Website:

LANG Technik

Website:

LANG Technik

Catalog excerpts

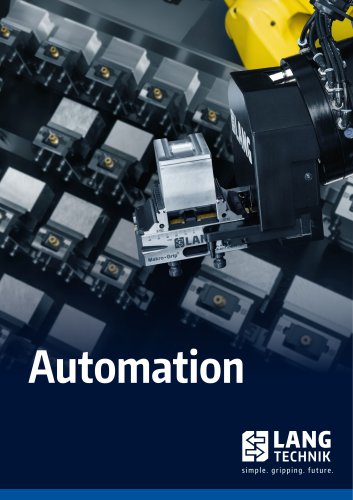

simple. gripping. future. Your expert in workholding and machine tool automation.

Open the catalog to page 1

Dear Customer, In this brochure about our company, we would like to give you an impression of who we are, what we stand for and why we are the right choice if you are looking for a reliable and competent partner for workholding and automation. You will read everything important about the various product groups, their benefits and fields of application. The main focus in this brochure is on zero-point clamping, workholding and automation, our three major product groups. Along with the stamping technology they form a perfectly coordinated, proven package, which is what makes us unique in the...

Open the catalog to page 3

simple. gripping. future. Headquarters: Holzmaden – GERMANY Subsidiary LANG Technovation: Training and Technology Centres: Neuhausen auf den Fildern – GERMANY Seelze near Hannover (from 8/21) GERMANY 140 EMPLOYEES AT FOUR LOCATIONS EXCLUSIVE DISTRIBUTORS WORLDWIDE > 1,000 WORKHOLDING SYSTEMS ARE DISPATCHED EVERY MO

Open the catalog to page 4

TRADITION AND INNOVATION LANG Technik is looking back on almost 40 years of experience in the machining industry. Starting as a subcontractor, we have been developing own products since 1997, always true to the motto "Made in Germany". Since then, numerous patents and pioneering innovations SIMPLE USABILITY – ATTRACTIVELY PRICED have followed. Today our family business is one of the world's market leaders in workholding and automation. SOLUTIONS FOR ANY APPLICATION Companies of all sizes, from 1-man-operation to global players, from various industries trust our vast experience and...

Open the catalog to page 5

Giving every machinin access to innovative an solutions, simplifying th costs and guaranteei

Open the catalog to page 6

g company worldwide d flexible workholding eir processes, reducing ng consistent quality.

Open the catalog to page 7

Our Mission As a pioneer in this industry, we develop and produce integrated solutions in the field of automation, zeropoint clamping and workholing for both ourselves and for all machining industry sectors. ZERO-POINT CLAMPING

Open the catalog to page 8

SECURITY With LANG you always get "The Original" for sure. High-quality and attractively priced. PROXIMITY Our manufacturing processes are at the highest level. With our partners we work at eye level. SUSTAINABILITY We are in the black with green electricity. Our philosophy: Thinking ahead sustainably. SIMPLICITY We make it easy for our customers, not for ourselves. The result: Simple usability, simple handling, simple workflows. INNOVATION We do not need to say much about our work. Because four decades of expertise, many successful patents and our brand speak for themselves.

Open the catalog to page 10

SECURITY PROXIMITY SUSTAINABILITY SIMPLICITY INNOVATION

Open the catalog to page 11

Zero-Point Clamping, Workholding and Automation – all from one source. Automation Zero•Point Clampin

Open the catalog to page 12

A proven and perfectly combined package of workholding, zero-point clamping and automation, along with our unrivaled stamping technology, provides our customers with the necessary requirements to stay efficient and competitive.

Open the catalog to page 13

ZERO-POINT CLAMPING

Open the catalog to page 15

Main product groups: Zero-Point Clamping Flexible, precise and extremely durable. The Quick•Point® Zero-Point Clamping System combines: SET-UP TIME SAVINGS SIMPLE, MECHANICAL OPERATION As an interface between the machine table and clamp- application. It can be used universally in vertical and ing device, Quick•Point is characterised by an enor- horizontal machining centres, on 3- and 5-axis tables mous range of variations and high repeatability. Round, and 4th axis rotary or trunnion systems. Due to its rectangular or square in shape, for single or multiple modularity the system can be...

Open the catalog to page 16

Multiple clamping systems and tombstones Quick•Point® Quick-Tower Tombstone Twin Base Additional components Quick•Point® Automation Zero-Point Device Quick•Point® Quick•Point®

Open the catalog to page 17

Main product groups: Zero-Point Clamping Functional principle of Quick•Point® Zero-Point Plates By design Quick•Point® is a purely mechanical zero-point torque of 30 Nm (60 Nm for 4-fold Grid Plates) results system. A patented rod system inside the plate guaran- in holding forces of 6,000 kg. Due to a small number of tees a repeatability of less than 0.005 mm. Quick•Point® wear-free parts the zero-point system is reliable and plates are actuated by one screw or the Quick-Lock virtually maintenance free. device to ensure simple and easy operation. An act

Open the catalog to page 18

Modular, flexible and always a good fit. its enormous modularity through complementary With nearly 50 different types of zero-point plates and diverse customisation possibilities Quick•Point items, such as risers, tombstones and, in particular, provides a suitable solution for every type of machine receiver plates with which the zero-point grid size can table. On large machine tables a continuous grid can be reduced from 96 mm to 52 in order to use all sizes of be realised using (multi) grid plates in order to make LANG vices flexibly. best use of the available space. Quick•Point unfolds ®

Open the catalog to page 19

Main product groups: Zero-Point Clamping Direct clamping of workpieces and fixtures Quick•Point® clamping studs connect the zero-point vices is possible to benefit from all the advantages of system and LANG workholding devices. They can be the Quick•Point ® zero-point clamping system. The con- also mounted directly to a workpiece in order to clamp nection between clamping studs and zero-point plate it directly without a workholding device. Even the is extremely robust, very precise and can undoubtedly mounting to customers own fixtures or conventional resist even the strongest machining...

Open the catalog to page 20

Increased productivity with multiple clamping systems and tombstones For multi-clamping operations LANG presents various options to automatically increase machine running time and at the same time reduce the amount of tool changes. For horizontal machines the Quick-Tower tombstone is a great choice to clamp up to 32 vices at the same time, whereas the MT3 / MT4 tombstones are generally used in smaller 5-axis machines.

Open the catalog to page 21All LANG Technik catalogs and technical brochures

-

New products - fall 2023

28 Pages

-

Zero point clamping

37 Pages

-

Automation

31 Pages

-

Workholding

63 Pages