Website:

Labthink Instruments Co., Ltd.

Website:

Labthink Instruments Co., Ltd.

Group: Labthink

Catalog excerpts

The Temperature Factor and New Trends for the Sealing Performance Test of Flexible Packages Abstract: this article introduces the sealing performance test methods of flexible packages and the critical factors. Meanwhile, a detailed introduction of new test technological progress and applications is put forward as per market demands. Key Words: leakage, sealing, package, storage, broken package There are many indexes to be considered when choosing flexible packaging forms and materials. For example, the barrier property of package against light and gas, the volume of headspace, the costs for package, transportation and storage, the convenience of application and the environmental- friendly properties of the materials, etc., should all be considered. The comprehensive evaluation of those indexes is the foundation for the choice of the best packages. However, the sealing performance tests, or such tests with specimens that have undergone simulation tests as aging tests and vibration tests, etc., is the veto of flexible package evaluation. Therefore, sealing performance is the premise for the realization of package functions. It’s also the comprehensive embodiment of matching performance between the flexible packaging materials themselves, and with the mechanical, thermological and optical properties of the choiced packaging forms. The inferior sealing performance packages would lead to content deterioration owing to gas or liquid transmission through the packages, and would probably lead to pollution to the environment and the surrounding subjects. As to functional packages, the leakage would lead to failure of the packaging functions and losses to the users. 1Sealing Performance Testing Methods for Flexible Packages There are commonly two flexible sealing performance testing methods, namely, the positive pressure method and the negative pressure method. The positive pressure method fills the specimen with gas to increase the inner pressure, and determines leakage according to the changes of the inner pressures. The negative pressure method puts the specimen into the water of the testing cell, and produces a pressure difference inside and outside the specimen by vacuum pumping the cell. Observe gas leakage or water permeance of the specimen so as to determine whether the sealing flaw really exists. Sealing performance test data is the important basis for test condition setup and result evaluation of the simulation tests, such as product storage, stack and vibration, etc. Comparing with other test items, the most outstanding characteristic of sealing performance test is the varied kinds of test subjects that it applies to. The test subjects of other tests are usually singular. For example, the tensile test can only test films and sheets, the flex durability test can only test films, and headspace test can only test packages. Yet, sealing performance tests can not only test various packages, but the semi-finished packages as well. The specimen can be a finished package, or a sampling from any stage of the logistic process. Meanwhile, with accessories, more subjects with more sizes and shapes can be tested. 2. The Influencing Factors for Flexible Package Sealing Performance Test The sealing performance test is the comprehensive embodiment of matching performance between the flexible packaging materials themselves, and with the mechanical, thermological and optical properties of the choiced packaging forms. The sealing performance of flexible packages is directly influenced by external forces, temperature changes and ray radiation, etc. Many factors can not influence the packages directly, but can lead to decrement of material strength and heat-seal layer fastness, as well as the exudation of additive to the flexible packaging materials, all of which come to affect the sealing performance of flexible packages. However, it should www.labthinkinternational.com.cn

Open the catalog to page 1

be emphasized that different influencing factors would result in different influences, and if the actual influencing result of each factor is to be analyzed, the workload and costs would be greatly increased. Therefore, it is not realistic to take all the influencing factors into consideration. Only those influential ones should be emphasized, or regarded as one of the test conditions. Otherwise, the practicability of the test results would be limited. Previous tests indicate that temperature is the key factor for sealing performance of flexible packages during storage and transportation....

Open the catalog to page 2

Now, the positive pressure method instruments can accurately obtain max. burst resistance pressure of flexible packages, as well as the max. lasting time before breakage under certain pressure. Besides, the sealing performance tests of specific parts can be realized with the help of fixtures, which can effectively improve the practicability of the test data and analyze the vulnerable segments in the package structure so as to provide basis for structural improvement, material selection and more accurate critical breakage conditions for stack, storage, transportation, impact and many other...

