Website:

Labthink Instruments Co., Ltd.

Website:

Labthink Instruments Co., Ltd.

Group: Labthink

Catalog excerpts

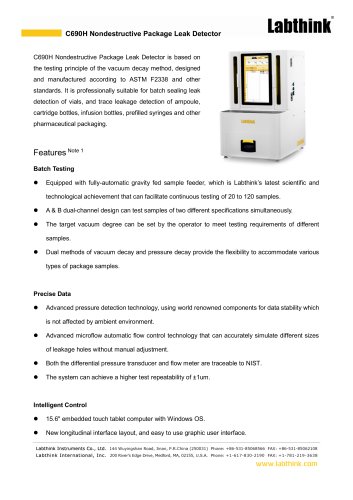

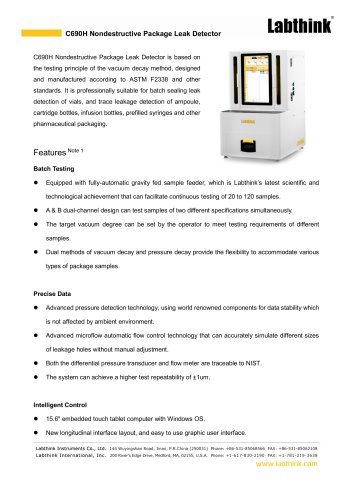

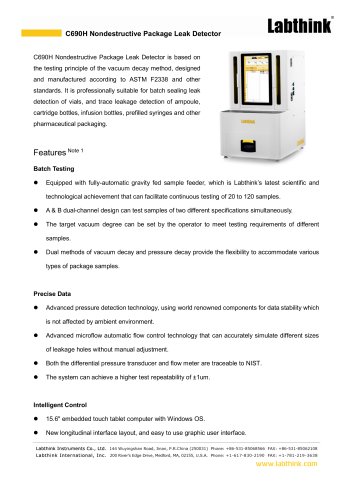

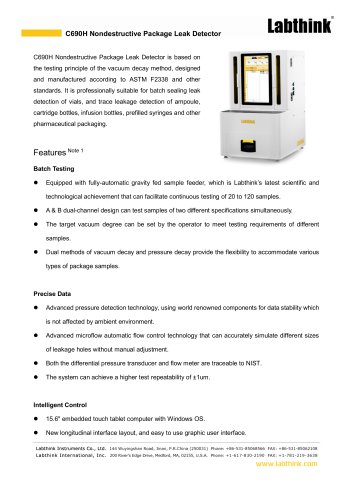

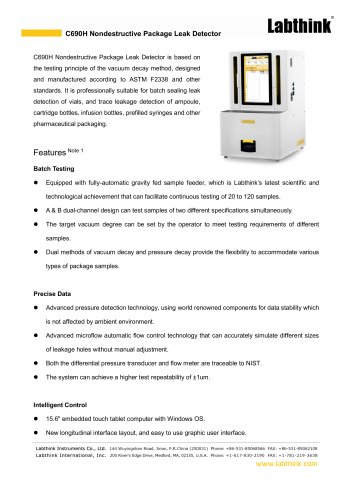

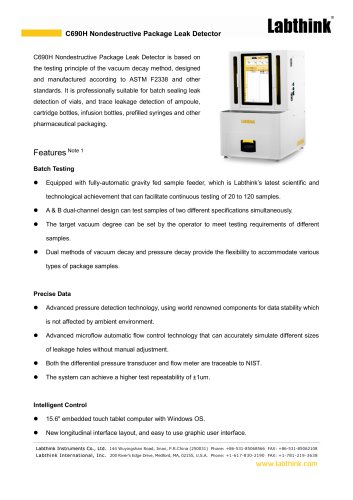

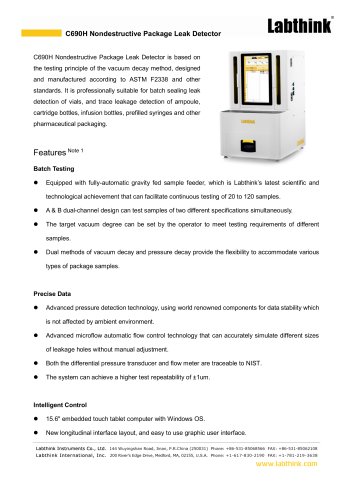

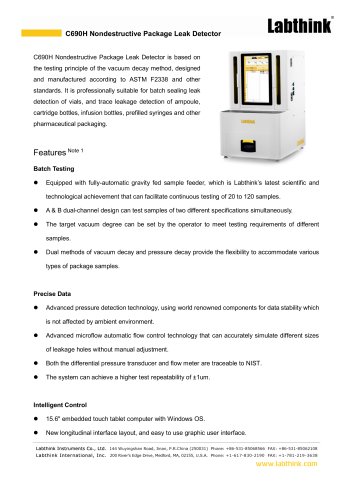

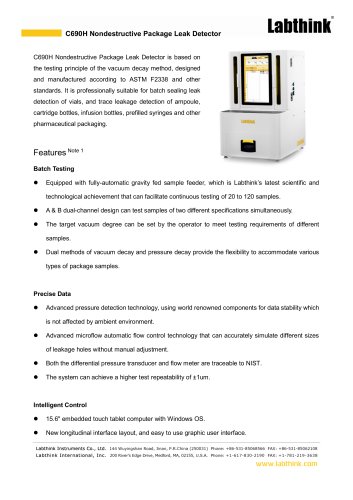

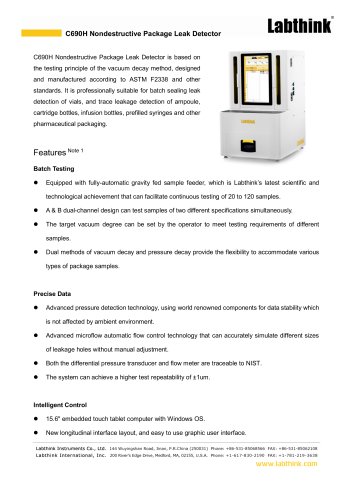

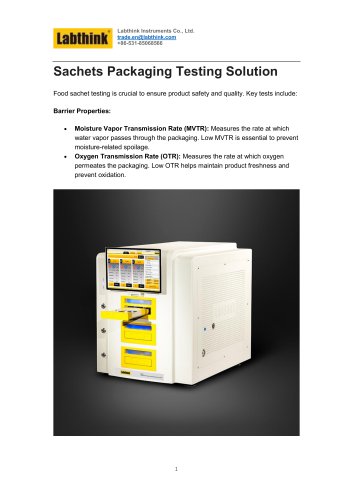

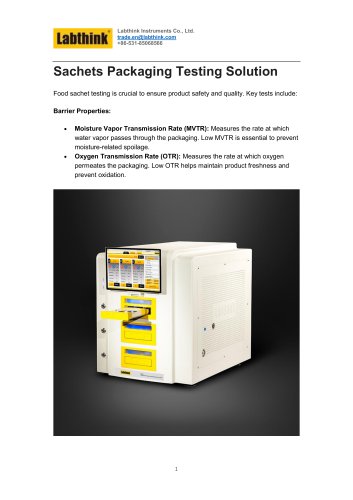

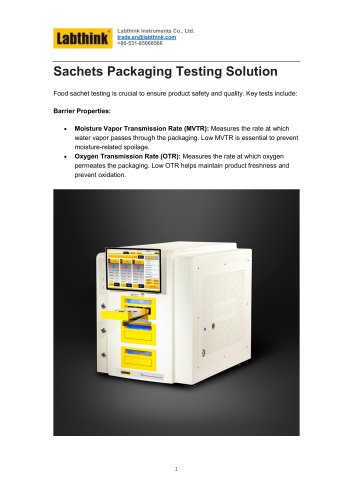

C690H Nondestructive Package Leak Detector C690H Nondestructive Package Leak Detector is based on the testing principle of the vacuum decay method, designed and manufactured according to ASTM F2338 and other standards. It is professionally suitable for batch sealing leak detection of vials, and trace leakage detection of ampoule, cartridge bottles, infusion bottles, prefilled syringes and other pharmaceutical packaging. Features Note 1 Batch Testing Equipped with fully-automatic gravity fed sample feeder, which is Labthink’s latest scientific and technological achievement that can facilitate continuous testing of 20 to 120 samples. A & B dual-channel design can test samples of two different specifications simultaneously. The target vacuum degree can be set by the operator to meet testing requirements of different samples. Dual methods of vacuum decay and pressure decay provide the flexibility to accommodate various types of package samples. Advanced pressure detection technology, using world renowned components for data stability which is not affected by ambient environment. Advanced microflow automatic flow control technology that can accurately simulate different sizes of leakage holes without manual adjustment. Both the differential pressure transducer and flow meter are traceable to NIST. The system can achieve a higher test repeatability of ±1um. 15.6" embedded touch tablet computer with Windows OS. New longitudinal interface layout, and easy to use gra

