Website:

LENSER Filtration GmbH

Website:

LENSER Filtration GmbH

Catalog excerpts

LENSER i-Plate VISIBLE CONTROL OF MEMBRANE FILTER ELEMENTS

Open the catalog to page 1

LENSER i-Plate VISIBLE CONTROL OF MEMRANE FILTER ELEMENTS SENSOR TECHNOLOGY FOR MOISTURE MEASUREMENT IN REAL TIME NEW PERSPECTIVES FOR YOUR FILTRATION PROCESS PRECISE DATA FOR TARGETED PROCESS OPTIMISATION LENSER i-PLATE SERVICE PACKAGES LENSER i-PLATE: TECHNICAL DETAILS AT A GLANCE

Open the catalog to page 2

SENSOR TECHNOLOGY FOR MOISTURE MEASUREMENT IN REAL TIME The LENSER i-Plate opens up completely new insights into your individual filtration process. Reliable, digital real-time measurement provides you with a wide range of relevant data from your filter press during ongoing operation. In this way, you gain insights into your processes and can optimize them. Process monitoring is becoming increasingly important in the field of filter presses. Countless parameters have long been recorded and evaluated before and after the filtration process. However, these methods all have one decisive...

Open the catalog to page 3

NEW PERSPECTIVES FOR YOUR FILTRATION PROCESS PRECISE DATA FOR TARGETED PROCESS OPTIMISATION At LENSER, we think outside the box. With the LENSER i-Plate you will have new process data and be able to identify parameters to improve your processes. This will accelerate your cycles and power your business more efficiently. This measurement is made possible by electromagnetic waves in the frequency range from 500 MHz to 1,000 MHz. The sensor constantly evaluates the changes in radar wave propagation time due to varying dielectric constants in the suspension. The electromagnetic field energy is...

Open the catalog to page 4

LENSER i-PLATE SERVICE PACKAGES LENSER offers you four different LENSER i-Plate service packages which build on each other, so that the customer can choose which service support fits best. For further questions please ask your #FiltrationExpert. This sensor technology is operated with a common voltage of 12 to 24 V. Of course, the cable is mounted in such a way that it is not damaged when the filter press is opened and closed. WITH A NEW LOOK INTO THE FUTURE For the first time, the LENSER i-Plate makes it possible to take a look inside the filter chamber and display the filtration process...

Open the catalog to page 5

LENSER i-PLATE: TECHNICAL DETAILS AT A GLANCE LENSER i-PLATE – TECHNICAL DATA Measurement range for moisture Measurement range for temperature Measurement range for electrical conductivity V4A High-grade steel and ceramics Chemicals, minerals, mining and environment Sizes (filter elements) Maximum filtration pressure According to the specification of the recessed filter element Maximum wash pressure Size (Sensor) 2 analog outputs and 1 digital output Power supply

Open the catalog to page 6

What are the challenges in your filtration process? Even the smallest adjustment in your process flow can make a big difference. Filter cloths also contribute significantly to the success of sustainable filtration. LENSER is the first port of call and a competent partner in choosing the right filter cloth for your application. Our selected supplier network guarantees optimum solution procurement for any application. Trust in our many years of expertise. LENSER Filtration GmbH Breslauer Strasse 8 89250 Senden Germany All data, information, statements, photographs and graphic illustrations in...

Open the catalog to page 7All LENSER Filtration GmbH catalogs and technical brochures

-

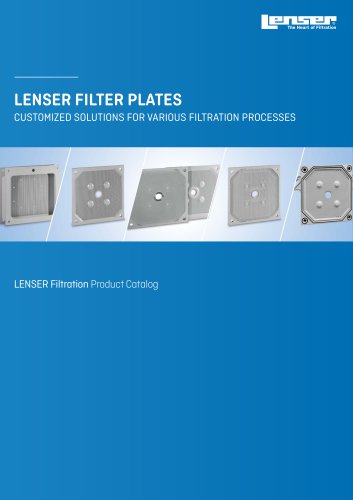

LENSER_Product_Catalog

19 Pages

-

Product brochure

2 Pages

-

Product Brochure

2 Pages

-

Product brochure

2 Pages

-

Productbrochure

2 Pages

-

Product brochure

2 Pages

-

Product brochure

2 Pages

-

LENSER MCS Leaflet

2 Pages

-

Product brochure

2 Pages

-

Product Brochure

2 Pages

-

Product Brochure

2 Pages

-

Product overview

2 Pages

-

LENSER Press Tex

10 Pages

-

LENSER PRESS TEX

10 Pages

-

LENSER PRESS TEX

10 Pages

-

i-Plate product information

4 Pages

-

Image brochure

16 Pages