Website:

Lamtech Lasermesstechnik GmbH

Website:

Lamtech Lasermesstechnik GmbH

Catalog excerpts

Interferometric measuring systems for the flatness measurement of precision parts TOPOS Flatness Measurement Instrument for the fast, non-contact flatness measurement SPI visual inspection interferometer for the visual flatness check

Open the catalog to page 1

TOPOS flatness measurement instruments allow the noncontact flatness check of lapped, ground as well as polished precision parts. Advantages of the TOPOS flatness measurement instrument: • Maximum protection of the reference surface due to the noncontact measurement which leads to a considerable reduction of maintenance costs • Oil and other processing material cannot reach the reference surface and/or reach into the flatness measurement instrument • The measurement instrument can be placed in the production line, close to the processing machines • the TOPOS instruments are suitable for the...

Open the catalog to page 2

Visual flatness check SPI visual inspection interferometers allow the visual flatness check of lapped, ground as well as polished precision parts. PGI visual inspection interferometers allow the visual flatness check of polished surfaces. Advantages of the visual inspection interferometers: • Broad range of measurable parts: matte as well as polished parts can be measured • Software Intdok allows the documentation and a simpler evaluation Measurement with SPI and PGI: For testing, the parts are simply placed on the glass surface respecively optical flat on the top side of the...

Open the catalog to page 3

Programs for the evaluation and documentation of fringe patterns Evaluation software ISA for TOPOS flatness measurement instruments Advantages of the ISA software: Ÿ Output of concrete flatness values, which make results comparable and quantifiable Ÿ The topography of a part can be displayed in various forms (measuring data sheet, false-color picture, relief image, etc.) Ÿ Connection to statistics and quality control programs: data output of measuring results as series of measurement in CSV or AQDEF data format Evaluation software Intdok for the documentation of fringe patterns of SPI and...

Open the catalog to page 4

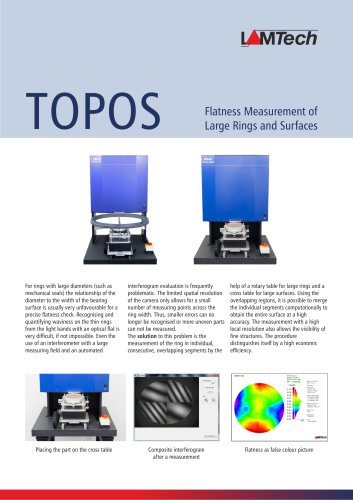

Economic feasibility and technical realisation are a problem for the flatness measurement of large surfaces. Additionally, the lateral resolution of enlarging measuring areas decreases, which limits the applicapility of the measurement process especially when it comes to narrow rings. The solution to this problem is the measurement in individual, consecutive, overlapping segments by the help of a rotary table for large rings and a cross table for large surfaces. The stitching-method combines mathematically single measurements to the total surface. The method distinguishes itself by high...

Open the catalog to page 5

Lasermesstechnik GmbH • implementation of customer-specific software requirements • individual adaption of the devices to production processes • in-house developement and production in Germany updated April 2017, subject to change without notice

Open the catalog to page 6All Lamtech Lasermesstechnik GmbH catalogs and technical brochures

-

Solution for large surfaces

2 Pages

-

PGI

1 Pages

-

SPI

1 Pages

-

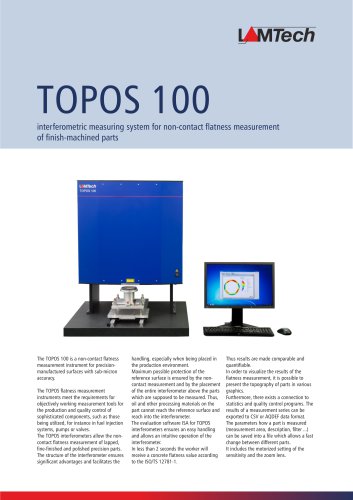

TOPOS 100

2 Pages

-

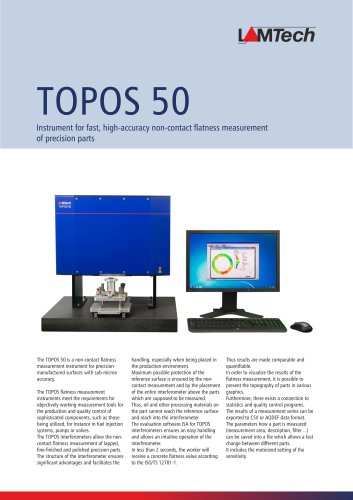

TOPOS 50

2 Pages