Open the catalog to page 1

Automatic alarm, automatic capture, automatic collection of unqualified samples. The pressure curve is displayed in real time, and the test results are counted automatically. Leakage rates are calculated automatically. The system is equipped with various sensors as intelligent reminders for safer operation and control. Universal printer can be connected for test results output. The system features embedded with USB and network ports to facilitate the external access and data transmission of the system, which can be upgraded remotely. Verified by compensation and calibration methods. The...

Open the catalog to page 2

Injection bottles Various injection bottles sealing test. Technical Parameters Table 1: Test Parameters Note 2 Parameter \ Model Testing Range um(Reference aperture size USP1207) Detection Lower Limit Pressure Range Extended Functions GMP computer system requirements Table 2: Technical Specifications Testing Cell Sample Feeder Sample Size Sample Quantity Compressed Air (Gas source is provided by the user) Port Size Table 3: Product Configuration Standard Configuration Mainframe, embedded tablet computer, software, flow meter, European vacuum pump, Φ6 mm polyurethane tube Test cell and...

Open the catalog to page 3

designed according to sample specifications Optional Parts GMP computer system requirements, 21 CFR Part11, air compressor , IQ/OQ/PQ documents Note 1: The described product characteristics are subject to the specific annotation of the "Technical Parameters" table. Note 2: The parameters in the table are measured in the Labthink laboratory by professional operators according to the requirements and conditions of the relevant laboratory environmental standards. Note 3: Group C test cell can be customized for samples beyond the "Sample Size", but the lower detection limit and test range will...

Open the catalog to page 4All Labthink Instruments Co. catalogs and technical brochures

-

C630H Heat Seal Tester

3 Pages

-

C610M Auto Tensile Tester

3 Pages

-

Heat seal testing instrument

3 Pages

-

Paper Board Thickness Tester

4 Pages

-

Film Thickness Meter

4 Pages

-

C632B Hot Tack Tester

3 Pages

-

C632M Hot tack Tester

3 Pages

-

Tensile Testing Device

3 Pages

-

Peel Force Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

"ELEMENDORF" test device

2 Pages

-

C680M Tearing Tester

2 Pages

-

C650H Headspace Gas Analyzer

2 Pages

-

Box Compression Tester

2 Pages

-

Peel Force Tester

3 Pages

-

Pull Off Adhesion Tester

3 Pages

-

Torque Measuring Devices

3 Pages

-

Bottle Torque Tester

3 Pages

-

Packaging Burst Tester

3 Pages

-

PARAM C640 Thickness Tester

4 Pages

-

Torque Strength Measuring

3 Pages

-

Bottle Leak Tester Machine

3 Pages

-

Oxygen Transmission Tester

4 Pages

-

C612M Digital Torque Tester

3 Pages

-

Bag COF Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Sandwich Bag COF Tester

