Catalog excerpts

Plastic Fabrication PLASTIC WELDING Extrusion and hot-air hand welders The right choice for the specialist

Open the catalog to page 1

Dear Leister customers The selection of machines and equipment greatly influences the quality and success of your work. That is why we offer solutions that you can always count on and with which you are guaranteed to be able generate added value. Our goal is to exceed your expectations. All of our devices and machines are designed and produced in Switzerland, because for us, quality and innovation are the highest priority. We have more than 65 years of experience in the fields of plastic welding and industrial process heat applications, and are constantly expanding this. Through direct...

Open the catalog to page 3

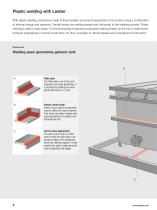

Plastic welding with Leister With plastic welding, workpieces made of thermoplastic are joined inseparably to one another using a combination of thermal energy and pressure. Central factors are welding speed and the length of the welding process. Plastic welding is used in many areas: For the processing of tarpaulins and plastic sealing sheets, on the roof, in earthworks, hydraulic engineering or tunnel construction, for floor coverings, in vehicle repairs and in equipment construction. Welding seam geometries galvanic tank Fillet weld The fillet weld is one of the most frequently-use seam...

Open the catalog to page 4

Possibilities of welding seams a = seam size s = material thickness α = milling angle Fillet welding seam Corner outside seam Overlap seam X-seam The double-V seam is also known as an X-seam. It is a type of butt weld and consists of a combination of two V-seams on each of the two sides of the components to be joined. V-seam In order to achieve the V-shaped angle that is typical for the V-seam, the workpieces are either beveled or positioned at an appropriate angle to each other. Lap seam Lap seams are mainly used for plastic sheets. Here, the sheets are arranged on top of each other and...

Open the catalog to page 5

FUSION 2, compact and powerful Thermal joining of plastics Plastic welding requires a correspondence between the three welding parameters temperature, pressure and speed. In contrast to other joining methods, welding can achieve high resiliency and a strong, homogeneous welding seam. Plastic compounds are extremely robust and perfectly sealed when processed correctly. They can also be repaired without a loss of strength. Hot gas welding with the torch separate from filler rod (WF) Hot gas welding with the torch separate from filler rod is used primarily for areas that are difficult to...

Open the catalog to page 6

Welding Process Free hand welding (WF) Draw welding (WZ) High-density polyethylene Polypropylene, Types 1, 2, 3 Unplasticised polyvinyl chloride Chlorinated polyvinyl chloride Polyvinylidene fluoride Acrylonitrile butadiene styrene Polycarbonate Polyamide Polybutylene terepht-halate Low-density polyethylene Polyurethane XENOY Plasticised polyvinyl chloride Polyethylene terephthala-te glycol-modified Polyvinyl chloride Polypropylene, Types 1, 2, 3 Unplasticised polyvinyl chloride Chlorinated polyvinyl chloride Polyvinylidene fluoride Ethylene Chloro Tri Fluoro Ethylene Fluorinated ethylene...

Open the catalog to page 8

Extrusion welding (WE) High-density polyethylene Polypropylene, Types 1, 2, 3 Unplasticised polyvinyl chloride Impact resistant polyvinyl chloride Chlorinated polyvinyl chloride Polyvinylidene fluoride Polyamide 6 6) Polycarbonate 6) Acrylonitrile butadiene styrene 6) Polystirene 6) Polypropylen Athylen Propylen Terpolymer 6) Polyurethane (Thermoplast) 6) 7) PE-HD 4) PP-H; PP-B; PP-R PVC-U PVC-HI PVC-C PVDF PA 6 PC ABS PS PP-EPDM PUR 11 Measured with an insert thermometer at the exrudate outlet of the hand extruder. 2) Measured 5mm in the nozzle, in the centre of the nozzle opening. 3)...

