Website:

Labthink Instruments Co., Ltd.

Website:

Labthink Instruments Co., Ltd.

Group: Labthink

Catalog excerpts

Full Performance Solutions for Pharmaceutical Packaging and Medical Devices Labthink Instruments Company launched its PRAMA MED-01 Medical Packaging Tester. Equipped with 17 independent test modes and more than 100 grips, MED-01 Medical Packaging Tester can carry out test for over 1000 materials. Below are the detailed testing methods that MED-01 Medical Packaging Tester used to test some typical pharmaceutical packaging and medical devices: rubber closures, flexible packaging bags, syringes and ampoule. 1. Medical Rubber Closure prepare the specimen. Take 10 pcs of tested closures and parameter-preset closures respectively and place them onto half-filled infusion bottles. Seal the bottles with aluminum caps and keep them inside the hi-pressure steam sterilizer under temperature of 121℃± 2℃. After a period of 20min, reduce to room temperature and carry them out. Next, prepare puncture test apparatus as in accordance with diagram 1, then place the bottle at the designated position where the closure center set to be punctured, and set the puncture speed at 200± 50mm/min. Start to have specimens tested alternatively and record the force imposed having the bottle pierced. Test stops by the last prepared specimen.

Open the catalog to page 1

Diagram 1 Puncture test for medical rubber closure Note: 淬硬-quench hardened As stipulated, the maximal force to pierce the bottle should be less than 80N and averaged at 75N, and no closures should be pressed into the bottles. Procedures as demonstrated in diagram 2.

Open the catalog to page 2

Diagram 1 Puncture test for medical rubber closure 2. Medical flexible plastic packaging bag Widely used in pharmaceutical industry, medical flexible plastic packaging bags (referred to as bag or bags) have various applications such as blood bag and infusion bag depending on the fields. In order to ensure sound and standard application performance, scientific industry standard has been elaborated on the bags of various forms. Take blood bag as an example, specific contents on its structure and size, material, appearance, physical property, chemical property as well as biological property...

Open the catalog to page 3

Diagram 3 structure of disposable plastic blood bag 1-保护件-protective part, 2-包括堵塞装置可以没有的转移管-transfer line with/without blockage, 3-输血插口-blood transfusion interface, 4-孔眼-hole, 5-采血管-blood collection tube, 6-标签区-label position, 7-保护箱-protective case, 8-采血针-blood taking needle Test procedures: fill the blood bag with distilled water of PH value at5.5-5.6 to nominal capacity, then put it into a centrifugal cup. Impose 5000g centrifugal force for 30min at 4℃ and 12℃ respectively, followed by placing the bag between two flat panels and sticking the blue litmus paper. Gradually increase the...

Open the catalog to page 4

low in cost, its defects are also noticeable: inconvenience, poor acid/alkali resistance, environment pollutants. Early 1990s emerged a new pharmaceutical packaging, which functioned both as storage and injector, as well were made up of materials with sound compatibility and stability. Compared with traditional “bottle-syringe” model, the new design, convenient in usage and low potential environment pollution risk, maximally reduced cost from producing to using. That was refilled syringes, massively applied and manufactured. However, on the opposite side, in case the refilled syringes...

Open the catalog to page 5

Diagram 5 sketch of needle base-needle-cap 1-针座-needle base, 2-连接部-connection, 3-针管-needle, 4-护套-cap Connection force refers to the test of fastness between needle and base. The highlight of the test is through the determination of reasonable fastness coefficient to reduce hazard to life caused by separation of needle and base during injection. The test keeps the needle onto the driving mechanism connected with measuring instrument, and is carried out by pulling at speed of (100 ±5)mm/min with pulling force no less than 22N (pulling force between 22-69N while needle diameter 0.3-1.2mm)....

