Website:

Labthink Instruments Co., Ltd.

Website:

Labthink Instruments Co., Ltd.

Group: Labthink

The Analysis on Infusion Bag Testing Requirements and Introduction to Relevant Testing Methods

3Pages

Catalog excerpts

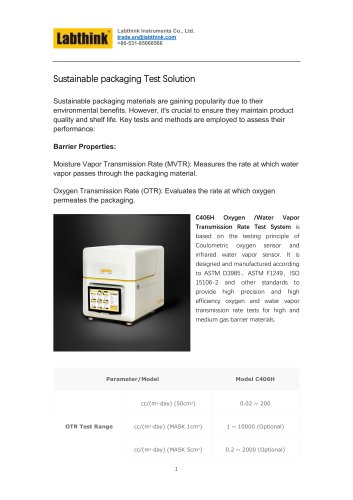

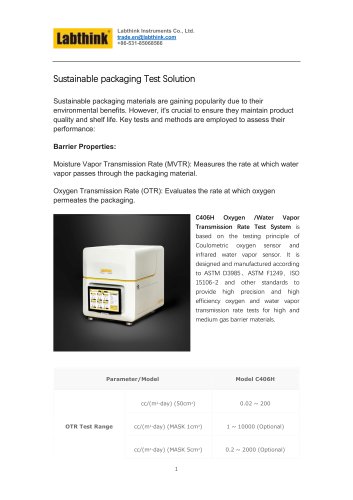

The Analysis on Infusion Bag Testing Requirements and Introduction to Relevant Testing Methods Abstract: Infusion bag (or IV bag) is the future trend for the packaging of injection liquid. This article analyses the testing requirements for infusion bags, and introduces the testing methods for specific indexes based on the testing standards for pharmaceutical packaging material. Key Words: infusion bag, oxygen transmission rate (OTR), nitrogen transmission rate, suspension force, piercing force Compared with traditional glass packaging, infusion bag is more environmental-friendly, cost-saving, safe, healthy and convenient. In USA and many European countries, plastic infusion package/container has taken up a great market share. Though fierce competition exists between infusion bag and plastic infusion bottle, the trend of flexible plastic packaging for injection liquid is irresistible. Differing from the traditional glass infusion bottle testing, more specific and appropriate performance testing for infusion bags should be applied so as to guarantee the safety of injection liquid. 1. The Analysis on the Testing Requirements for Infusion Bag Infusion bag is inferior to the glass bottle in the barrier property, sealing property and transparency; among which, barrier property is greatly influenced by material change. Oxygen is the main cause for deterioration of injection liquid. In order to lower the oxygen content inside the infusion bag and postpone/stop the oxidization of the injection liquid, anti-oxidants, metal chelate agents or inert gases are adopted. As to inert gases for this purpose, the most commonly applied inert gas is nitrogen. Water vapor would transmit into the bag and result in concentration change of the injection liquid, whose medicinal safety would be endangered. Therefore, barrier property testing is very important for infusion bag. Besides, the mechanical indexes of film materials and glass materials are fundamentally different. The mechanical testing for infusion bag is, therefore, very important. Meanwhile, the combinational closure used in the infusion bag should also be tested so as to meet the standards and actual application. 2. Barrier Property Testing for Infusion Bag The testing requirements for water vapor transmission rate (WVTR), oxygen transmission rate (OTR) and nitrogen transmission rate are stated in YBB00102005, 3-layer Co-extrusion Films and Bags Used for Infusion, and YBB00112005, 5-layer Co-extrusion Film (I) and Bags Used for Infusion. At present, the technology for whole infusion bag barrier property testing has become mature. Since there is no support from the national standards, the above-stated YBB standards don’t mention barrier property testing. Actually, owing to the evenness of the material, sealing property of the mouth and other factors, the actual gas transmission rate of the whole infusion bag is higher than the calculated value of the film. Thus, gas transmission rate testing of the whole infusion bag is of great need. Oxygen transmission rate (OTR) testing is mainly used for oxygen transmission rate measurement of infusion bag film materials, infusion bags or the whole infusion bottles. Equal pressure method and differential pressure method, the two methods for oxygen transmission rate testing can both test the oxygen transmission rate of films and of the whole infusion bags and bottles. Those two methods have their respective advantages: differential pressure method has no requirements for testing gas, and can be used to test the transmission rate of any gas. Thus, this method can be used to test nitrogen transmission rate without further costs. However, this method is still at the www.labthinkinternational.com.cn