Open the catalog to page 9

Welding errors In addition to a failure to adhere to the welding parameters, the following errors can lead to cavities, vacuoles and poor weld quality: •• Excessively high temperature •• Residual moisture in the welding filler •• Excessively high air humidity •• Wet hands •• Excessively cold welding shoe •• Low-quality plastic Base material and welding filler made of polyolefins can absorb moisture. The thicker the seam, the more frequently these phenomena occur. For this reason, you should store materials in a dry place and in their original packaging. You should avoid temperature...

Open the catalog to page 10

Fields of application Hot gas welding with the torch separate from filler rod, highspeed hot gas welding and hot gas extrusion welding are used in many areas. General tank construction Plastic is preferred for producing receptacles and tanks. Depending on the storage medium, they have significant advantages over metallic materials. Galvanic Galvanic processes are usually carried out using chemicals. The baths must also be resistant to thermal and electrical influences. Water management Fresh water and service water infrastructures place high demands on hygiene and corrosion. Thermoplastics...

Open the catalog to page 11

WELDPLAST - Closed loop system FUSION - Open loop system •• Closed-loop control •• Little welding experience required •• Integrated display and temperature probe •• recise temperature independent of environmental factors or P quality of voltage source -> process reliability •• DVS-compliant •• Open-loop control •• Requires more welding experience •• Neither display nor temperature probe •• emperature depends on environmental factors and voltage T source open-loop close-loop Closed loop system Open loop system power electronic heating element power electronic heating element

Open the catalog to page 12

The benefits of Leister at a glance: Device components Robust, corrosion-resistant components High welding speeds and top performance Durable heating elements Ergonomic design Intuitive to use Made in Switzerland Service Everything available from a single source thanks to a wide product range Tight distribution network with short delivery times Support and device demonstration by our field service representatives Complete quality check before delivery Quick repair and service Long spare parts guarantee when discontinued after 7 years

Open the catalog to page 14All LEISTER Technologies AG catalogs and technical brochures

-

Process Heat

84 Pages

-

MISTRAL PREMIUM / SYSTEM

96 Pages

-

BASIC S/M/L

2 Pages

-

COMET

108 Pages

-

TWINNY S

52 Pages

-

Plastic Welding

160 Pages

-

General Catalog Process Heat

80 Pages

-

HOTWIND PREMIUM HOTWIND SYSTEM

140 Pages

-

Laser Plastic Welding

28 Pages

-

UNIFLOOR 500

2 Pages

-

Accessories Catalog

20 Pages

-

Hot-air hand tool SOLANO AT

4 Pages

-

Laser Textile Welding

2 Pages

-

Laser welding BASIC S

4 Pages

-

Blower AIRSTREAM ST

4 Pages

-

Automatic welders VARIANT T1

4 Pages

-

Automatic welders MINIFLOOR

4 Pages

-

Wedge welder GEOSTAR G5/G7

4 Pages

-

Hot-air hand tool GHIBLI AW

4 Pages

-

Hot-air hand tool FUSION 1

4 Pages

-

Flooring / Interior Decoration

24 Pages

-

Roofing

36 Pages

-

Welding Machine HEMTEK K-ST

4 Pages

-

Laserwelding

2 Pages

-

accessories Plastic Welding

2 Pages

Archived catalogs

-

General Catalog Plastic Welding_2020

127 Pages

-

Hot-Air Hand Tools

26 Pages

-

Billboards / Tarpaulins

12 Pages

-

BR - Infrared Sources

8 Pages

-

BR - Micro-Optics

12 Pages

-

General Catalog Plastic Welding_2013

100 Pages

-

TRIAC-BT

7 Pages

-

TAPEMAT SPRIEGEL

3 Pages

-

TRIAC-AT

5 Pages

-

Triac ST, the new S

4 Pages

-

Leister - Triac ST

4 Pages

-

Laser Diode Gas Detectors

4 Pages

-

The LE air heater family.

8 Pages

-

Ignition Blower

4 Pages

-

Welding floor coverings

7 Pages

-

Vehicle repairs

7 Pages

-

Shrinking

7 Pages