Open the catalog to page 6

Diagram 6 fastness test of needle and base Piston sliding resistance refers to the opening force at the very start of and sustaining force during the piston movement, and aims to the evaluation of piston movement resistance. Mostly, syringes are operated by delicate females, force excessive would on one hand cause injection impossible and on the other risk the life of patient as potion may be injected into body instantly as piston rod pushed heavily. In the test, refilled syringe as shown in the following diagram is clamped and its rod both pulled and pushed by driving mechanism. The real...

Open the catalog to page 7

Diagram 7 piston sliding resistance test Table 1 sliding resistance Nominal capacityml Opening forceFmax Sustaining forceFmax 4. Ampoule Ampoule, slim in neck and thick in body, is a type of tiny sealed glass bottle containing potion and oral liquid, etc, and normally used by break its neck with hands or assisted by grinding wheel and saw unit. According to statistics, glass related injury tops the injuries caused by medical appliances

Open the catalog to page 8

with a percentage of 54.4%, which partly because instructions are not fully followed and partly because the poor quality of Ampoules that either with poor fracture resistance or neck too hard to break. Therefore, fracture resistance is a vital test item to Ampoule. Diagram 8 fracture resistance test of Ampoule Firstly mount relative test accessories as shown in diagram 8. Place one piece specimen on to the supportive panel, keep Ampoule neck perpendicular to the center of upper test instrument. Set test rate, parameters and click start button to start the test automatically. Test data,...

Open the catalog to page 9

medical packaging performance tester, suitable to basic tests like tensile strength, tear, hot seal and peel resistance, and can be extended to tests of puncture test to artificial skin, permeability of syringe body, tear strength of oral liquid cap, rubber closure pullout resistance, opening resistance of combined caps, is the most powerful and advanced test instrument with most comprehensive functions in pharmaceuticals packaging industry.

Open the catalog to page 10All Labthink Instruments Co. catalogs and technical brochures

