Catalog excerpts

ENGINEERING YOUR SPRAY SOLUTION JEWUR FLEX your cooling. Improved strand quality through optimized cooling.

Open the catalog to page 1

New challenges in continuous casting In 2002, Lechler introduced the first generation of Billetcooler nozzles for secondary cooling in continuous casting applications. Since then, we have equipped more billet and bloom casters with air mist nozzles than any other supplier. However, new steel grades as well as an extended range of billet and bloom formats mean new challenges for secondary cooling. That is why we are continuously further developing our nozzles. One example of this is the new Billetcooler FLEX® air mist nozzle.

Open the catalog to page 2

GOOD COOLING IS A QUESTION OF QUALITY With today‘s standard diameters of up to 1,000 mm, bloom casters place signifi cantly higher demands on cooling compared to smaller formats. New steel grades and increas ing format sizes are signifi cantly more susceptible to cracking and demand much more homogeneous cooling with reduced water flow rates. Secondary cooling in con tinuous casting machines for long products normally consists of several cooling zones. The nozzle arrange ment is usually defined for a specific format range. In order to permit casting of different steel grades under...

Open the catalog to page 3

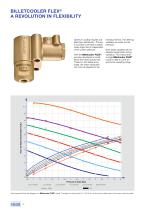

BILLETCOOLER FLEX® A REVOLUTION IN FLEXIBILITY Optimum cooling requires suit able liquid distribution. The key to success is primarily a stable spray angle that is independent of the current pressure. With the Billetcooler FLEX®, we have developed a nozzle family that does exactly that. Thanks to the stable spray angle, the water distribution can now be adjusted to the individual format. The defining variables are water and air pressure. Both these variables can be adapted dynamically during operation. This means that a single Billetcooler FLEX® nozzle is able to cover an enormous...

Open the catalog to page 4

The new Billetcooler FLEX® nozzle is characterized by its constant spray angle over the entire turn-down range. We offer three different nozzle sizes, each with a turn-down ratio (min./max. water flow rate) of 1:10. Lechler therefore covers the requirements of most bloom and billet casters with just three standard nozzles. This minimizes the number of different nozzles, reduces logistics costs and helps to avoid maintenance mistakes. Example BC FLEX® 60° spray angle nozzle At varying water pressures and with a constant air pressure of 2 bar, the spray coverage of the Billetcooler FLEX® (top...

Open the catalog to page 5

FROM HEAT TRANSFER COEFFICIENT TO RELIABLE COOLING MODEL Spray intensity position position position position position position Thanks to these characteristics, the Billetcooler FLEX® offers greater flexibility in the continuous casting process, since the local heat extraction on the strand can be specifically increased or reduced for the first time. Spray intensity Thanks to these characteri stics, the Billetcooler FLEX® offers greater flexibility in the continuous casting process, since the local heat extraction on the strand can be specifi cally increased or reduced for the first time....

Open the catalog to page 6

The liquid distribution can be controlled by appropriate se lection of the air pressures for comparable water flow rates. As described on the previous page, this allows the local cooling to be adapted to the process-specific requirements. The adjacent figure demon strates the flexibility of the new Billetcooler FLEX® 60° spray angle. For an example nozzle size, the excerpt shows the adjustable liquid distributions as a function of the flow rates with indication of the respec tive air pressures. It is possible to easily see from the diagram how a large ope rating range can be covered...

Open the catalog to page 7

THE RIGHT NOZZLE FOR EVERY FORMAT Optimum spray characte ristics for all formats The optimum spray profile for every format can be realized with the Billetcooler FLEX® by controlling the air pressure. Rectangular long products Billets tend to cool down more quickly at the edges. Spray profiles with a liquid distribution that decreases slightly towards the edges („High Center“) have proven themselves to be suitable for ensuring that the edges are not overcooled. „High Center“ cooling profile Round formats Round formats have a three-dimensional cooling surface. On larger formats in...

Open the catalog to page 8

BILLETCOOLER FLEX® – ADVANTAGES AND BENEFITS Stable spray angle The Billetcooler FLEX® is characterized by its constant spray angle, which is between 60° and 70° over the entire turn-down range. No strand overcooling or undercooling Flexible cooling With Billetcooler FLEX®, the water distribution can be individually adjusted for different formats. Optimum cooling guaranteed at all times Large free cross-sections Blockage-resistant and maintenance-friendly thanks to very large free cross-sections for air and water. High operating reliability New design All nozzle variants of the Billetcooler...

Open the catalog to page 10

As a process engineer at Lechler, I frequently encounter problems relating to instable spray angles and inhomogeneous liquid distribution on the strand when optimizing the secondary cooling systems of long-product casters. This is particularly true for casters with a wide product range and different section sizes where the maximum nozzle turn-down range is used. This frequently results in local undercooling and overcooling as well as quality problems in the form of cracking. The new Billetcooler FLEX® is a tool that I will use specifically to solve these problems for our customers in...

Open the catalog to page 11

World Headquarters Lechler Companies Sales Offices Lechler GmbH · Precision Nozzles · Nozzle Systems P.O. Box 13 23 · 72544 Metzingen, Germany · Phone +49 7123 962-0 · Fax +49 7123 962-333 · info@lechler.de · www.lechler.com ASEAN: Lechler Spray Technology Sdn. Bhd. · No. 23, Jalan Teknologi 3/3A · Taman Sains Selangor 1 · Kota Damansara, PJU 5 · 47810 Petaling Jaya · Malaysia · info@lechler.com.my Belgium: Lechler S.A./N.V. · Avenue Mercatorlaan, 6 · 1300 Wavre · Phone: +32 10 225022 · Fax: +32 10 243901 · info@lechler.be China: Lechler Intl. Trad. Co. Ltd. · Beijing · Rm. 418 Landmark...

Open the catalog to page 12All Lechler catalogs and technical brochures

-

Droplet Separators

16 Pages

-

Descaling Pressure Gauge

2 Pages

-

IDKT

2 Pages

-

IDK / IDKN

2 Pages

-

ID3

2 Pages

-

Pneumatic atomizing nozzles

31 Pages

Archived catalogs

-

Strainers

4 Pages

-

Compressed air nozzles

10 Pages

-

Hollow Cone Nozzles

14 Pages

-

Full Cone Nozzles

14 Pages

-

Pneumatic Nozzles

16 Pages

-

Tank Cleaning Nozzles

20 Pages