Open the catalog to page 3All Labthink Instruments Co. catalogs and technical brochures

-

C630H Heat Seal Tester

3 Pages

-

C610M Auto Tensile Tester

3 Pages

-

Heat seal testing instrument

3 Pages

-

Paper Board Thickness Tester

4 Pages

-

Film Thickness Meter

4 Pages

-

C632B Hot Tack Tester

3 Pages

-

C632M Hot tack Tester

3 Pages

-

Tensile Testing Device

3 Pages

-

Peel Force Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

"ELEMENDORF" test device

2 Pages

-

C680M Tearing Tester

2 Pages

-

C650H Headspace Gas Analyzer

2 Pages

-

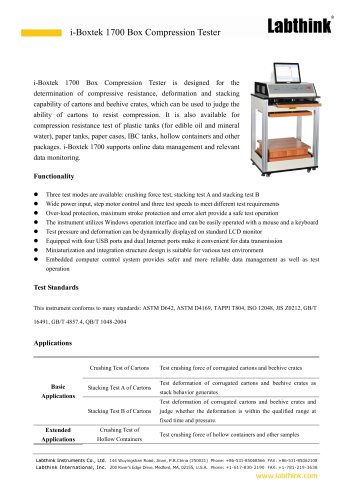

Box Compression Tester

2 Pages

-

Peel Force Tester

3 Pages

-

Pull Off Adhesion Tester

3 Pages

-

Torque Measuring Devices

3 Pages

-

Bottle Torque Tester

3 Pages

-

Packaging Burst Tester

3 Pages

-

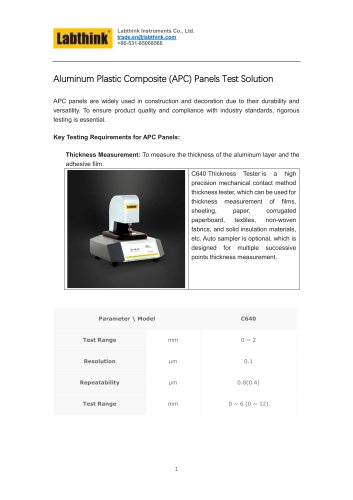

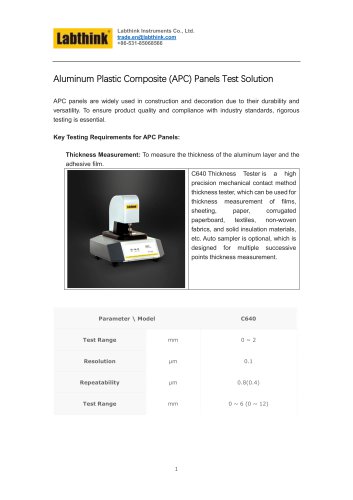

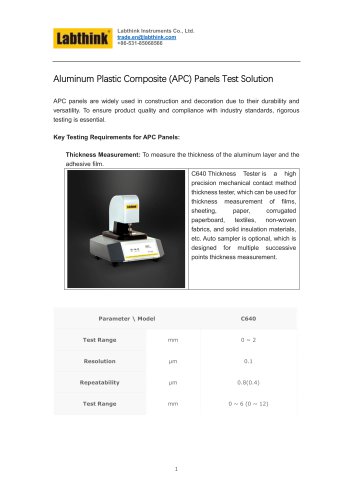

PARAM C640 Thickness Tester

4 Pages

-

Torque Strength Measuring

3 Pages

-

Bottle Leak Tester Machine

3 Pages

-

Oxygen Transmission Tester

4 Pages

-

C612M Digital Torque Tester

3 Pages

-

Bag COF Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Sandwich Bag COF Tester