-

C630H Heat Seal Tester

3 Pages

-

C610M Auto Tensile Tester

3 Pages

-

Heat seal testing instrument

3 Pages

-

Paper Board Thickness Tester

4 Pages

-

Film Thickness Meter

4 Pages

-

C632B Hot Tack Tester

3 Pages

-

C632M Hot tack Tester

3 Pages

-

Tensile Testing Device

3 Pages

-

Peel Force Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

"ELEMENDORF" test device

2 Pages

-

C680M Tearing Tester

2 Pages

-

C650H Headspace Gas Analyzer

2 Pages

-

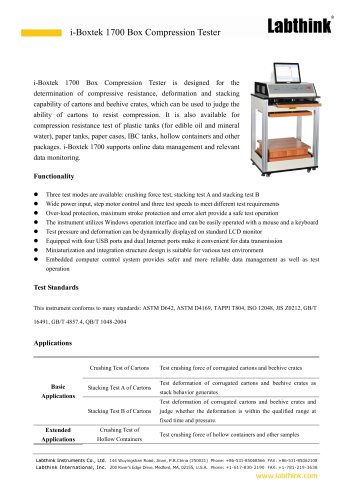

Box Compression Tester

2 Pages

-

Peel Force Tester

3 Pages

-

Pull Off Adhesion Tester

3 Pages

-

Torque Measuring Devices

3 Pages

-

Bottle Torque Tester

3 Pages

-

Packaging Burst Tester

3 Pages

-

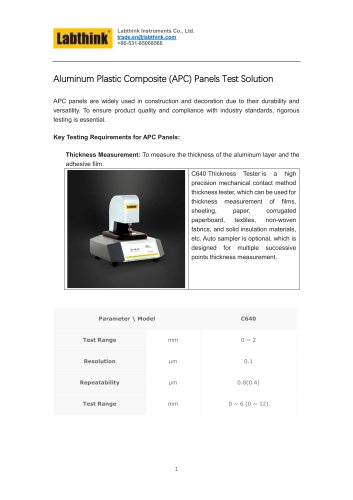

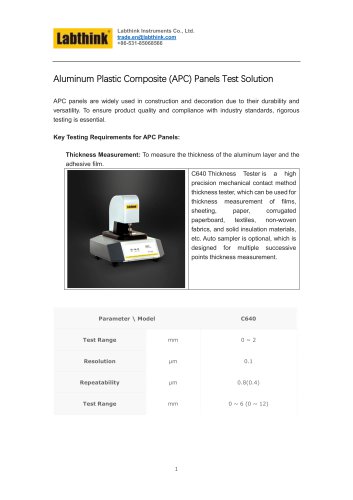

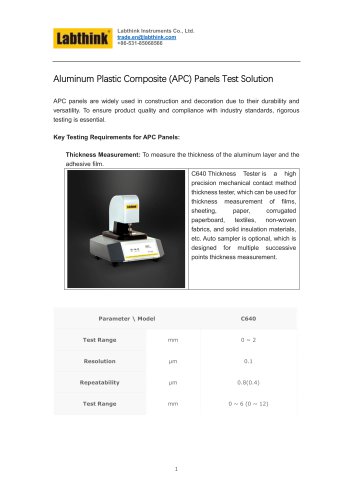

PARAM C640 Thickness Tester

4 Pages

-

Torque Strength Measuring

3 Pages

-

Bottle Leak Tester Machine

3 Pages

-

Oxygen Transmission Tester

4 Pages

-

C612M Digital Torque Tester

3 Pages

-

Bag COF Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Sandwich Bag COF Tester

