Website:

LARIUS SRL

Website:

LARIUS SRL

Group: SAMOA INDUSTRY

Catalog excerpts

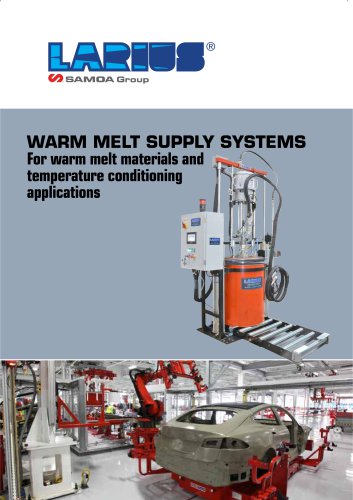

ORDERING INFORMATION Extrusion warm melt supply systems are available with different configurations. To choose the best system configuration it is important to consider: • Extrusion nozzles sizes • Control valves pressure and volume compatibility and their type (manual, automatic, robotic, jet) • Material hoses pressure, volume and chemical compatibility • Pump compatibility with the pumped product WARM - melt systems coding Example: Nova 55:1 warm melt system - Drum weight 200 kg - Two hand control - Roller W - AA - BBB - C - D = W552002R W Warm - melt GHIBLI 26:1 Omega 28:1 OMEGA 40:1 Nova 55:1 200 - 200 kg 30A - 30 kg Double hose Ø 280 mm 30B - 30 kg Single lip 1 One hand control 2 Two hands control WARM MELT SUPPLY SYSTEMS For warm melt materials and temperature conditioning applications 0 Without roller R Roller included Ram and pump air pressure booster + tank 24 l. Operative pressure 2 - 12 bar Ram air pressure booster. Operative pressure 2 - 12 bar Warm melt extrusion gun (Part No. 15027 included) Articulated swivel 3/8" - 6 mm - 250 bar for extrusion gun Nozzle for warm melt applications. Gasket in contact with material in Nylon HIGH PRESSURE HEATED HOSES - 90 °C PART No. HEATED HOSES TEMPERATURE CONTROLLERS PART No. External controller ip65 - 3 users LARIUS S.r.l. VIA ANTONIO STOPPANI, 21 23801 CALOLZIOCORTE (LC) ITALY Tel.: +39 0341 621152 - Fax: + 39 0341 621242 export@larius.com www.larius.com MADE IN ITALY SINCE 1969 NB: Order the temperature controller with its heate

Open the catalog to page 1

TOUCH SCREEN PANEL Temperature management improves the efficiency of high viscosity products processing. PROFESSIONAL EXTRUSION WARM MELT SUPPLY SYSTEMS Warm melt extrusion systems, with reliable performance for all applications that require a constant monitoring of product heating to preserve its chemical characteristics. • Max. operating temperature 90 °C • Max. delivery 12 l/min • Direct suction from 30 l - 200 l drums • Quick container change over • No overheated material • Less product waste • Easy to integrate in all manufacturing lines • Long and reliable product life • User friendly...

Open the catalog to page 2

TOUCH SCREEN PANEL Temperature management improves the efficiency of high viscosity products processing. PROFESSIONAL EXTRUSION WARM MELT SUPPLY SYSTEMS Warm melt extrusion systems, with reliable performance for all applications that require a constant monitoring of product heating to preserve its chemical characteristics. • Max. operating temperature 90 °C • Max. delivery 12 l/min • Direct suction from 30 l - 200 l drums • Quick container change over • No overheated material • Less product waste • Easy to integrate in all manufacturing lines • Long and reliable product life • User friendly...

Open the catalog to page 3

ORDERING INFORMATION Extrusion warm melt supply systems are available with different configurations. To choose the best system configuration it is important to consider: • Extrusion nozzles sizes • Control valves pressure and volume compatibility and their type (manual, automatic, robotic, jet) • Material hoses pressure, volume and chemical compatibility • Pump compatibility with the pumped product WARM - melt systems coding Example: Nova 55:1 warm melt system - Drum weight 200 kg - Two hand control - Roller W - AA - BBB - C - D = W552002R W Warm - melt GHIBLI 26:1 Omega 28:1 OMEGA 40:1...

Open the catalog to page 4All LARIUS SRL catalogs and technical brochures

-

AIRLESS ROAD MARKING MACHINES

24 Pages

-

PAINTING ACCESSORIES

36 Pages

-

INJECTION RESINS PUMPS

6 Pages

-

TEXTURE SPRAYER

4 Pages

-

PNEUMATIC AIRLESS WASH PUMPS

2 Pages

-

LOW PRESSURE PUMPS

2 Pages

-

EXTRUSION ACCESSORIES

12 Pages

-

AIR OPERATED TRANSFER PUMPS

32 Pages

-

pneumatic extrusion pumps

20 Pages