Catalog excerpts

INDUSTRIAL-DUTY & COMMERCIAL-DUTYElectric MotorsGear ReducersGearmotorsAC & DC Drives >

Open the catalog to page 1

XI. Engineering Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78 XII. Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81 Temperature Conversion Table Mechanical Characteristics Table Electrical Characteristics Table Fractional/Decimal/Millimeter Conversion VI. Metric (IEC) Designations . . . . . . . . . . . . . . . . . . . . . . .40 VII. Motor Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45 X. Adjustable Speed Drives . . . . . . . . . . . . . . . . . . . . . . . . .68 IEC Enclosure Protection Indexes IEC...

Open the catalog to page 4

Electric motors are the versatile workhorses of industry. In many applica-tions, motors from a number of manufacturers can be used.Major motor manufacturers today make every effort to maximize interchangeability, mechanically and electrically, so that compromise does not interfere with reliability and safety standards. However, no manufacturer can be responsible for misapplication. If you are not certain of a replacement condition, contact a qualified motor distributor, sales office or service center. > Use safe practices when handling, lifting, installing, operating, andmaintaining motors...

Open the catalog to page 8

Much of this information consists of standards defined by the NationalElectrical Manufacturers Association (NEMA). These standards are widely used throughout North America. In other parts of the world, the standards of the International Electrotechnical Commission (IEC) are most often used. > Nameplate data is the critical first step in determining motor replacement. Much of the information needed can generally be obtained from the name- plate. Record all nameplate information; it can save time and confusion. > Catalog number.ՕMotor model number. Frame. ՕType (classification varies from...

Open the catalog to page 9

Alternating current (AC) induction motors are divided into two electricalcategories based on their power source single phase and polyphase (three phase). > Types of single-phase motors are distinguished mostly by the way they are started and the torque they develop. > motors have low starting torque, low cost, low efficiency,and no capacitors. There is no start switch. These motors are used on small direct drive fans and blowers found in homes. Shaded pole motors should not be used to replace other types of single-phase motors. > motorshave applications similar to shaded pole, except much...

Open the catalog to page 11

A heavy-duty polyphase motor with cast-iron frame. >

Open the catalog to page 13

DC motors can be operated from rectified alternating cur- rent of from low-voltage bat- tery or generator source.This is a low-voltage design,which includes external connection lugs for the input power.With the rear endshield removed, as in this view,the brush assemblies and commutator that form a DC motors elec- trical heart are clearly visible. > Speed reduction gearing is visible in this cutaway view of a parallel-shaft gearmotor.Shown is a small, sub-fractional horsepower gearmotor. -14- >

Open the catalog to page 15

Gearmotors may be either integral, meaning the gear reducer and motorshare a common shaft, or they may be created from a separate gear reducer and motor, coupled together. Integral gearmotors are common in sub-fractional horsepower sizes; separate reducers and motors are more often the case in fractional and integral horsepowers. For more on gear reducers and gearmotors, see Chapter IX. > A brakemotor is a pre-connected package of industrial-duty motor and fail- safe, stop-and-hold spring-set brake. In case of power failure, the brake sets, holding the load in position. Brakemotors are...

Open the catalog to page 16

Totally Enclosed Non-Ventilated (TENV) > Totally Enclosed Fan Cooled (TEFC) motors have no vent openings.They are tightly enclosed to prevent the free exchange of air, but are not air tight. TENV motors have no cooling fan and rely on convection for cooling. They are suitable for use where exposed to dirt or dampness, but not for hazardous locations or applications having frequent hosedowns. motorsare the same as TENV except they have an external fan as an integral part of the motor to provide cooling by blowing air over the outside frame. Totally Enclosed Air Over motors are specifically...

Open the catalog to page 17

Class I (Gases, Vapors) Group AAcetylene Group B Butadiene, ethylene oxide, hydrogen, propylene oxideGroup C Acetaldehyde, cyclopropane, diethlether, ethylene, isopreneGroup D Acetone, acrylonitrile, ammonia, benzene, butane, ethylene dichloride, gasoline, hexane, methane, methanol, naphtha, propane, propylene, styrene, toluene, vinyl acetate, vinyl chloride, xylene Explosion Proof motors meet Under-writers Laboratories or CSA standards for use in the hazardous (explosive) locations shown by the UL/CSA label on the motor. The motor user must specify the explosion proof motor required....

Open the catalog to page 18

Contact FactoryContact Factory ATEX compliant motorsATEX compliant motors Class I Area ClassificationClass II Area Classification*Class I Area Classification Division 1 Explosion Proof/Zone 1 FlameproofDivision 2/Zone 2 Non-Sparking (Group C as noted), Sine wave Groups F & G, Sine waveor PWM poweror PWM power Explosion Proof - Class I, Group D(Group C as noted) Explosion Proof - Class I, Group DExplosion Proof - Class II, (Flammable Gases, Vapors or Mists)(Combustible Dusts)(Flammable Gases, Vapors or Mists) CODES TEMPERATURE CT4T4 O CT2AT2(280) CT2BT2(260)215 CT2DT2(215)200 CT3BT3(165)...

Open the catalog to page 20

Frame numbers are not intended to indicate electrical characteristics suchas horsepower. However, as a frame number becomes higher so in general does the physical size of the motor and the horsepower. There are many motors of the same horsepower built in different frames. NEMA (National Electrical Manufacturers Association) frame size refers to mounting only and has no direct bearing on the motor body diameter.In any standard frame number designation there are either two or threenumbers. Typical examples are frame numbers 48, 56, 145, and 215. The frame number relates to the DӔ dimension...

Open the catalog to page 21All LEESON Electric catalogs and technical brochures

-

Tobacco Barn Motors

1 Pages

-

Farm Ag Motors Bulletin 1040

12 Pages

-

IEC Brochure Bulletin 1855

8 Pages

-

Large Motors Bulletin 1304

6 Pages

-

Pulleys Catalog 1060

84 Pages

-

EPACT Supplement

56 Pages

-

Bulletin 1400

8 Pages

-

Bulletin 1600IEC

36 Pages

-

Bulletin 1700

5 Pages

-

Energy Efficiency Brochure

6 Pages

-

Bulletin 1830

8 Pages

-

Fire Pump Motors

9 Pages

-

Bulletin 7052

8 Pages

-

VVVF Elevator Hoist Motors

1 Pages

-

MOTORS FOR AGRICULTURE

24 Pages

-

Bulletin 1055

8 Pages

-

Product Catalog 1050

534 Pages

-

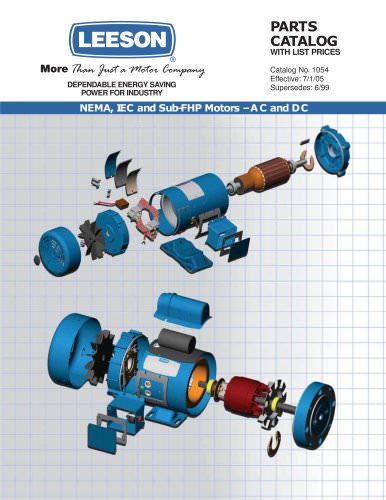

parts Catalog

61 Pages