Catalog excerpts

Critical Service LESER worldwide André Ramseyer AG Flamatt, Switzerland info@ramseyer.ch LESER UK Bristol, Great Britain sales@leser.co.uk Flanged Safety Relief Valves Series 447 Series 546 Hong Kong LESER Shenzen, China sales@leserchina.com LESER Polska Poznan, Poland leser@leser.pl LESER S.A.R.L. Toulouse, France contact@leser.fr LESER LLC Charlotte (NC), USA salesus@leser.com LESER LTDA. Rio de Janeiro, Brazil leser.vendas@leser.com.br LESER LLP Singapore sales@leser.com.sg LESER Office Middle East Bahrain gopal.n@leser.com LESER representatives FAINGER LESER Valves Mumbai, India info@fainger.com LESER stock and local assembly CATALOG Critical Service Edition April 2012 / 1.000 0777.5648 The-Safety-Valve.com LESER GmbH & Co. KG 20537 Hamburg, Wendenstr. 133-135 20506 Hamburg, P.O. Box 26 16 51 Fon +49 (40) 251 65-100 Fax +49 (40) 251 65-500 E-Mail: sales@leser.com www.leser.com The-Safety-Valve.com E

Open the catalog to page 1

Product range LESER safety valves for every industrial application Critical Service H 2S O 4 HNO3 NH3 HCL High Performance Series 447 Type 447 Type 449 Compact Performance Series 546 Type 546 API Clean Service Modulate Action Best Availability Type 5466

Open the catalog to page 2

Contents Overview Page General information LESER Type Page Type 447 Valve finder and Level-Concept 8 • Dimensions and weights Metric and US units 29 • Pressure temperature ratings Metric und US units 30 Order information Flange drillings • Spare parts 31 31 Available options 32 33 Capacities – Metric units Steam, Air, Water 34 35 • Lining materials • PTFE materials • Comparison PTFE / PFA • Comparison of Critical Service – API 10 11 14 Configuration features Design features – Type 447 • Isostatical manufacturing process 12 13 • How to use Characters and symbols Flange drillings and facings...

Open the catalog to page 4

Contents LESER Type Page Type 546, 5466 37 Materials – Type 546 • Conventional design – Level 1 • Balanced bellows design – Level 1 38 40 • Materials – Type 5466 PTFE bellows design – Level 2 42 • How to order Article numbers 44 • Dimensions and weights Metric units 46 Pressure temperature ratings Metric units 47 Type 449 55 56 Protective gas flushing design 56 How to order • Article numbers 57 • Dimensions and weights Metric units 58 • How to order Specification sheet 59 Options 61 Overview 62 Caps and levers 64 Bellows design 66 Sealing plate 68 Lift indicator 69 Lift restriction 70 53...

Open the catalog to page 5

General information General Information LESER – ritical Service Safety Valves C Applications The Critical Service product group represents LESER – Critical Service Safety Valves tandardised solutions for special applications such as S provide solutions for protection against highly corrosive and toxic media in all industrial applications with vapours, gases and fluids. Lined LESER safety valves are used primarily in chemical, pharma eutical, petrochemical and industrial process engic neering. those involving critical and toxic media ptimal and permanent corrosion protection for chemical O...

Open the catalog to page 6

General information Valve finder How to find the right product group Yes High Efficiency Yes Clean Service Yes Critical Service Mediumcontrolled High operating to set pressure ratio, high backpressure or low total height? No Clean Service Application? Critical Service / highly corrosive application? No Yes API No Steam, gas and liquid application with low capacity in relation to valve size? Yes Modulate Action Spring loaded API specified application? Safety Relief Valves No No Orifice ≥ F High Performance Required Orifice letter? Compact Performance Yes Best Availability Burstingdisc...

Open the catalog to page 7

How to find the right Critical Service safety valve Type Orifice Level Corrosion resistance Description 447 Inlet Outlet G–N 3 Bonnet space – tandard with S PTFE-bellows Type 447 is an economical alternative for applications in which there is also a highly corrosive atmosphere in the outlet body which requires the best protection through a PTFE lining. 5466 Inlet Outlet G–K 2 Bonnet space – tandard with S PTFE-bellows Type 5466 is the solution for applications in which activation of the safety valve rarely occurs and the protective coating together with the bellows provides adequate...

Open the catalog to page 8

General information Valve finder and Level-Concept How to find the right Critical Service safety valve Type Design features 447 • Inlet body and outlet body are lined with virgin PTFE for the utmost corrosion resistance • ozzles made of gas-tight sintered PFTE-TFM + 25% glass for the prevention of corrosion in the inlet of the body. N • ealing plate made of BOROFLOAT glass for high chemical resistance. A metallic sealing plate support ensures S high mechanical stability of the disc unit. Material coupling in PTFE-nozzle – disc with sealing plate made of BOROFLOAT glass for high...

Open the catalog to page 9

General information Lining materials PTFE materials Polytetrafluorethylene (PTFE) is a high-performance plastic which is known for its unique properties. Several different types of this universal material are used at LESER. For 25% glass-modified PTFE TFMTM, fibre glass is added to the production process to improve impact and compression strength. An overview of the types of materials used: For 25% carbon-modified PTFE TFMTM, graphite carbon is added to the production process to achieve a lower volume resistance and also improve impact and compression strength. Virgin PTFE-TF stands for a...

Open the catalog to page 10

General information Lining materials Comparison PTFE / PFA The following is a comparison of the properties of the widely used PFA and PFTE, which is LESER uses exclusively. Comparison of the lining materials PTFE / PFA PTFE – Isostatic lining [Polytetrafluorethylene] PFA [Perfluoralkoxy-Copolymere] Semi-crystalline fluoro-plastic Semi-crystalline copolymere Processing in an isostatic compression moulding process followed by a gas-tight sintering process Processing in melted state – injection mouldable as a result: Process-reliable isostatic lining High degree of shrinkage due to process,...

Open the catalog to page 11All LESER GmbH & Co. KG catalogs and technical brochures

-

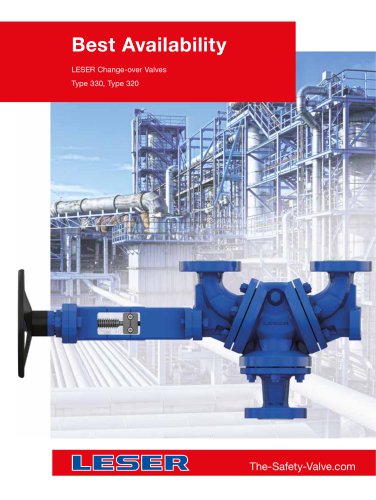

LESER Change-over Valves

32 Pages

-

Clean_Service_EN

68 Pages

-

API_Catalog_E_09_2011

128 Pages

-

High_Performance_Catalog_1_EN

148 Pages

-

Catalog_High_Performance_2_EN

144 Pages

-

LESER_At_a_glance_EN

12 Pages