrespective of back pressure due to the fact that back pressure has no inuence on the opening characteristics of High Efciency safety valves High Efficiency Series 800 – Pilot Operated Safety Valve Applications...

Open the catalog to page 5

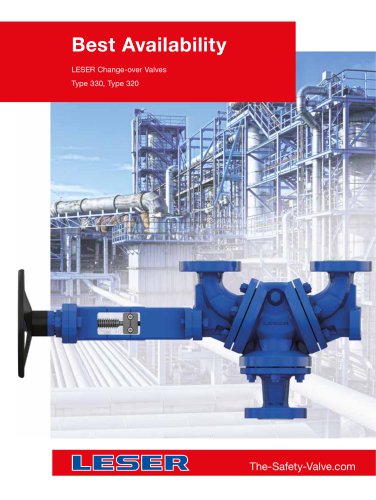

Safety Valves Additional components Change-over valves are used to connect two safety valves to a pressure system. One safety valve is in operation and the other one is on standby. The safety valve on standby can be dismounted and serviced during ongoing operation of the system – the protection of the system against excessive pressure remains guaranteed. Best Availability Type 310 and 311 XXL – Change-over Valves Applications Product features Change-over Valves are used in plants which cannot or • Uninterrupted operation should not be switched off such as: • Simple handling • Storage tanks...

Open the catalog to page 6

® VALVESTAR ® VALVESTAR The-Safety-Valve.com The sizing software for safety valves LESER GmbH & Co. KG 20537 Hamburg, Wendenstr. 133-135 Fon +49 (40) 251 65-100 E-Mail: sales@leser.com 20506 Hamburg, P.O. Box 26 16 51 Fax +49 (40) 251 65-500 www.leser.com VALVESTAR®, the sizing program for safety valves developed by LESER, supports all leading worldwide codes and standards. In addition to calculations and sizing the program provides user designed and configurable individual reports for technical documentation and archiving. Program highlights Sizing: Settings: • Sizing of safety valves...

Open the catalog to page 7

Proven Technology Flanged Safety Relief Valves LESER safety relief valves have been optimized, in close cooperation with plant engineers and service specialists, simplifying design with fewer components for less down time, fewer spare parts and lower maintenance costs. Integral cast support brackets for safe handling of the valves (API and heavy safety valves). One piece spindle allows better alignment. Guiding: Upper and lower guiding with small surface areas help reduce friction, a major cause of galling. Long spring allows large pressure range for each spring thus drastically reducing...

Open the catalog to page 8

Proven Technology Compact Performance Safety Relief Valves One piece spindle reduces friction and allows better alignment. Long spring allows large pressure range for each spring thus drastically reducing the overall number of different springs. Single trim for steam, gas and liquids for fewer spare valves in your stock. Stellited or hardened metal sealing for longer product life. Metal Seat Soft seat solutions for superior tightness Two designs: O-ring disc or plastic seat O-ring Threaded or anged connections for optimized adaption to the plant. Male thread Female Thread Threaded...

Open the catalog to page 9

The Company LESER GmbH & Co. KG With more than 600 employees, LESER is the largest manufacturer of safety valves in Europe and a leader in its market worldwide. LESER safety valves are developed for the international market at our headquarters in Hamburg and tested on our certified test stand. Production, with a capacity of over 130,000 valves a year, takes place at our modern factory in Hohenwestedt. Eight subsidiaries in Europe, America, the Middle East, and Asia, as well as authorized and trained representatives in over 80 countries guarantee competent consulting for all industrial...

Open the catalog to page 10

Why LESER 7 good reasons to use LESER safety valves Availability 1 LESER is known for short response and short delivery times. This is secured by the factory as well as by the 26 central warehouses worldwide and 66 LESER authorized repair centers (LARCS). Unlike the competitors LESER keeps a high stock of raw material ready. This fact together with a high degree of vertical integration allows quick deliveries within 3 days as well as fast track within 24 hours for all standard safety relief valves. Global Player 2 LESER’s sales network is present in all core markets around the world. This...

Open the catalog to page 11All LESER GmbH & Co. KG catalogs and technical brochures

-

LESER Change-over Valves

32 Pages

-

Critical_Service_Catalog_EN

73 Pages

-

Clean_Service_EN

68 Pages

-

API_Catalog_E_09_2011

128 Pages

-

High_Performance_Catalog_1_EN

148 Pages

-

Catalog_High_Performance_2_EN

144 Pages