Website:

Labthink Instruments Co., Ltd.

Website:

Labthink Instruments Co., Ltd.

Group: Labthink

Catalog excerpts

C670M Falling Dart Impact Tester C670M Falling Dart Impact Tester is suitable for measuring the impact mass and energy of plastic film or sheet when 50% of the sample is damaged under the impact of free falling dart at a given height. Menu interface, color touch screen operation, convenient and fast to set Two test modes A and B are provided, and the test status is automatically The falling dart adopts the principle of electromagnetic hanging, which can release automatically, effectively avoiding the system error caused by human factors. Pneumatic sample clamping, manual and pedal dual start mode, built-in observation lamp unique design; convenient, fast and accurate operation. Professional computer software supports the functions of multi unit display of test results, graphic display of test process, output and print function, showing the results clearly and intuitively. Micro printer and standard RS232 interface make the tester convenient for the external connection and data transmission between the system and the computer. Testing Principle At the beginning of the test, select the test method as the first procedure, estimate an initial mass and △m value, and conduct the test. If the first sample is damaged, the weight △m shall be used to reduce the falling mass; if the first sample is not broken, the weight △m shall be used to increase the falling mass for test in turn. In short, the use of weights to reduce or increase the falling mass depends on whether the previous sample is damaged. After 20 samples are tested, the total number of damaged samples is calculated. If n is equal to 10, the test is completed; if n is less than 10, continue the test after supplementing samples until n is equal to 10; if n is greater than 10, continue testing after supplementing samples until the total number of undamaged samples is equal to 10. Finally, the system automatically calculates the impact results. Reference Standard Note 1 ISO 7765-1-1988, ASTM D1709, GB/T 9639.1-2008, JIS K7124-1

Open the catalog to page 1

Basic Applications Film & Sheet It is suitable for testing the impact resistance of plastic film, sheet and composite film with thickness less than 1 mm. Such as PE film, wrapping film, PET sheet, food packaging bags of various structures, heavy packaging bags, etc Aluminum Foil, Aluminum Plastic Composite Film It is suitable for testing the impact resistance of aluminum foil and aluminum plastic composite film Paper and Paperboard Test It is suitable for testing the impact resistance of paper and paperboard Drop Ball Impact Test It is suitable for the drop ball impact test of the sample....

Open the catalog to page 2

Standard Configuration A method configuration, touch screen, micro printer Method B configuration, professional software and communication cable The air source interface of the machine is Φ 8 mm polyurethane pipe; the air source is provided by the user Notes1: The product functions, reference standards and configuration information are subject to the specific marks in the "technical indicators". Note 2: the parameters in the table are measured by professional operators in Labthink laboratory according to the requirements and conditions of relevant laboratory environmental standards....

Open the catalog to page 3All Labthink Instruments Co. catalogs and technical brochures