2 Pages

-

Textile Thickness Gauge

4 Pages

-

C680M Tearing Tester

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Heat Shrink Tester

2 Pages

-

Tensile Testing Device

3 Pages

-

MAP Packaging Burst Tester

3 Pages

-

MAP Packaging Leak Tester

3 Pages

-

Lug Cap Torque Tester

3 Pages

-

Motorized Pull Test Machine

3 Pages

-

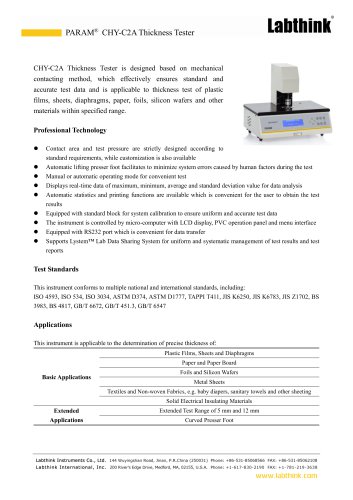

CHY-C2A Thickness Tester

2 Pages

-

Heat Seal Tester

3 Pages

-

Roll Tack Tester

1 Pages

-

Spot Thickness Measurement

4 Pages

-

Adhesive Tack Tester

2 Pages

-

Vacuum Bag Leak Tester

3 Pages

-

Micron Film Thickness Gauge

4 Pages

-

Spot thickness measurement

4 Pages

-

Automatic Tube Leak Tester

2 Pages

-

Burst Test Equipment

3 Pages

-

Elongation Tester

3 Pages

-

Box Compression Test Machine

2 Pages

-

Adhesion Tester for Sticker

2 Pages

-

Ink Rub Lab Equipment

2 Pages

-

Friction Testing Machine

3 Pages

-

Fabric Thickness Measurement

4 Pages

-

Snack Bag Leak Detector

3 Pages

-

Carton Stacking Test Machine

2 Pages

-

Sheet Metal Thickness Gauge

4 Pages

-

Residual oxygen level tester

2 Pages

-

Vacuum Tube Leak Tester

3 Pages

-

leak detector for packaging

3 Pages

-

bottle torque tester machine

3 Pages

-

micrometer per ASTM D374

4 Pages

-

rub tester for wine labels

2 Pages

-

LAB THICNESS TESTER

3 Pages

-

Peel tester for 180 Degree

5 Pages

-

Ball tack tester

5 Pages

-

table top thickness gauge

12 Pages

-

Tabletop sealing machine

14 Pages

-

Film Friction Tester

2 Pages

-

Head space Oxygen Analyser

2 Pages

-

90 degree peel test Device

3 Pages

-

C681M Flex Durability Tester

2 Pages

-

C650M Headspace Gas Analyzer

2 Pages

-

C650B Headspace Gas Analyzer

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

C620H Friction

3 Pages

-

C611M Box Compression Tester

2 Pages

-

C611B Box Compression Tester

2 Pages

-

C610M Auto Tensile Tester

3 Pages

-

C610H Auto Tensile Tester

3 Pages

-

Handheld Headspace Analyzer

2 Pages

-

Cap Torque Machine

5 Pages

-

Oxygen Permeation Analyser

3 Pages

-

Oxygen Permeation Apparatus

3 Pages

-

Papier Abrieb-Testmaschine

1 Pages

-

Bottle Cap Leak Tester

4 Pages

-

torque meter for PET Bottles

3 Pages

-

box compression device

5 Pages

-

BLJ-02 Disk Stripping Tester

2 Pages

-

RT-01 Rub Tester

2 Pages

-

MCJ-01A Rub Tester

2 Pages

-

Floor Slip Resistance Tester

5 Pages

-

Leak Tester

3 Pages

-

Consultative Testing Service

4 Pages

-

BOPP Tape Shear Tester

3 Pages

-

Bell Jar leak tester

2 Pages

-

COF testing of Polymer Films

2 Pages

-

labthink MFY-01 Leak Tester

3 Pages

-

Heat Sealing Property Tester

1 Pages

-

Tablet Leak Test Apparatus

5 Pages

-

Precise Tape Peeling Tester

5 Pages

-

BOPP Film Thickness Meter

2 Pages

-

Package Headspace Analyzer

5 Pages

-

electrical torque meter

5 Pages

-

tape peeling tester

5 Pages

-

tensile testing instrument

5 Pages

-

gas leakage detector LSSD-01

5 Pages

-

XLW (G6) Auto Tensile Tester

3 Pages

-

XLW (M) Auto Tensile Tester

3 Pages

-

XLW (B) Auto Tensile Tester

2 Pages

-

XLW Auto Tensile Tester

3 Pages

-

CHY-C2 Thickness Tester

2 Pages

-

CHY-CA Thickness Tester

2 Pages

-

XLW (PC) Auto Tensile Tester

3 Pages

-

Plastic Film Thickness Test

2 Pages

-

Tensile Strength Machine

5 Pages

-

fogging testing machine

5 Pages

-

heat sealing testing machine

5 Pages

-

shrinkage testing machine

5 Pages

-

torque testing machine

5 Pages

-

Medical Package leak Tester

5 Pages

-

Food Package leak Tester

5 Pages

-

ink rubbing test machine

5 Pages

-

rolling ball tack tester

5 Pages

-

Glebo flex tester

5 Pages

-

hot tack tester

5 Pages

-

tape peel force tester

5 Pages

-

Rolling Ball Tester