Open the catalog to page 1

initial stage in package testing. On the other hand, equal pressure method has become mature both for film testing and package testing. Yet, there exist limitations for testing gas. Water vapor transmission rate (WVTR) testing is used for water vapor transmission rate measurement of infusion bag film materials, infusion bags or the whole infusion bottles. At present, weighing method and sensor method (including moisture sensor method, IR sensor method and electrolytic sensor method) can both be used to test water vapor transmission rate for films as well as for whole infusion bags and...

Open the catalog to page 2

4.3 Pull Open Force Testing The open easiness of the pull open cap ring would directly influence the operational convenience of the infusion bag and the safety of the injection liquid. This force should be within a specific force range so as to avoid open difficulty, low tensile force and the corresponding leakage caused by decreased sealing performance of the infusion bag. The pull open force can be tested in the following way: sterilize the specimen with wet heating treatment. Then, fix the specimen onto the fixture of the auto tensile tester, and the pull open ring onto the other...

Open the catalog to page 3All Labthink Instruments Co. catalogs and technical brochures

-

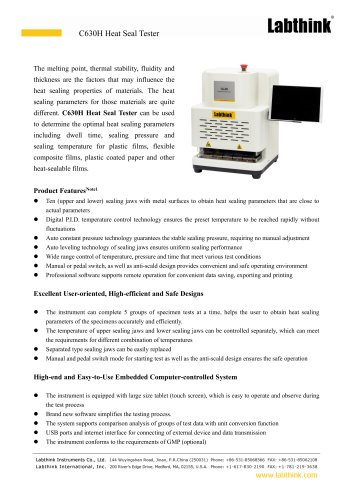

C630H Heat Seal Tester

3 Pages

-

C610M Auto Tensile Tester

3 Pages

-

Heat seal testing instrument

3 Pages

-

Paper Board Thickness Tester

4 Pages

-

Film Thickness Meter

4 Pages

-

C632B Hot Tack Tester

3 Pages

-

C632M Hot tack Tester

3 Pages

-

Tensile Testing Device

3 Pages

-

Peel Force Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

"ELEMENDORF" test device

2 Pages

-

C680M Tearing Tester

2 Pages

-

C650H Headspace Gas Analyzer

2 Pages

-

Box Compression Tester

2 Pages

-

Peel Force Tester

3 Pages

-

Pull Off Adhesion Tester

3 Pages

-

Torque Measuring Devices

3 Pages

-

Bottle Torque Tester

3 Pages

-

Packaging Burst Tester

3 Pages

-

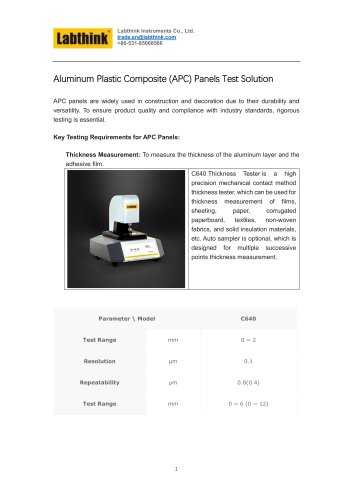

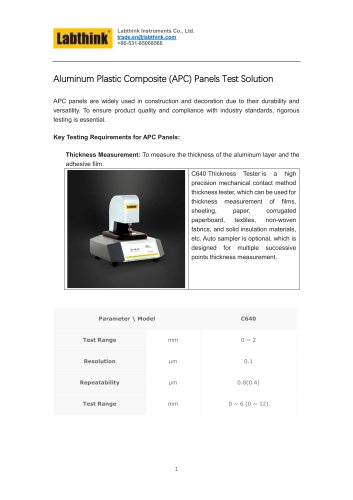

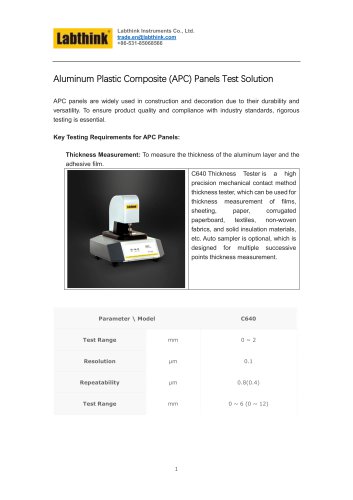

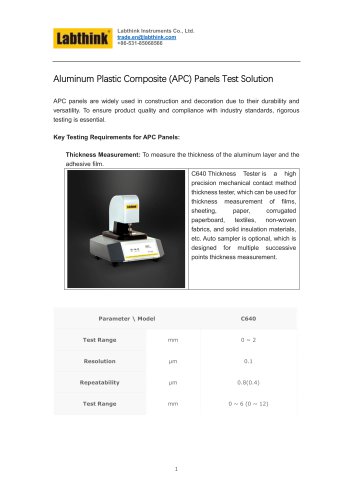

PARAM C640 Thickness Tester

4 Pages

-

Torque Strength Measuring

3 Pages

-

Bottle Leak Tester Machine

3 Pages

-

Oxygen Transmission Tester

4 Pages

-

C612M Digital Torque Tester

3 Pages

-

Bag COF Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Sandwich Bag COF Tester