-

C630H Heat Seal Tester

3 Pages

-

C610M Auto Tensile Tester

3 Pages

-

Heat seal testing instrument

3 Pages

-

Paper Board Thickness Tester

4 Pages

-

Film Thickness Meter

4 Pages

-

C632B Hot Tack Tester

3 Pages

-

C632M Hot tack Tester

3 Pages

-

Tensile Testing Device

3 Pages

-

Peel Force Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

"ELEMENDORF" test device

2 Pages

-

C680M Tearing Tester

2 Pages

-

C650H Headspace Gas Analyzer

2 Pages

-

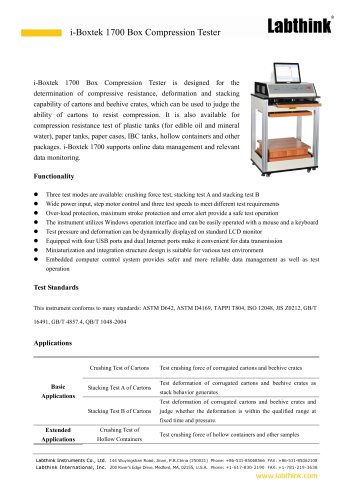

Box Compression Tester

2 Pages

-

Peel Force Tester

3 Pages

-

Pull Off Adhesion Tester

3 Pages

-

Torque Measuring Devices

3 Pages

-

Bottle Torque Tester

3 Pages

-

Packaging Burst Tester

3 Pages

-

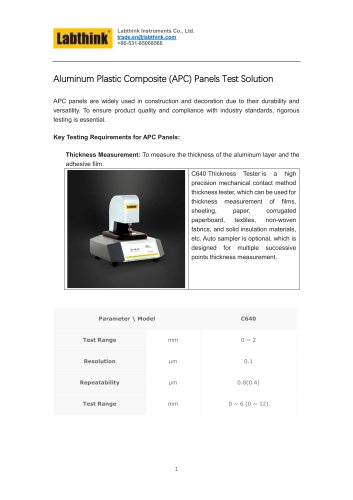

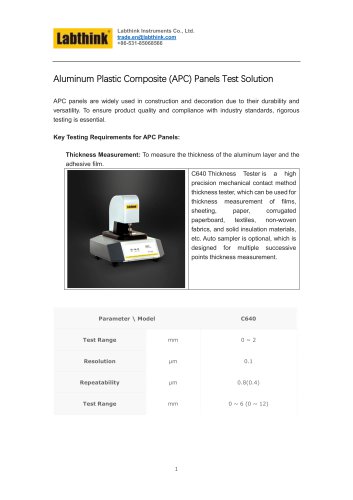

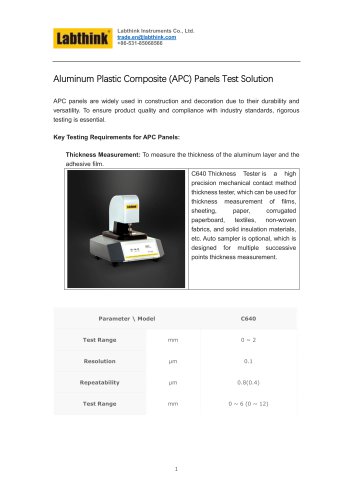

PARAM C640 Thickness Tester

4 Pages

-

Torque Strength Measuring

3 Pages

-

Bottle Leak Tester Machine

3 Pages

-

Oxygen Transmission Tester

4 Pages

-

C612M Digital Torque Tester

3 Pages

-

Bag COF Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Sandwich Bag COF Tester