2 Pages

-

Textile Thickness Gauge

4 Pages

-

C680M Tearing Tester

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Heat Shrink Tester

2 Pages

-

Tensile Testing Device

3 Pages

-

MAP Packaging Burst Tester

3 Pages

-

MAP Packaging Leak Tester

3 Pages

-

Lug Cap Torque Tester

3 Pages

-

Motorized Pull Test Machine

3 Pages

-

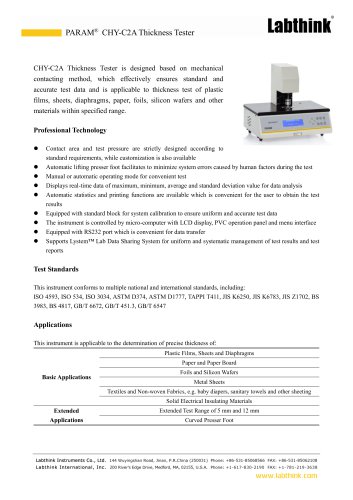

CHY-C2A Thickness Tester

2 Pages

-

Heat Seal Tester

3 Pages

-

Roll Tack Tester

1 Pages

-

Spot Thickness Measurement

4 Pages

-

Adhesive Tack Tester

2 Pages

-

Vacuum Bag Leak Tester

3 Pages

-

Micron Film Thickness Gauge

4 Pages

-

Spot thickness measurement

4 Pages

-

Automatic Tube Leak Tester

2 Pages

-

Burst Test Equipment

3 Pages

-

Elongation Tester

3 Pages

-

Box Compression Test Machine

2 Pages

-

Adhesion Tester for Sticker

2 Pages

-

Ink Rub Lab Equipment

2 Pages

-

Friction Testing Machine

3 Pages

-

Fabric Thickness Measurement

4 Pages

-

Snack Bag Leak Detector

3 Pages

-

Carton Stacking Test Machine

2 Pages

-

Sheet Metal Thickness Gauge

4 Pages

-

Residual oxygen level tester

2 Pages

-

Vacuum Tube Leak Tester

3 Pages

-

leak detector for packaging

3 Pages

-

bottle torque tester machine

3 Pages

-

micrometer per ASTM D374

4 Pages

-

rub tester for wine labels

2 Pages

-

LAB THICNESS TESTER

3 Pages

-

Peel tester for 180 Degree

5 Pages

-

Ball tack tester

5 Pages

-

table top thickness gauge

12 Pages

-

Tabletop sealing machine

14 Pages

-

Film Friction Tester

2 Pages

-

Head space Oxygen Analyser

2 Pages

-

90 degree peel test Device

3 Pages

-

C681M Flex Durability Tester

2 Pages

-

C650M Headspace Gas Analyzer

2 Pages

-

C650B Headspace Gas Analyzer

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

C620H Friction

3 Pages

-

C611M Box Compression Tester

2 Pages

-

C611B Box Compression Tester

2 Pages

-

C610M Auto Tensile Tester

3 Pages

-

C610H Auto Tensile Tester

3 Pages

-

Handheld Headspace Analyzer

2 Pages

-

Cap Torque Machine

5 Pages

-

Oxygen Permeation Analyser

3 Pages

-

Oxygen Permeation Apparatus

3 Pages

-

Papier Abrieb-Testmaschine

1 Pages

-

Bottle Cap Leak Tester

4 Pages

-

torque meter for PET Bottles

3 Pages

-

box compression device

5 Pages

-

BLJ-02 Disk Stripping Tester

2 Pages

-

RT-01 Rub Tester

2 Pages

-

MCJ-01A Rub Tester

2 Pages

-

Floor Slip Resistance Tester

5 Pages

-

Leak Tester

3 Pages

-

Consultative Testing Service

4 Pages

-

BOPP Tape Shear Tester

3 Pages

-

Bell Jar leak tester

2 Pages

-

COF testing of Polymer Films

2 Pages

-

labthink MFY-01 Leak Tester

3 Pages

-

Heat Sealing Property Tester

1 Pages

-

Tablet Leak Test Apparatus

5 Pages

-

Precise Tape Peeling Tester

5 Pages

-

BOPP Film Thickness Meter

2 Pages

-

Package Headspace Analyzer

5 Pages

-

electrical torque meter

5 Pages

-

tape peeling tester

5 Pages

-

tensile testing instrument

5 Pages

-

gas leakage detector LSSD-01

5 Pages

-

XLW (G6) Auto Tensile Tester

3 Pages

-

XLW (M) Auto Tensile Tester

3 Pages

-

XLW (B) Auto Tensile Tester

2 Pages

-

XLW Auto Tensile Tester

3 Pages

-

CHY-C2 Thickness Tester

2 Pages

-

CHY-CA Thickness Tester

2 Pages

-

XLW (PC) Auto Tensile Tester

3 Pages

-

Plastic Film Thickness Test

2 Pages

-

Tensile Strength Machine

5 Pages

-

fogging testing machine

5 Pages

-

heat sealing testing machine

5 Pages

-

shrinkage testing machine

5 Pages

-

torque testing machine

5 Pages

-

Medical Package leak Tester

5 Pages

-

Food Package leak Tester

5 Pages

-

ink rubbing test machine

5 Pages

-

rolling ball tack tester

5 Pages

-

Glebo flex tester

5 Pages

-

hot tack tester

5 Pages

-

tape peel force tester

5 Pages

-

Rolling Ball Tester