2 Pages

-

Textile Thickness Gauge

4 Pages

-

C680M Tearing Tester

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

Labthink Headspace Analyzer

2 Pages

-

Heat Shrink Tester

2 Pages

-

Tensile Testing Device

3 Pages

-

MAP Packaging Burst Tester

3 Pages

-

MAP Packaging Leak Tester

3 Pages

-

Lug Cap Torque Tester

3 Pages

-

Motorized Pull Test Machine

3 Pages

-

CHY-C2A Thickness Tester

2 Pages

-

Heat Seal Tester

3 Pages

-

Roll Tack Tester

1 Pages

-

Spot Thickness Measurement

4 Pages

-

Adhesive Tack Tester

2 Pages

-

Vacuum Bag Leak Tester

3 Pages

-

Micron Film Thickness Gauge

4 Pages

-

Spot thickness measurement

4 Pages

-

Automatic Tube Leak Tester

2 Pages

-

Burst Test Equipment

3 Pages

-

Elongation Tester

3 Pages

-

Box Compression Test Machine

2 Pages

-

Adhesion Tester for Sticker

2 Pages

-

Ink Rub Lab Equipment

2 Pages

-

Friction Testing Machine

3 Pages

-

Fabric Thickness Measurement

4 Pages

-

Snack Bag Leak Detector

3 Pages

-

Carton Stacking Test Machine

2 Pages

-

Sheet Metal Thickness Gauge

4 Pages

-

Residual oxygen level tester

2 Pages

-

Vacuum Tube Leak Tester

3 Pages

-

leak detector for packaging

3 Pages

-

bottle torque tester machine

3 Pages

-

micrometer per ASTM D374

4 Pages

-

rub tester for wine labels

2 Pages

-

LAB THICNESS TESTER

3 Pages

-

Peel tester for 180 Degree

5 Pages

-

Ball tack tester

5 Pages

-

table top thickness gauge

12 Pages

-

Tabletop sealing machine

14 Pages

-

Film Friction Tester

2 Pages

-

Head space Oxygen Analyser

2 Pages

-

90 degree peel test Device

3 Pages

-

C681M Flex Durability Tester

2 Pages

-

C650M Headspace Gas Analyzer

2 Pages

-

C650B Headspace Gas Analyzer

2 Pages

-

C632B Hot Tack Tester

3 Pages

-

C630H Heat Seal Tester

3 Pages

-

C620H Friction

3 Pages

-

C611M Box Compression Tester

2 Pages

-

C611B Box Compression Tester

2 Pages

-

C610M Auto Tensile Tester

3 Pages

-

C610H Auto Tensile Tester

3 Pages

-

Handheld Headspace Analyzer

2 Pages

-

Cap Torque Machine

5 Pages

-

Oxygen Permeation Analyser

3 Pages

-

Oxygen Permeation Apparatus

3 Pages

-

Papier Abrieb-Testmaschine

1 Pages

-

Bottle Cap Leak Tester

4 Pages

-

torque meter for PET Bottles

3 Pages

-

box compression device

5 Pages

-

BLJ-02 Disk Stripping Tester

2 Pages

-

RT-01 Rub Tester

2 Pages

-

MCJ-01A Rub Tester

2 Pages

-

Floor Slip Resistance Tester

5 Pages

-

Leak Tester

3 Pages

-

Consultative Testing Service

4 Pages

-