2 Pages

-

Textile Thickness Gauge

4 Pages

-

C680M Tearing Tester

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Heat Shrink Tester

2 Pages

-

Tensile Testing Device

3 Pages

-

MAP Packaging Burst Tester

3 Pages

-

MAP Packaging Leak Tester

3 Pages

-

Lug Cap Torque Tester

3 Pages

-

Motorized Pull Test Machine

3 Pages

-

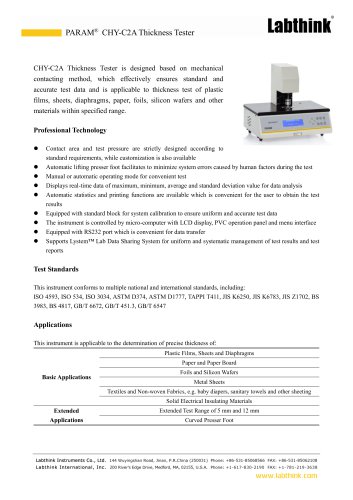

CHY-C2A Thickness Tester

2 Pages

-

Heat Seal Tester

3 Pages

-

Roll Tack Tester

1 Pages

-

Spot Thickness Measurement

4 Pages

-

Adhesive Tack Tester

2 Pages

-

Vacuum Bag Leak Tester

3 Pages

-

Micron Film Thickness Gauge

4 Pages

-

Spot thickness measurement

4 Pages

-

Automatic Tube Leak Tester

2 Pages

-

Burst Test Equipment

3 Pages

-

Elongation Tester

3 Pages

-

Box Compression Test Machine

2 Pages

-

Adhesion Tester for Sticker

2 Pages

-

Ink Rub Lab Equipment

2 Pages

-

Friction Testing Machine

3 Pages

-

Fabric Thickness Measurement

4 Pages

-

Snack Bag Leak Detector

3 Pages

-

Carton Stacking Test Machine

2 Pages

-

Sheet Metal Thickness Gauge

4 Pages

-

Residual oxygen level tester

2 Pages

-

Vacuum Tube Leak Tester

3 Pages

-

leak detector for packaging

3 Pages

-

bottle torque tester machine

3 Pages

-

micrometer per ASTM D374

4 Pages

-

rub tester for wine labels

2 Pages

-

LAB THICNESS TESTER

3 Pages

-

Peel tester for 180 Degree

5 Pages

-

Ball tack tester

5 Pages

-

table top thickness gauge

12 Pages

-

Tabletop sealing machine

14 Pages

-

Film Friction Tester

2 Pages

-

Head space Oxygen Analyser

2 Pages

-

90 degree peel test Device

3 Pages

-

C681M Flex Durability Tester

2 Pages

-

C650M Headspace Gas Analyzer

2 Pages

-

C650B Headspace Gas Analyzer

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

C620H Friction

3 Pages

-

C611M Box Compression Tester

2 Pages

-

C611B Box Compression Tester

2 Pages

-

C610M Auto Tensile Tester

3 Pages

-

C610H Auto Tensile Tester

3 Pages

-

Handheld Headspace Analyzer

2 Pages

-

Cap Torque Machine

5 Pages

-

Oxygen Permeation Analyser

3 Pages

-

Oxygen Permeation Apparatus

3 Pages

-

Papier Abrieb-Testmaschine

1 Pages

-

Bottle Cap Leak Tester

4 Pages

-

torque meter for PET Bottles

3 Pages

-

box compression device

5 Pages

-

BLJ-02 Disk Stripping Tester

2 Pages

-

RT-01 Rub Tester

2 Pages

-

MCJ-01A Rub Tester

2 Pages

-

Floor Slip Resistance Tester

5 Pages

-

Leak Tester

3 Pages

-

Consultative Testing Service

4 Pages

-

BOPP Tape Shear Tester

3 Pages

-

Bell Jar leak tester

2 Pages

-

COF testing of Polymer Films

2 Pages

-

labthink MFY-01 Leak Tester

3 Pages

-

Heat Sealing Property Tester

1 Pages

-

Tablet Leak Test Apparatus

5 Pages

-

Precise Tape Peeling Tester

5 Pages

-

BOPP Film Thickness Meter

2 Pages

-

Package Headspace Analyzer

5 Pages

-

electrical torque meter

5 Pages

-

tape peeling tester

5 Pages

-

tensile testing instrument

5 Pages

-

gas leakage detector LSSD-01

5 Pages

-

XLW (G6) Auto Tensile Tester

3 Pages

-

XLW (M) Auto Tensile Tester

3 Pages

-

XLW (B) Auto Tensile Tester

2 Pages

-

XLW Auto Tensile Tester

3 Pages

-

CHY-C2 Thickness Tester

2 Pages

-

CHY-CA Thickness Tester

2 Pages

-

XLW (PC) Auto Tensile Tester

3 Pages

-

Plastic Film Thickness Test

2 Pages

-

Tensile Strength Machine

5 Pages

-

fogging testing machine

5 Pages

-

heat sealing testing machine

5 Pages

-

shrinkage testing machine

5 Pages

-

torque testing machine

5 Pages

-

Medical Package leak Tester

5 Pages

-

Food Package leak Tester

5 Pages

-

ink rubbing test machine

5 Pages

-

rolling ball tack tester

5 Pages

-

Glebo flex tester

5 Pages

-

hot tack tester

5 Pages

-

tape peel force tester

5 Pages

-

Rolling Ball Tester

