Website:

Labthink Instruments Co., Ltd.

Website:

Labthink Instruments Co., Ltd.

Group: Labthink

Catalog excerpts

PARAM® XLW (G6) Auto Tensile Tester Professional Technology Better than 0.5% of reading value effectively ensures accurate test results Multiple testing modes are available, including tensile strength, deformation, peeling and tearing, etc. Stress at defined elongation, elastic modulus and stress and strain etc. could be analyzed 1200mm extra-long stroke satisfies the test needs of various materials with extreme deformation rate 6 working stations and pneumatic specimen clamping facilitate to test multiple specimens simultaneously Different test range of load cells and 6 distinct test speeds to meet different test requirements The instrument is controlled by computer, with PVC operation panel and membrane

Open the catalog to page 1

switch which is convenient for instrument operation Intelligent designs of over-travel protection, overload protect, automatic position reset and intelligent error alerts for safe test operation Professional operating software support statistical analysis of group specimens, superposition analysis of test curves, maximum, minimum, average and standard deviation of test results Support zoom-in and zoom-out of test curve and vernier indication of test results Lab Data Sharing System for uniform and systematic management of test results and test reports Applications This instrument is equipped...

Open the catalog to page 2

Caps Heatseal Strength Test Rubber Closures Hair 90 Degree Peel Heatseal Films Sealing Bags Membranes 180 Degree Peel Release Paper 20 Degree Peel Test Tear Test Unwrapping Force Trouser Method Eccentric Grips Floating Rollers Japanese British Sample Grips Test Principle The pre-conditioned specimen is mounted between two grips, which move in relative direction during the test. The signals of force and displacement changes are separately recorded by the load cell fixed on the driven grip and embedded displacement transducer. The tensile strength, tear strength and elongation rate can be...

Open the catalog to page 3

Test Range Accuracy 0.5% of reading value Specimen Width 30 mm ( Standard Grip ) Sample Clamp Pneumatic Sample Clamp Port Size Instrument Size Power Supply Standard Mainframe, Universal Grips, Professional Software, Communication Configurations Cable< and Calibration Cable Optional Parts Standard Pressure Roller, Test Plate, Sample Cutter, and Customized 1. The port of gas supply is <t>6 mm PU Tubing. 2. Customers will need to prepare for gas supply.

Open the catalog to page 4All Labthink Instruments Co. catalogs and technical brochures

