Catalog excerpts

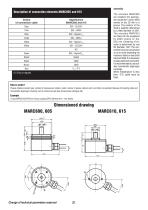

Magnetic absolute encoders MARC605 and 615 MARC605 - synchro flange, external diameter of the shaft 6 mm MARC615 - clamping flange, external diameter of the shaft 6 mm The magnetic single turn absolute rotary encoders type MARC605 and MARC615 working on magnetic Hall Effect principle. The encoder converts rotary motion to electrical signals. Electrical signals provide information of bilateral position of two mechanical parts, angle turn or rotary motion. A typical use is in conjunction with digital control system or drivers for control of the electric motors. Type identification MARC6 X 5 - X / XXXX XX OUTLET PA - Cable 1 m axial PB - Cable 1 m radial (longer cable on request) OUPUT SIGNALS AND NUMBER OF BITS 31 - Parallel TTL binary 9 bits 11 - Serial SSI, diff. gray code into 12 bits 12 - Serial SSI, diff. bin code into 13 bits 21 - Serial SSI, single TTL gray code into 12 bits 22 - Serial SSI, single TTL bin code into 13 bits DIAMETER OF SHAFTS 6 - shaft external diameter 6 mm (standard) 4 - shaft external diameter 4 mm (other diameter on request) SUPPLY vOLTAGE 5 - + 5 V mechanical specification 0 - synchro flange 1 - clamping flange type of encoder 6 - magnetic absolute encoder type MARC6x5 Output signals MARC605 / MARC615 31 - Parallel TTL binary code for encoders with resolution into 9 bits (512 positions). 11 - Serial SSI, differential CLOCK/DATA signals (RS422), gray code into 12 bits (4096 pos.). 12 - Serial SSI, differential CLOCK/DATA signals (RS422), bin code into 13 bits (8192 pos.). 21 - Serial SSI, single TTL CLOCK/DATA signals, gray code into 12 bits (4096 pos.). 22 - Serial SSI, single TTL CLOCK/DATA signals, bin code into 13 bits (8192 pos.). Technical data

Open the catalog to page 1

Description of connection elements MARC605 and 615 The encoders MARC605 are installed into appropriate equipment using 4xM3 screws on dia. 26 mm or a groove. The position of the shaft is explicitly determined by a fitted diameter of 33h7. The encoders MARC61 5 are fixed into the equipment by 2xM3 screws on dia. 22,0 mm. Centering of encoder is determined by mat fits diameter 15h7. The connection has to be constructed so as to avoid exceeding the maximum radial or axial shaft load permitted. It is necessary to keep alignment connection. It is recommended to use suitable homokinetic...

Open the catalog to page 2All LARM a.s. catalogs and technical brochures

-

DRAW-WIRE ENCODER LS501

2 Pages

-

Encoders

7 Pages

-

JIGS & FIXTURES

3 Pages

-

Company presentation

14 Pages