5 Pages

-

permeability apparatus

5 Pages

-

CHY-CB Thickness Tester

2 Pages

-

Heat Shrinkage Force Tester

5 Pages

-

XLW (EC) Auto Tensile Tester

3 Pages

-

gas leakage detector MFY-01

5 Pages

-

materials Flex tester

5 Pages

-

oxygen headspace analyzer

5 Pages

-

cap torque testing machine

5 Pages

-

Lasting Ahesion Tester

5 Pages

-

Peeling strength tester

5 Pages

-

Torque Measurement Equipment

2 Pages

-

Heat Sealing Test machine

1 Pages

-

FDI-01

5 Pages

-

Leakage Detector

5 Pages

-

Rolling Ball Adhesion Tester

1 Pages

-

film thickness gauge

5 Pages

-

rub testing machine

5 Pages

-

air leakage tester

5 Pages

-

vacuum leak detector

4 Pages

-

plastic film testing machine

3 Pages

-

carton compression test

5 Pages

-

plastic cap torque tester

5 Pages

-

manual torque tester

1 Pages

-

opening torque tester

2 Pages

-

Oxygen headspace Analyzer

2 Pages

-

Permeability Test System

2 Pages

-

DIN 75201

2 Pages

-

Tensile strength test bench

5 Pages

-

impact testing equipments

2 Pages

-

thickness gauge

5 Pages

-

vacuum leak testing machine

2 Pages

-

paper thickness measurement

5 Pages

-

FDT-02 Gelbo Flex Tester

5 Pages

-

Friction Coefficient Tester

5 Pages

-

Drop Ball Impact Tester

5 Pages

-

Dealers wanted

1 Pages

-

Abrasion Resistance Tester

2 Pages

-

HST-H3 Heat Sealing Machine

1 Pages

-

FPT-F1 Friction/ Peel Tester

2 Pages

-

FT-F1 Fogging Tester

2 Pages

-

Material Testing Equipment

2 Pages

-

Packaging Testing

2 Pages

-

Abrasion Test

2 Pages

-

Torque Meter

2 Pages

-

pendulum impact tester

2 Pages

-

Oxygen Transmission Analyzer

2 Pages

-

Friction Tester

2 Pages

-

Leak Detector

2 Pages

-

Analyzer for MAP

2 Pages

-

Adhesive Strength Tester

1 Pages

-

O2 & CO2 Analyzer

1 Pages

-

Gas Permeability Tester

2 Pages

-

Heat Thermal Shrink Tester

1 Pages

-

Paper Air Resistance Tester

1 Pages

-

Lasting Adhesive Tester

2 Pages

-

Cap Torque Tester

3 Pages

-

Lasting Adhesion Tester

2 Pages

-

Gradient Heat Seal Tester

4 Pages

-

Head space gas Analysis

4 Pages

-

Headspace Gas Analyser

3 Pages

-

Headspace Gas Analyzer

3 Pages

-

Material Tensile Tester

5 Pages

-

Ink Rub Tester

2 Pages

-

medical packaging tester

3 Pages

-

Hot Tack Tester (Data Sheet)

2 Pages

-

Heat Sealing tester

2 Pages

-

Evaporation Residue Tester

3 Pages

-

Blister Package testing

3 Pages

-

Gas Permeability Analyzer

3 Pages

-

Tensile Testing Machine

2 Pages

-

package integrity tester

2 Pages

-

Oxygen permeation Analyzer

2 Pages

-

Drop Impact Tester

2 Pages

-

Torque tester

2 Pages

-

Compression Testing Machine

2 Pages

-

Material Testing Machine

3 Pages

-

Shrink Film testing

2 Pages

-

fogging tester

2 Pages

-

Impact tester

2 Pages

-

Quality Concerns of Doypacks

2 Pages

-

Material Testing

2 Pages

-

laboratory heat sealer

2 Pages

-

Automated Heat Sealer

1 Pages

-

analog thickness gauge

1 Pages

-

Residual Gas Analyzer

1 Pages

-

digital torque gauge

1 Pages

-

packaging Industry

2 Pages

-

Metrology and Test Equipment

2 Pages

-

Tensile Tester

2 Pages

-

material moisture monitor

2 Pages

-

Gas Analyzer

2 Pages

-

Headspace Gas Analyzer

1 Pages

-

FRICTION/PEEL TESTER

1 Pages

-

HOLDING TACK TESTER

1 Pages

-

ROLLING BALL TESTER

1 Pages

-

BOX COMPRESSION TESTER

1 Pages

-

INK RUB TESTER

1 Pages

-

FOGGING TESTER

2 Pages

-

Film Shrinkage Tester

1 Pages

-

Film Pendulum Impact Tester

1 Pages

-

FALLING DART IMPACT TESTER

1 Pages

-

THICKNESS TESTER

1 Pages

-

TOQUE TESTER

1 Pages

-

Tearing Tester

1 Pages

-

Gas Permeability Tester

1 Pages

-

Oxygen Permeability Tester

2 Pages

Archived catalogs

-

Leak Tester

2 Pages