Catalog excerpts

High Performance Flanged Safety Relief Valves Series 441 Full nozzle Series 458 CATALOG 2 The-Safety-Valve.com

Open the catalog to page 1

Product Range LESER Safety Valves for every industrial application High Performance Compact Performance Series 441 Full nozzle Type 441, 442 Full nozzle DIN Type 441, 442 Full nozzle ANSI API Series 458 Type 455, 456 Type 457, 458 Clean Service Series 441 Type 441, 442 DIN H 2S O 4 Critical Service Type 441, 442 ANSI HNO3 NH3 HCL Series XXL Modulate Action Best Availability Type 441, 442 XXL Series 444 Type 444 DIN Type 444 ANSI to refer ease rmance Pl Perfo High atalog 1 C

Open the catalog to page 2

Type 441, 442 Full nozzle ANSI Valve size 1" – 4" Set pressure 0,1 – 51 bar, 1,5 – 740 psig Flanges according to ASME B16.5 Type 455, 456 DN 25 – 100, 1" – 4" Set pressure 2,5 – 100 bar, 36 – 1450 psig Flanges according to DIN EN 1092 and ASME B16.5 Type 457, 458 DN 25 – 150, 1" – 6" Set pressure 2,5 – 300 bar, 36 – 4350 psig Flanges according to DIN EN 1092 and ASME B16.5 General Type 441, 442 Full nozzle DIN Type 441, 442 Full nozzle ANSI DN 20, 40, 50 Set pressure 0,1 – 40 bar, 1,5 – 580 psig Flanges according to DIN EN 1092 Type 456, 456 Type 441, 442 Full nozzle DIN Type 457, 458...

Open the catalog to page 3

Contents Overview Chapter/Page General Applications, General design features Valve finder Valve selection How to use: Determination of coefficient of discharge Kdr / α w How to use: Capacity sheets 00/09 LESER Effective Orifice LEOS/G 00/11 LESER Effective Orifice LEOL 00/12 Sour gas service 00/13 07/14 07/15 07/16 Approvals Capacities • Steam • Air • Water 00/08 07/12 07/13 Flange drillings and facings Order information – Spare parts Available options 00/07 07/10 07/11 Pressure temperature ratings • Metric Units • US Units 00/05 How to use: Signs and symbols, Flange drillings and facings...

Open the catalog to page 4

Contents Type 457, 458 09/01 Materials • Conventional design • Balanced bellows design 09/02 09/04 Type 441, 442 How to order • Numbering system • Article numbers 09/06 09/08 Dimensions and weights • Metric Units • US Units 09/10 09/11 Materials How to order Dimensions and weights Pressure temperature ratings Flange drillings and facings Order information – Spare parts Available options Approvals Capacities Determination of coefficient of discharge Kdr /α w Pressure temperature ratings • Metric Units • US Units 09/12 09/13 Type 441, 442 XXL Flange drillings and facings Order information –...

Open the catalog to page 5

General General Information LESER – High Performance Safety Valves The High Performance product group represents ✓ High capacity related to the safety valve size ✓ High customisability ✓ Excellent price / performance ratio LESER´s High Performance Safety Valves • • • • • • • • Are designed to meet all industrial applications. Open rapidly with an overpressure of 5 % to the full design lift. Are used particularly for vapours and gases where the maximum mass flow has to be discharged rapidly. Have a maximum blowdown of minus 10 % for steam/gas service and minus 20 % for liquid service. Are...

Open the catalog to page 6

General General Information Applications General Design Features LESER – High Performance Safety Valves LESER´s High Performance Safety Valves are the ultimate solution for all industrial applications for steam, gas and liquid. offer a large variety of types, materials and options to suit any application: Typical applications for LESER High Performance Safety Valves are: • • Series 441 • Protection of chemical processes and equipment (e.g. distillation columns) • Heat exchangers • Low and medium pressure steam • Blowers and turbo compressors • • 14 valve sizes from DN 20 to DN 400 – 3/4" to...

Open the catalog to page 7

General Valve finder How to find the right Product Group Orifice > F Required Orifice letter? High Performance Orifice < F Compact Performance No Steam, gas and liquid application with low capacity relating to the valve size? Yes Modulate Action No API specified application? Yes API No Critical Service / High Corrosive application? Yes Critical Service Yes Clean Service No Clean Service application? How to find the right Safety Valve Product Group 00/03 LWN 488.01-E

Open the catalog to page 8

General Valve finder How to find the right Safety Valve DIN EN ISO ASME B16.5 Flange standard? No Full nozzle-design required? ≤ PN40 / CL300 Flange rating? Type 441 DIN Type 442 DIN Type 441 ANSI Type 442 ANSI DIN EN ISO ASME B16.5 Yes Type 441 Full nozzle DIN Type 442 Full nozzle DIN Type 441 Full nozzle ANSI Type 442 Full nozzle ANSI ≥ PN63 / ≥ CL600 Semi nozzle up to 100 bar / 1450 psig Full nozzle up to 400 bar / 5800 psig ≤ DN 150 / 6" ≥ DN 200 / 8" Valve size, inlet? Series 458 Type 455 Type 456 Type 457 Type 458 Type 441 XXL Type 442 XXL General industry Stainless steel...

Open the catalog to page 9

General How to use General signs and symbols * This option is covered by standard design ✓ Available – Not possible Signs and symbols for flange drillings and flange facings * Standard design, no option code required (*) Flange dimensions except flange thickness are in accordance with flange standard (e.g. ASME B16.5) Flange thickness is smaller (max. 2 mm), see “Multiple pressure rating” – Flange drilling/facing is not possible Option code for flange drilling and dimension, e.g. H50 H50 Flange drilling as specified in flange standard Outer flange diameter, flange thickness and height of...

Open the catalog to page 12

Sample Determination of Kdr/ocw: Type 441, 442 Full nozzle DIN, DN 25 TVpe 441, 442 Full nozzle DIN LI Determination of coefficient of discharge in case of lift restriction or back pressure Diagram for evaluation of ratio of lift/flow diameter (h/d0) in reference to the coefficient of discharge (Kd,/a„) d0 = Flow diameter [mm] of selected safety valve, refer to table article numbers h/do = Ratio of lift / flow diameter p30 = Back pressure [barj Pa/Po = Ratio of back pressure / set pressure Kb = Back pressure correction factor Ratio of lift / flow diameter h / d0 -»- Diagram for evaluation...

Open the catalog to page 13All LESER GmbH & Co. KG catalogs and technical brochures

-

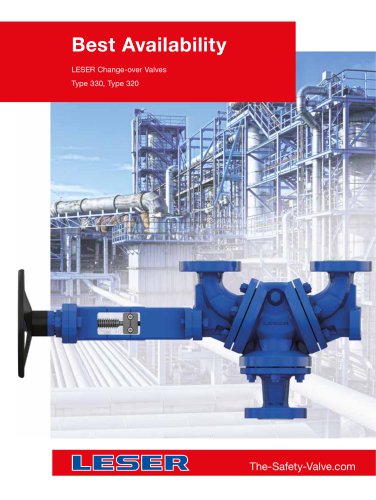

LESER Change-over Valves

32 Pages

-

Critical_Service_Catalog_EN

73 Pages

-

Clean_Service_EN

68 Pages

-

API_Catalog_E_09_2011

128 Pages

-

High_Performance_Catalog_1_EN

148 Pages

-

LESER_At_a_glance_EN

12 Pages