Catalog excerpts

Interferometer for the flatness check of lapped and ground parts The SPI interferometers are the right choice for the visual flatness check of lapped or ground surfaces which do not show fringe contrast with an optical flat. The special version SPI xs offers a higher sensitivity compared to the SPI standard version. The SPI uses the principle of grazing incidence of light on the surface and shows light bands of high contrast for rough as well as polished surfaces. For testing, the parts are simply placed on the glass surface on the top side of the SPI. A magnified image of part and fringes is displayed on a monitor. The interpretation of fringes is the same as with an optical flat: straight, parallel and Interferogram of an Al2O3control wheel, which can be saved as a bitmap by the Intdok Software evenly spaced fringes indicate a high degree of flatness. The SPI interferometers can be placed directly in the production area, right beside the lapping or grinding machine. Documentation of flatness is possible with the optional Intdok program or a video printer. Extract of the Evaluation Software Intdok - Presentation of a control wheel overlaid with a horizontal grid Measurement Area (Diameter) 65 mm (other sizes upon request) Flatness of Reference Surface better than 0.15 µm (under constant environmental conditions) LAMTECH Lasermesstechnik GmbH • Nellinger Strasse 20 • 70619 Stuttgart • Germany • Telefon:+49 (0)711 232810 • Fax:+49 (0)711 2361125 • email:info@lamtech.de Data subject to change. April 20

Open the catalog to page 1All Lamtech Lasermesstechnik GmbH catalogs and technical brochures

-

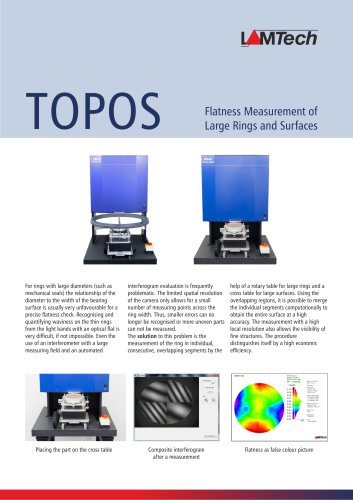

Solution for large surfaces

2 Pages

-

PGI

1 Pages

-

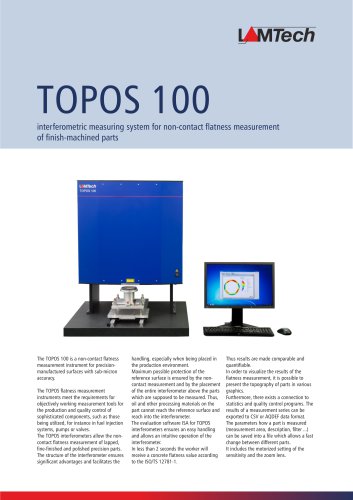

TOPOS 100

2 Pages

-

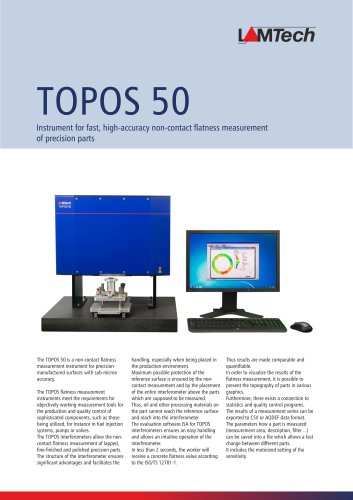

TOPOS 50

2 Pages