BOPP Tape Shear Tester

3 Pages

-

Bell Jar leak tester

2 Pages

-

COF testing of Polymer Films

2 Pages

-

labthink MFY-01 Leak Tester

3 Pages

-

Heat Sealing Property Tester

1 Pages

-

Tablet Leak Test Apparatus

5 Pages

-

Precise Tape Peeling Tester

5 Pages

-

BOPP Film Thickness Meter

2 Pages

-

Package Headspace Analyzer

5 Pages

-

electrical torque meter

5 Pages

-

tape peeling tester

5 Pages

-

tensile testing instrument

5 Pages

-

gas leakage detector LSSD-01

5 Pages

-

XLW (G6) Auto Tensile Tester

3 Pages

-

XLW (M) Auto Tensile Tester

3 Pages

-

XLW (B) Auto Tensile Tester

2 Pages

-

XLW Auto Tensile Tester

3 Pages

-

CHY-C2 Thickness Tester

2 Pages

-

CHY-CA Thickness Tester

2 Pages

-

XLW (PC) Auto Tensile Tester

3 Pages

-

Plastic Film Thickness Test

2 Pages

-

Tensile Strength Machine

5 Pages

-

fogging testing machine

5 Pages

-

heat sealing testing machine

5 Pages

-

shrinkage testing machine

5 Pages

-

torque testing machine

5 Pages

-

Medical Package leak Tester

5 Pages

-

Food Package leak Tester

5 Pages

-

ink rubbing test machine

5 Pages

-

rolling ball tack tester

5 Pages

-

Glebo flex tester

5 Pages

-

hot tack tester

5 Pages

-

tape peel force tester

5 Pages

-

Rolling Ball Tester

5 Pages

-

permeability apparatus

5 Pages

-

CHY-CB Thickness Tester

2 Pages

-

Heat Shrinkage Force Tester

5 Pages

-

XLW (EC) Auto Tensile Tester

3 Pages

-

gas leakage detector MFY-01

5 Pages

-

materials Flex tester

5 Pages

-

oxygen headspace analyzer

5 Pages

-

cap torque testing machine

5 Pages

-

Lasting Ahesion Tester

5 Pages

-

Peeling strength tester

5 Pages

-

Torque Measurement Equipment

2 Pages

-

Heat Sealing Test machine

1 Pages

-

FDI-01

5 Pages

-

Leakage Detector

5 Pages

-

Rolling Ball Adhesion Tester

1 Pages

-

film thickness gauge

5 Pages

-

rub testing machine

5 Pages

-

air leakage tester

5 Pages

-

vacuum leak detector

4 Pages

-

plastic film testing machine

3 Pages

-

carton compression test

5 Pages

-

plastic cap torque tester

5 Pages

-

manual torque tester

1 Pages

-

opening torque tester

2 Pages

-

Oxygen headspace Analyzer

2 Pages

-

Permeability Test System

2 Pages

-

DIN 75201

2 Pages

-

Tensile strength test bench

5 Pages

-

impact testing equipments

2 Pages

-

thickness gauge

5 Pages

-

vacuum leak testing machine

2 Pages

-

paper thickness measurement

5 Pages

-

FDT-02 Gelbo Flex Tester

5 Pages

-

Friction Coefficient Tester

5 Pages