2 Pages

-

Textile Thickness Gauge

4 Pages

-

C680M Tearing Tester

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Heat Shrink Tester

2 Pages

-

Tensile Testing Device

3 Pages

-

MAP Packaging Burst Tester

3 Pages

-

MAP Packaging Leak Tester

3 Pages

-

Lug Cap Torque Tester

3 Pages

-

Motorized Pull Test Machine

3 Pages

-

CHY-C2A Thickness Tester

2 Pages

-

Heat Seal Tester

3 Pages

-

Roll Tack Tester

1 Pages

-

Spot Thickness Measurement

4 Pages

-

Adhesive Tack Tester

2 Pages

-

Vacuum Bag Leak Tester

3 Pages

-

Micron Film Thickness Gauge

4 Pages

-

Spot thickness measurement

4 Pages

-

Automatic Tube Leak Tester

2 Pages

-

Burst Test Equipment

3 Pages

-

Elongation Tester

3 Pages

-

Box Compression Test Machine

2 Pages

-

Adhesion Tester for Sticker

2 Pages

-

Ink Rub Lab Equipment

2 Pages

-

Friction Testing Machine

3 Pages

-

Fabric Thickness Measurement

4 Pages

-

Snack Bag Leak Detector

3 Pages

-

Carton Stacking Test Machine

2 Pages

-

Sheet Metal Thickness Gauge

4 Pages

-

Residual oxygen level tester

2 Pages

-

Vacuum Tube Leak Tester

3 Pages

-

leak detector for packaging

3 Pages

-

bottle torque tester machine

3 Pages

-

micrometer per ASTM D374

4 Pages

-

rub tester for wine labels

2 Pages

-

LAB THICNESS TESTER

3 Pages

-

Peel tester for 180 Degree

5 Pages

-

Ball tack tester

5 Pages

-

table top thickness gauge

12 Pages

-

Tabletop sealing machine

14 Pages

-

Film Friction Tester

2 Pages

-

Head space Oxygen Analyser

2 Pages

-

90 degree peel test Device

3 Pages

-

C681M Flex Durability Tester

2 Pages

-

C650M Headspace Gas Analyzer

2 Pages

-

C650B Headspace Gas Analyzer

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

C620H Friction

3 Pages

-

C611M Box Compression Tester

2 Pages

-

C611B Box Compression Tester

2 Pages

-

C610M Auto Tensile Tester

3 Pages

-

C610H Auto Tensile Tester

3 Pages

-

Handheld Headspace Analyzer

2 Pages

-

Cap Torque Machine

5 Pages

-

Oxygen Permeation Analyser

3 Pages

-

Oxygen Permeation Apparatus

3 Pages

-

Papier Abrieb-Testmaschine

1 Pages

-

Bottle Cap Leak Tester

4 Pages

-

torque meter for PET Bottles

3 Pages

-

box compression device

5 Pages

-

BLJ-02 Disk Stripping Tester

2 Pages

-

RT-01 Rub Tester

2 Pages

-

MCJ-01A Rub Tester

2 Pages

-

Floor Slip Resistance Tester

5 Pages

-

Leak Tester

3 Pages

-

Consultative Testing Service

4 Pages

-

BOPP Tape Shear Tester

3 Pages

-

Bell Jar leak tester

2 Pages

-

COF testing of Polymer Films

2 Pages

-

labthink MFY-01 Leak Tester

3 Pages

-

Heat Sealing Property Tester

1 Pages

-

Tablet Leak Test Apparatus

5 Pages

-

Precise Tape Peeling Tester

5 Pages

-

BOPP Film Thickness Meter

2 Pages

-

Package Headspace Analyzer

5 Pages

-

electrical torque meter

5 Pages

-

tape peeling tester

5 Pages

-

tensile testing instrument

5 Pages

-

gas leakage detector LSSD-01

5 Pages

-

XLW (G6) Auto Tensile Tester

3 Pages

-

XLW (M) Auto Tensile Tester

3 Pages

-

XLW (B) Auto Tensile Tester

2 Pages

-

XLW Auto Tensile Tester

3 Pages

-

CHY-C2 Thickness Tester

2 Pages

-

CHY-CA Thickness Tester

2 Pages

-

XLW (PC) Auto Tensile Tester

3 Pages

-

Plastic Film Thickness Test

2 Pages

-

Tensile Strength Machine

5 Pages

-

fogging testing machine

5 Pages

-

heat sealing testing machine

5 Pages

-

shrinkage testing machine

5 Pages

-

torque testing machine

5 Pages

-

Medical Package leak Tester

5 Pages

-

Food Package leak Tester

5 Pages

-

ink rubbing test machine

5 Pages

-

rolling ball tack tester

5 Pages

-

Glebo flex tester

5 Pages

-

hot tack tester

5 Pages

-

tape peel force tester

5 Pages

-

Rolling Ball Tester

5 Pages

-