-

C630H Heat Seal Tester

3 Pages

-

C610M Auto Tensile Tester

3 Pages

-

Heat seal testing instrument

3 Pages

-

Paper Board Thickness Tester

4 Pages

-

Film Thickness Meter

4 Pages

-

C632B Hot Tack Tester

3 Pages

-

C632M Hot tack Tester

3 Pages

-

Tensile Testing Device

3 Pages

-

Peel Force Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

"ELEMENDORF" test device

2 Pages

-

C680M Tearing Tester

2 Pages

-

C650H Headspace Gas Analyzer

2 Pages

-

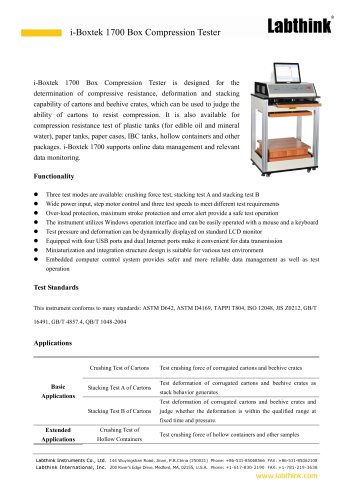

Box Compression Tester

2 Pages

-

Peel Force Tester

3 Pages

-

Pull Off Adhesion Tester

3 Pages

-

Torque Measuring Devices

3 Pages

-

Bottle Torque Tester

3 Pages

-

Packaging Burst Tester

3 Pages

-

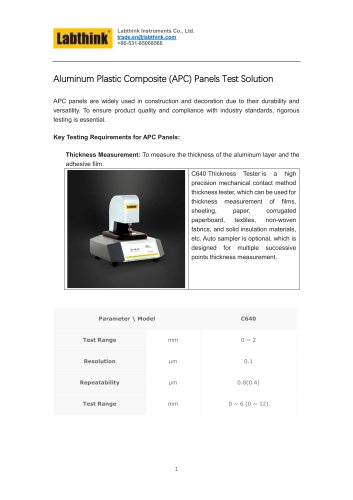

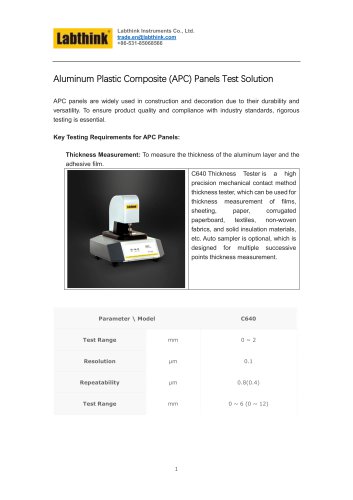

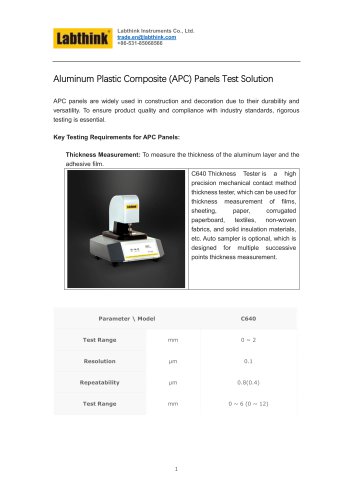

PARAM C640 Thickness Tester

4 Pages

-

Torque Strength Measuring

3 Pages

-

Bottle Leak Tester Machine

3 Pages

-

Oxygen Transmission Tester

4 Pages

-

C612M Digital Torque Tester

3 Pages

-

Bag COF Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Sandwich Bag COF Tester