-

Drop Ball Impact Tester

5 Pages

-

Dealers wanted

1 Pages

-

Abrasion Resistance Tester

2 Pages

-

HST-H3 Heat Sealing Machine

1 Pages

-

FPT-F1 Friction/ Peel Tester

2 Pages

-

FT-F1 Fogging Tester

2 Pages

-

Material Testing Equipment

2 Pages

-

Packaging Testing

2 Pages

-

Abrasion Test

2 Pages

-

Torque Meter

2 Pages

-

pendulum impact tester

2 Pages

-

Oxygen Transmission Analyzer

2 Pages

-

Friction Tester

2 Pages

-

Leak Detector

2 Pages

-

Analyzer for MAP

2 Pages

-

Adhesive Strength Tester

1 Pages

-

O2 & CO2 Analyzer

1 Pages

-

Gas Permeability Tester

2 Pages

-

Heat Thermal Shrink Tester

1 Pages

-

Paper Air Resistance Tester

1 Pages

-

Lasting Adhesive Tester

2 Pages

-

Cap Torque Tester

3 Pages

-

Lasting Adhesion Tester

2 Pages

-

Gradient Heat Seal Tester

4 Pages

-

Head space gas Analysis

4 Pages

-

Headspace Gas Analyser

3 Pages

-

Headspace Gas Analyzer

3 Pages

-

Material Tensile Tester

5 Pages

-

Ink Rub Tester

2 Pages

-

medical packaging tester

3 Pages

-

Hot Tack Tester (Data Sheet)

2 Pages

-

Heat Sealing tester

2 Pages

-

Evaporation Residue Tester

3 Pages

-

Blister Package testing

3 Pages

-

Gas Permeability Analyzer

3 Pages

-

Tensile Testing Machine

2 Pages

-

package integrity tester

2 Pages

-

Oxygen permeation Analyzer

2 Pages

-

Drop Impact Tester

2 Pages

-

Torque tester

2 Pages

-

Compression Testing Machine

2 Pages

-

Material Testing Machine

3 Pages

-

Shrink Film testing

2 Pages

-

fogging tester

2 Pages

-

Impact tester

2 Pages

-

Quality Concerns of Doypacks

2 Pages

-

Material Testing

2 Pages

-

laboratory heat sealer

2 Pages

-

Automated Heat Sealer

1 Pages

-

analog thickness gauge

1 Pages

-

Residual Gas Analyzer

1 Pages

-

digital torque gauge

1 Pages

-

packaging Industry

2 Pages

-

Metrology and Test Equipment

2 Pages

-

Tensile Tester

2 Pages

-

material moisture monitor

2 Pages

-

Gas Analyzer

2 Pages

-

Headspace Gas Analyzer

1 Pages

-

FRICTION/PEEL TESTER

1 Pages

-

HOLDING TACK TESTER

1 Pages

-

ROLLING BALL TESTER

1 Pages

-

BOX COMPRESSION TESTER

1 Pages

-

INK RUB TESTER

1 Pages

-

FOGGING TESTER

2 Pages

-

Film Shrinkage Tester

1 Pages

-

Film Pendulum Impact Tester

1 Pages

-

FALLING DART IMPACT TESTER

1 Pages

-

THICKNESS TESTER

1 Pages

-

TOQUE TESTER

1 Pages

-

Tearing Tester

1 Pages

-

Gas Permeability Tester

1 Pages

-

Oxygen Permeability Tester

2 Pages

Archived catalogs

-

Leak Tester

2 Pages