5 Pages

-

permeability apparatus

5 Pages

-

CHY-CB Thickness Tester

2 Pages

-

Heat Shrinkage Force Tester

5 Pages

-

XLW (EC) Auto Tensile Tester

3 Pages

-

gas leakage detector MFY-01

5 Pages

-

materials Flex tester

5 Pages

-

oxygen headspace analyzer

5 Pages

-

cap torque testing machine

5 Pages

-

Lasting Ahesion Tester

5 Pages

-

Peeling strength tester

5 Pages

-

Torque Measurement Equipment

2 Pages

-

Heat Sealing Test machine

1 Pages

-

FDI-01

5 Pages

-

Leakage Detector

5 Pages

-

Rolling Ball Adhesion Tester

1 Pages

-

film thickness gauge

5 Pages

-

rub testing machine

5 Pages

-

air leakage tester

5 Pages

-

vacuum leak detector

4 Pages

-

plastic film testing machine

3 Pages

-

carton compression test

5 Pages

-

plastic cap torque tester

5 Pages

-

manual torque tester

1 Pages

-

opening torque tester

2 Pages

-

Oxygen headspace Analyzer

2 Pages

-

Permeability Test System

2 Pages

-

DIN 75201

2 Pages

-

Tensile strength test bench

5 Pages

-

impact testing equipments

2 Pages

-

thickness gauge

5 Pages

-

vacuum leak testing machine

2 Pages

-

paper thickness measurement

5 Pages

-

FDT-02 Gelbo Flex Tester

5 Pages

-

Friction Coefficient Tester

5 Pages

-

Drop Ball Impact Tester

5 Pages

-

Dealers wanted

1 Pages

-

Abrasion Resistance Tester

2 Pages

-

HST-H3 Heat Sealing Machine

1 Pages

-

FPT-F1 Friction/ Peel Tester

2 Pages

-

FT-F1 Fogging Tester

2 Pages

-

Material Testing Equipment

2 Pages

-

Packaging Testing

2 Pages

-

Abrasion Test

2 Pages

-

Torque Meter

2 Pages

-

pendulum impact tester

2 Pages

-

Oxygen Transmission Analyzer

2 Pages

-

Friction Tester

2 Pages

-

Leak Detector

2 Pages

-

Analyzer for MAP

2 Pages

-

Adhesive Strength Tester

1 Pages

-

O2 & CO2 Analyzer

1 Pages

-

Gas Permeability Tester

2 Pages

-

Heat Thermal Shrink Tester

1 Pages

-

Paper Air Resistance Tester

1 Pages

-

Lasting Adhesive Tester

2 Pages

-

Cap Torque Tester

3 Pages

-

Lasting Adhesion Tester

2 Pages

-

Gradient Heat Seal Tester

4 Pages

-

Head space gas Analysis

4 Pages

-

Headspace Gas Analyser

3 Pages

-

Headspace Gas Analyzer

3 Pages

-

Material Tensile Tester

5 Pages

-

Ink Rub Tester

2 Pages

-

medical packaging tester

3 Pages

-

Hot Tack Tester (Data Sheet)

2 Pages

-

Heat Sealing tester

2 Pages

-

Evaporation Residue Tester

3 Pages

-

Blister Package testing

3 Pages

-

Gas Permeability Analyzer

3 Pages

-

Tensile Testing Machine

2 Pages

-

package integrity tester

2 Pages

-

Oxygen permeation Analyzer

2 Pages

-

Drop Impact Tester

2 Pages

-

Torque tester

2 Pages

-

Compression Testing Machine

2 Pages

-

Material Testing Machine

3 Pages

-

Shrink Film testing

2 Pages

-

fogging tester

2 Pages

-

Impact tester

2 Pages

-

Quality Concerns of Doypacks

2 Pages

-

Material Testing

2 Pages

-

laboratory heat sealer

2 Pages

-

Automated Heat Sealer

1 Pages

-

analog thickness gauge

1 Pages

-

Residual Gas Analyzer

1 Pages

-

digital torque gauge

1 Pages

-

packaging Industry

2 Pages

-

Metrology and Test Equipment

2 Pages

-

Tensile Tester

2 Pages

-

material moisture monitor

2 Pages

-

Gas Analyzer

2 Pages

-

Headspace Gas Analyzer

1 Pages

-

FRICTION/PEEL TESTER

1 Pages

-

HOLDING TACK TESTER

1 Pages

-

ROLLING BALL TESTER

1 Pages

-

BOX COMPRESSION TESTER

1 Pages

-

INK RUB TESTER

1 Pages

-

FOGGING TESTER

2 Pages

-

Film Shrinkage Tester

1 Pages

-

Film Pendulum Impact Tester

1 Pages

-

FALLING DART IMPACT TESTER

1 Pages

-

THICKNESS TESTER

1 Pages

-

TOQUE TESTER

1 Pages

-

Tearing Tester

1 Pages

-

Gas Permeability Tester

1 Pages

-

Oxygen Permeability Tester

2 Pages

Archived catalogs

-

Leak Tester

2 Pages