2 Pages

-

Textile Thickness Gauge

4 Pages

-

C680M Tearing Tester

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Heat Shrink Tester

2 Pages

-

Tensile Testing Device

3 Pages

-

MAP Packaging Burst Tester

3 Pages

-

MAP Packaging Leak Tester

3 Pages

-

Lug Cap Torque Tester

3 Pages

-

Motorized Pull Test Machine

3 Pages

-

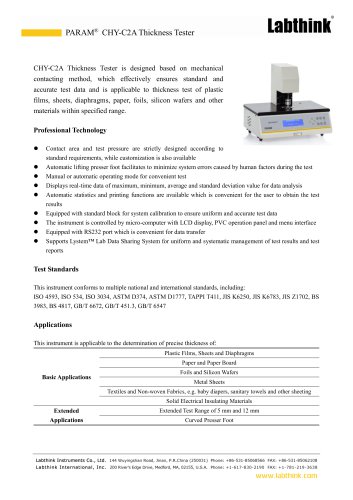

CHY-C2A Thickness Tester

2 Pages

-

Heat Seal Tester

3 Pages

-

Roll Tack Tester

1 Pages

-

Spot Thickness Measurement

4 Pages

-

Adhesive Tack Tester

2 Pages

-

Vacuum Bag Leak Tester

3 Pages

-

Micron Film Thickness Gauge

4 Pages

-

Spot thickness measurement

4 Pages

-

Automatic Tube Leak Tester

2 Pages

-

Burst Test Equipment

3 Pages

-

Elongation Tester

3 Pages

-

Box Compression Test Machine

2 Pages

-

Adhesion Tester for Sticker

2 Pages

-

Ink Rub Lab Equipment

2 Pages

-

Friction Testing Machine

3 Pages

-

Fabric Thickness Measurement

4 Pages

-

Snack Bag Leak Detector

3 Pages

-

Carton Stacking Test Machine

2 Pages

-

Sheet Metal Thickness Gauge

4 Pages

-

Residual oxygen level tester

2 Pages

-

Vacuum Tube Leak Tester

3 Pages

-

leak detector for packaging

3 Pages

-

bottle torque tester machine

3 Pages

-

micrometer per ASTM D374

4 Pages

-

rub tester for wine labels

2 Pages

-

LAB THICNESS TESTER

3 Pages

-

Peel tester for 180 Degree

5 Pages

-

Ball tack tester

5 Pages

-

table top thickness gauge

12 Pages

-

Tabletop sealing machine

14 Pages

-

Film Friction Tester

2 Pages

-

Head space Oxygen Analyser

2 Pages

-

90 degree peel test Device

3 Pages

-

C681M Flex Durability Tester

2 Pages

-

C650M Headspace Gas Analyzer

2 Pages

-

C650B Headspace Gas Analyzer

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

C620H Friction

3 Pages

-

C611M Box Compression Tester

2 Pages

-

C611B Box Compression Tester

2 Pages

-

C610M Auto Tensile Tester

3 Pages

-

C610H Auto Tensile Tester

3 Pages

-

Handheld Headspace Analyzer

2 Pages

-

Cap Torque Machine

5 Pages

-

Oxygen Permeation Analyser

3 Pages

-

Oxygen Permeation Apparatus

3 Pages

-

Papier Abrieb-Testmaschine

1 Pages

-

Bottle Cap Leak Tester

4 Pages

-

torque meter for PET Bottles

3 Pages

-

box compression device

5 Pages

-

BLJ-02 Disk Stripping Tester

2 Pages

-

RT-01 Rub Tester

2 Pages

-

MCJ-01A Rub Tester

2 Pages

-

Floor Slip Resistance Tester

5 Pages

-

Leak Tester

3 Pages

-

Consultative Testing Service

4 Pages

-

BOPP Tape Shear Tester

3 Pages

-

Bell Jar leak tester

2 Pages

-

COF testing of Polymer Films

2 Pages

-

labthink MFY-01 Leak Tester

3 Pages

-

Heat Sealing Property Tester

1 Pages

-

Tablet Leak Test Apparatus

5 Pages

-

Precise Tape Peeling Tester

5 Pages

-

BOPP Film Thickness Meter

2 Pages

-

Package Headspace Analyzer

5 Pages

-

electrical torque meter

5 Pages

-

tape peeling tester

5 Pages

-

tensile testing instrument

5 Pages

-

gas leakage detector LSSD-01

5 Pages

-

XLW (G6) Auto Tensile Tester

3 Pages

-

XLW (M) Auto Tensile Tester

3 Pages

-

XLW (B) Auto Tensile Tester

2 Pages

-

XLW Auto Tensile Tester

3 Pages

-

CHY-C2 Thickness Tester

2 Pages

-

CHY-CA Thickness Tester

2 Pages

-

XLW (PC) Auto Tensile Tester

3 Pages

-

Plastic Film Thickness Test

2 Pages

-

Tensile Strength Machine

5 Pages

-

fogging testing machine

5 Pages

-

heat sealing testing machine

5 Pages

-

shrinkage testing machine

5 Pages

-

torque testing machine

5 Pages

-

Medical Package leak Tester

5 Pages

-

Food Package leak Tester

5 Pages

-

ink rubbing test machine

5 Pages

-

rolling ball tack tester

5 Pages

-

Glebo flex tester

5 Pages

-

hot tack tester

5 Pages

-

tape peel force tester

5 Pages

-

Rolling Ball Tester