5 Pages

-

permeability apparatus

5 Pages

-

CHY-CB Thickness Tester

2 Pages

-

Heat Shrinkage Force Tester

5 Pages

-

XLW (EC) Auto Tensile Tester

3 Pages

-

gas leakage detector MFY-01

5 Pages

-

materials Flex tester

5 Pages

-

oxygen headspace analyzer

5 Pages

-

cap torque testing machine

5 Pages

-

Lasting Ahesion Tester

5 Pages

-

Peeling strength tester

5 Pages

-

Torque Measurement Equipment

2 Pages

-

Heat Sealing Test machine

1 Pages

-

FDI-01

5 Pages

-

Leakage Detector

5 Pages

-

Rolling Ball Adhesion Tester

1 Pages

-

film thickness gauge

5 Pages

-

rub testing machine

5 Pages

-

air leakage tester

5 Pages

-

vacuum leak detector

4 Pages

-

plastic film testing machine

3 Pages

-

carton compression test

5 Pages

-

plastic cap torque tester

5 Pages

-

manual torque tester

1 Pages

-

opening torque tester

2 Pages

-

Oxygen headspace Analyzer

2 Pages

-

Permeability Test System

2 Pages

-

DIN 75201

2 Pages

-

Tensile strength test bench

5 Pages

-

impact testing equipments

2 Pages

-

thickness gauge

5 Pages

-

vacuum leak testing machine

2 Pages

-

paper thickness measurement

5 Pages

-

FDT-02 Gelbo Flex Tester

5 Pages

-

Friction Coefficient Tester

5 Pages

-

Drop Ball Impact Tester

5 Pages

-

Dealers wanted

1 Pages

-

Abrasion Resistance Tester

2 Pages

-

HST-H3 Heat Sealing Machine

1 Pages

-

FPT-F1 Friction/ Peel Tester

2 Pages

-

FT-F1 Fogging Tester

2 Pages

-

Material Testing Equipment

2 Pages

-

Packaging Testing

2 Pages

-

Abrasion Test

2 Pages

-

Torque Meter

2 Pages

-

pendulum impact tester

2 Pages

-

Oxygen Transmission Analyzer

2 Pages

-

Friction Tester

2 Pages

-

Leak Detector

2 Pages

-

Analyzer for MAP

2 Pages

-

Adhesive Strength Tester

1 Pages

-

O2 & CO2 Analyzer

1 Pages

-

Gas Permeability Tester

2 Pages

-

Heat Thermal Shrink Tester

1 Pages

-

Paper Air Resistance Tester

1 Pages

-

Lasting Adhesive Tester

2 Pages

-

Cap Torque Tester

3 Pages

-

Lasting Adhesion Tester

2 Pages

-

Gradient Heat Seal Tester

4 Pages

-

Head space gas Analysis

4 Pages

-

Headspace Gas Analyser

3 Pages

-

Headspace Gas Analyzer

3 Pages

-

Material Tensile Tester

5 Pages

-

Ink Rub Tester

2 Pages

-

medical packaging tester

3 Pages

-

Hot Tack Tester (Data Sheet)

2 Pages

-

Heat Sealing tester

2 Pages

-

Evaporation Residue Tester

3 Pages

-

Blister Package testing

3 Pages

-

Gas Permeability Analyzer

3 Pages

-

Tensile Testing Machine

2 Pages

-

package integrity tester

2 Pages

-

Oxygen permeation Analyzer

2 Pages

-

Drop Impact Tester

2 Pages

-

Torque tester

2 Pages

-

Compression Testing Machine

2 Pages

-

Material Testing Machine

3 Pages

-

Shrink Film testing

2 Pages

-

fogging tester

2 Pages

-

Impact tester

2 Pages

-

Quality Concerns of Doypacks

2 Pages

-

Material Testing

2 Pages

-

laboratory heat sealer

2 Pages

-

Automated Heat Sealer

1 Pages

-

analog thickness gauge

1 Pages

-

Residual Gas Analyzer

1 Pages

-

digital torque gauge

1 Pages

-

packaging Industry

2 Pages

-

Metrology and Test Equipment

2 Pages

-

Tensile Tester

2 Pages

-

material moisture monitor

2 Pages

-

Gas Analyzer

2 Pages

-

Headspace Gas Analyzer

1 Pages

-

FRICTION/PEEL TESTER

1 Pages

-

HOLDING TACK TESTER

1 Pages

-

ROLLING BALL TESTER

1 Pages

-

BOX COMPRESSION TESTER

1 Pages

-

INK RUB TESTER

1 Pages

-

FOGGING TESTER

2 Pages

-

Film Shrinkage Tester

1 Pages

-

Film Pendulum Impact Tester

1 Pages

-

FALLING DART IMPACT TESTER

1 Pages

-

THICKNESS TESTER

1 Pages

-

TOQUE TESTER

1 Pages

-

Tearing Tester

1 Pages

-

Gas Permeability Tester

1 Pages

-

Oxygen Permeability Tester

2 Pages

Archived catalogs

-

Leak Tester

2 Pages