permeability apparatus

5 Pages

-

CHY-CB Thickness Tester

2 Pages

-

Heat Shrinkage Force Tester

5 Pages

-

XLW (EC) Auto Tensile Tester

3 Pages

-

gas leakage detector MFY-01

5 Pages

-

materials Flex tester

5 Pages

-

oxygen headspace analyzer

5 Pages

-

cap torque testing machine

5 Pages

-

Lasting Ahesion Tester

5 Pages

-

Peeling strength tester

5 Pages

-

Torque Measurement Equipment

2 Pages

-

Heat Sealing Test machine

1 Pages

-

FDI-01

5 Pages

-

Leakage Detector

5 Pages

-

Rolling Ball Adhesion Tester

1 Pages

-

film thickness gauge

5 Pages

-

rub testing machine

5 Pages

-

air leakage tester

5 Pages

-

vacuum leak detector

4 Pages

-

plastic film testing machine

3 Pages

-

carton compression test

5 Pages

-

plastic cap torque tester

5 Pages

-

manual torque tester

1 Pages

-

opening torque tester

2 Pages

-

Oxygen headspace Analyzer

2 Pages

-

Permeability Test System

2 Pages

-

DIN 75201

2 Pages

-

Tensile strength test bench

5 Pages

-

impact testing equipments

2 Pages

-

thickness gauge

5 Pages

-

vacuum leak testing machine

2 Pages

-

paper thickness measurement

5 Pages

-

FDT-02 Gelbo Flex Tester

5 Pages

-

Friction Coefficient Tester

5 Pages

-

Drop Ball Impact Tester

5 Pages

-

Dealers wanted

1 Pages

-

Abrasion Resistance Tester

2 Pages

-

HST-H3 Heat Sealing Machine

1 Pages

-

FPT-F1 Friction/ Peel Tester

2 Pages

-

FT-F1 Fogging Tester

2 Pages

-

Material Testing Equipment

2 Pages

-

Packaging Testing

2 Pages

-

Abrasion Test

2 Pages

-

Torque Meter

2 Pages

-

pendulum impact tester

2 Pages

-

Oxygen Transmission Analyzer

2 Pages

-

Friction Tester

2 Pages

-

Leak Detector

2 Pages

-

Analyzer for MAP

2 Pages

-

Adhesive Strength Tester

1 Pages

-

O2 & CO2 Analyzer

1 Pages

-

Gas Permeability Tester

2 Pages

-

Heat Thermal Shrink Tester

1 Pages

-

Paper Air Resistance Tester

1 Pages

-

Lasting Adhesive Tester

2 Pages

-

Cap Torque Tester

3 Pages

-

Lasting Adhesion Tester

2 Pages

-

Gradient Heat Seal Tester

4 Pages

-

Head space gas Analysis

4 Pages

-

Headspace Gas Analyser

3 Pages

-

Headspace Gas Analyzer

3 Pages

-

Material Tensile Tester

5 Pages

-

Ink Rub Tester

2 Pages

-

medical packaging tester

3 Pages

-

Hot Tack Tester (Data Sheet)

2 Pages

-

Heat Sealing tester

2 Pages

-

Evaporation Residue Tester

3 Pages

-

Blister Package testing

3 Pages

-

Gas Permeability Analyzer

3 Pages

-

Tensile Testing Machine

2 Pages

-

package integrity tester

2 Pages

-

Oxygen permeation Analyzer

2 Pages

-

Drop Impact Tester

2 Pages

-

Torque tester

2 Pages

-

Compression Testing Machine

2 Pages

-

Material Testing Machine

3 Pages

-

Shrink Film testing

2 Pages

-

fogging tester

2 Pages

-

Impact tester

2 Pages

-

Quality Concerns of Doypacks

2 Pages

-

Material Testing

2 Pages

-

laboratory heat sealer

2 Pages

-

Automated Heat Sealer

1 Pages

-

analog thickness gauge

1 Pages

-

Residual Gas Analyzer

1 Pages

-

digital torque gauge

1 Pages

-

packaging Industry

2 Pages

-

Metrology and Test Equipment

2 Pages

-

Tensile Tester

2 Pages

-

material moisture monitor

2 Pages

-

Gas Analyzer

2 Pages

-

Headspace Gas Analyzer

1 Pages

-

FRICTION/PEEL TESTER

1 Pages

-

HOLDING TACK TESTER

1 Pages

-

ROLLING BALL TESTER

1 Pages

-

BOX COMPRESSION TESTER

1 Pages

-

INK RUB TESTER

1 Pages

-

FOGGING TESTER

2 Pages

-

Film Shrinkage Tester

1 Pages

-

Film Pendulum Impact Tester

1 Pages

-

FALLING DART IMPACT TESTER

1 Pages

-

THICKNESS TESTER

1 Pages

-

TOQUE TESTER

1 Pages

-

Tearing Tester

1 Pages

-

Gas Permeability Tester

1 Pages

-

Oxygen Permeability Tester

2 Pages

Archived catalogs

-

Leak Tester

2 Pages