5 Pages

-

permeability apparatus

5 Pages

-

CHY-CB Thickness Tester

2 Pages

-

Heat Shrinkage Force Tester

5 Pages

-

XLW (EC) Auto Tensile Tester

3 Pages

-

gas leakage detector MFY-01

5 Pages

-

materials Flex tester

5 Pages

-

oxygen headspace analyzer

5 Pages

-

cap torque testing machine

5 Pages

-

Lasting Ahesion Tester

5 Pages

-

Peeling strength tester

5 Pages

-

Torque Measurement Equipment

2 Pages

-

Heat Sealing Test machine

1 Pages

-

FDI-01

5 Pages

-

Leakage Detector

5 Pages

-

Rolling Ball Adhesion Tester

1 Pages

-

film thickness gauge

5 Pages

-

rub testing machine

5 Pages

-

air leakage tester

5 Pages

-

vacuum leak detector

4 Pages

-

plastic film testing machine

3 Pages

-

carton compression test

5 Pages

-

plastic cap torque tester

5 Pages

-

manual torque tester

1 Pages

-

opening torque tester

2 Pages

-

Oxygen headspace Analyzer

2 Pages

-

Permeability Test System

2 Pages

-

DIN 75201

2 Pages

-

Tensile strength test bench

5 Pages

-

impact testing equipments

2 Pages

-

thickness gauge

5 Pages

-

vacuum leak testing machine

2 Pages

-

paper thickness measurement

5 Pages

-

FDT-02 Gelbo Flex Tester

5 Pages

-

Friction Coefficient Tester

5 Pages

-

Drop Ball Impact Tester

5 Pages

-

Dealers wanted

1 Pages

-

Abrasion Resistance Tester

2 Pages

-

HST-H3 Heat Sealing Machine

1 Pages

-

FPT-F1 Friction/ Peel Tester

2 Pages

-

FT-F1 Fogging Tester

2 Pages

-

Material Testing Equipment

2 Pages

-

Packaging Testing

2 Pages

-

Abrasion Test

2 Pages

-

Torque Meter

2 Pages

-

pendulum impact tester

2 Pages

-

Oxygen Transmission Analyzer

2 Pages

-

Friction Tester

2 Pages

-

Leak Detector

2 Pages

-

Analyzer for MAP

2 Pages

-

Adhesive Strength Tester

1 Pages

-

O2 & CO2 Analyzer

1 Pages

-

Gas Permeability Tester

2 Pages

-

Heat Thermal Shrink Tester

1 Pages

-

Paper Air Resistance Tester

1 Pages

-

Lasting Adhesive Tester

2 Pages

-

Cap Torque Tester

3 Pages

-

Lasting Adhesion Tester

2 Pages

-

Gradient Heat Seal Tester

4 Pages

-

Head space gas Analysis

4 Pages

-

Headspace Gas Analyser

3 Pages

-

Headspace Gas Analyzer

3 Pages

-

Material Tensile Tester

5 Pages

-

Ink Rub Tester

2 Pages

-

medical packaging tester

3 Pages

-

Hot Tack Tester (Data Sheet)

2 Pages

-

Heat Sealing tester

2 Pages

-

Evaporation Residue Tester

3 Pages

-

Blister Package testing

3 Pages

-

Gas Permeability Analyzer

3 Pages

-

Tensile Testing Machine

2 Pages

-

package integrity tester

2 Pages

-

Oxygen permeation Analyzer

2 Pages

-

Drop Impact Tester

2 Pages

-

Torque tester

2 Pages

-

Compression Testing Machine

2 Pages

-

Material Testing Machine

3 Pages

-

Shrink Film testing

2 Pages

-

fogging tester

2 Pages

-

Impact tester

2 Pages

-

Quality Concerns of Doypacks

2 Pages

-

Material Testing

2 Pages

-

laboratory heat sealer

2 Pages

-

Automated Heat Sealer

1 Pages

-

analog thickness gauge

1 Pages

-

Residual Gas Analyzer

1 Pages

-

digital torque gauge

1 Pages

-

packaging Industry

2 Pages

-

Metrology and Test Equipment

2 Pages

-

Tensile Tester

2 Pages

-

material moisture monitor

2 Pages

-

Gas Analyzer

2 Pages

-

Headspace Gas Analyzer

1 Pages

-

FRICTION/PEEL TESTER

1 Pages

-

HOLDING TACK TESTER

1 Pages

-

ROLLING BALL TESTER

1 Pages

-

BOX COMPRESSION TESTER

1 Pages

-

INK RUB TESTER

1 Pages

-

FOGGING TESTER

2 Pages

-

Film Shrinkage Tester

1 Pages

-

Film Pendulum Impact Tester

1 Pages

-

FALLING DART IMPACT TESTER

1 Pages

-

THICKNESS TESTER

1 Pages

-

TOQUE TESTER

1 Pages

-

Tearing Tester

1 Pages

-

Gas Permeability Tester

1 Pages

-

Oxygen Permeability Tester

2 Pages

Archived catalogs

-

Leak Tester

2 Pages