Catalog excerpts

1968 ÷ 2018 Machines and components for the automation for over 50 years

Open the catalog to page 1

The LDP was founded in 1968 as a company for pneumatic cylinders and accessories production. After few time, in order to meet internal production requirements, rotary tables, clamps and presses were designed and built, and the common feature of these products is the use of compressed air as motor fluid. The deep-rooted knowledge of the air - oil systems, brought the LDP to get the first patent in the field, granted by the United States, in 1976. The expertise and research in the application of the air-oil system are consolidated in 1979, when the LDP exhibited at III EMO of Milan the full...

Open the catalog to page 3

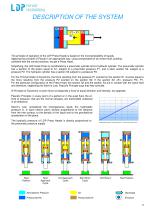

Head Press Hydraulic System Mechanical System HEAD PRESSES Strenght Investment Cost Setting Flexibility Quality of Working Maintenance Drawbacks : till 500 kN. : head press + valves + pneumatic system. : silent thanks to the small impact force on the piece and discharge of a modest amount of air; possibility of use in clean rooms and food industry. : it’s possible to use the working stroke at any point of the approaching stroke. : approaching force and workforce control. Workforce control with a pressure switch or a load cell. Separate adjustment of the approach speed and the speed of work...

Open the catalog to page 4

The principle of operation of the LDP Press Heads is based on the incompressibility of liquids. Applying the principle of Pascal in an appropriate way, using compressed air as motive fluid, building cylinders with the correct sections, we get a Press Head. Simplifying, the LDP Head Press is constituted by a pneumatic cylinder and a hydraulic cylinder. The pneumatic cylinder has a section of the piston equal to S1, subject to a pneumatic pressure P1, and a stem section S2, subject to a pressure P2. The hydraulic cylinder has a section S3 subject to a pressure P3. For the Third principle of...

Open the catalog to page 5

LDP Press Heads: The whole family E-Type e E-type TX - In line version - Unit attack to rods or screw (TX version) - Vertical working Position, stem down ↓ - Range of 7,1 kN to 470 kN at 6 bar pressure - Unit actuation with n.2 valves EPH-Type e EPH-type TX - In line version - Unit attack to rods or screw (TX version) - Horizontal working position → - Range of 7,1 kN to 470 kN at 6 bar pressure - Unit actuation with n.2 valves EPSB-Type e EPSB-type TX - In line version - Unit attack to rods or screw (TX version) - Sub-vertical working position, stem upward ↑ - Range of 7,1 kN to 470 kN at 6...

Open the catalog to page 6

RMA: Mechanical adjustment version - Suitable for every unit - Mechanical adjustment bottom dead N : Automatic control cycle work version - Suitable for every unit - Unit actuation with n.1 valves HS: High speed version - Suitable for every unit - For high frequencies of cycles - Unit actuation with n.1 or n.2 valves RCP: Pneumatic stroke adjustment version - Suitable for every unit - Single working stroke indirect regulation CP: CS-Type front head version - Suitable for every unit - Interchangeable attack head and attack stem with LDP units mod. CS-Type US-Type - Separated air-oil unit -...

Open the catalog to page 7

TECHNICAL FEATURES The E-Type Press Head is a hydropneumatic unit that exploits the incompressibility of liquids in order to generate high thrusts by using compressed air as its power source - 12 models with approaching stroke - Range of 7 to 470 kN thrusts at 6 bar pressure - Max. Operating pressure is 10 bar - Configurations that enable to deal with any application - Without external oil tank - Approaching cylinder with magnetic piston as standard - Test sheet & user manual attached Model MOUNTING DIMENSIONS MODEL A f7 C f7 d E F H P S

Open the catalog to page 8

TECHNICAL FEATURES The E-Type Press Head is a hydropneumatic unit that exploits the incompressibility of liquids in order to generate high thrusts by using compressed air as its power source - 12 models with approaching stroke - Range of 7 to 470 kN thrusts at 6 bar pressure - Max. Operating pressure is 10 bar - Configurations that enable to deal with any application - Without external oil tank - Approaching cylinder with magnetic piston as standard - Test sheet & user manual attached Model MOUNTING DIMENSIONS MODEL

Open the catalog to page 9

TECHNICAL FEATURES The EP-Type XL Pneumohydraulic Cylinders are hydropneumatic units that exploit the incompressibility of liquids to get high forces, using compressed air as motive fluid - 10 models with approach strokes - Available thrust range from 22 kN to 470 kN at 6 bar pressure - Versions for any conditions of use - Max operating air pressure is 6 or 10 bar - Without external tank - Standard magnetic approach cylinder - Sheet test, Declaration of Incorporation and Instructions supplied with units Model MOUNTING DIMENSIONS

Open the catalog to page 10

TECHNICAL FEATURES The E-Type XL Pneumohydraulic Cylinders are hydropneumatic units suitable for working stroke greater than 30mm, which exploit the incompressibility of liquids to get high forces, using compressed air as motive fluid - 7 models with approach and custom work strokes - Available thrust range from 7 kN to 115 kN at 6 bar pressure - Version with drive rods or screws - Versions for any conditions of use - Max operating air pressure is 6 bar - Without external tank - Standard magnetic approach cylinder - Sheet test, Declaration of Incorporation and Instructions supplied with...

Open the catalog to page 11

TECHNICAL FEATURES - Air-oil unit separated - Available thrust range from 5 kN to 300 kN at 6 bar pressure - Universal working position - Easy Customization - Possibility of pull-type cylinder - Possibility of rod through cylinder - Possibility of oil-oil cylinder - Actuation with n.2 or n.3 valves - Max operating air pressure is 6 bar - With compensation exchanger - Sheet test, Declaration of Incorporation and Instructions supplied with units TECHNICAL FEATURES - In line compact version - Available thrust range from 48 kN to 270 kN at 6 bar pressure - Possibility of use in food industry -...

Open the catalog to page 12

Accessories RMA - MECHANICAL FRONT ADJUSTMENT - Mechanical bottom dead adjustment - Absolute positioning repetitiveness - Intrinsic safety for the fact that there are no moving parts - The force is discharged directly to the unit - Possibility of access to the adjustment near the support plate - Possibility of adjusting by acting from all four sides of the unit - Possibility of locking in position by the two opposite sides - Standard setting 10mm, more adjustment ranges on reques RCP - PNEUMATIC STROKE ADJUSTMENT - Mechanical adjustment stroke of the booster cylinder - Single working stroke...

Open the catalog to page 13All LDP Italia - Thrust Technology srl catalogs and technical brochures

-

Pneumatic Presses LP-Type

2 Pages

-

EPP 125

2 Pages

-

EPI 56

2 Pages

-

E-Type TX

2 Pages

-

EPK 21

2 Pages

-

EPK 12

2 Pages

-

Quality Control System

2 Pages

-

M-TYPE Air-Oil Booster

2 Pages

-

Clinching system

2 Pages

-

KS-Type Press Head

2 Pages

-

SP-TYPE Press Head

2 Pages

-

CP-TYPE Press Head

2 Pages

-

E-TYPE press head

2 Pages