Catalog excerpts

Labo-Net Advanced Touch Screen Control for Materials Handling Systems

Open the catalog to page 1

Labo-Net Introduction Labotek Labo-Net series takes full control of all materials handling requirements. A user-friendly interface via 10” touch screen provides automatic control of drying and/or conveying of raw materials. The Labo-Net system is supplied in wall mounted cabinet and enables great visual appearance of the features. Labo-Net is able to handle Labotek Energy Saving Systems & Labotek frequency controlled vacuum stations as standard. The Labo-Net uses network communication between system components via the well known, flexible and very reliable AS-Interface & Siemens Profi Net....

Open the catalog to page 2

LJ Power in Plastics fhannol 1-91 Labo-Net Scanning System V^l I CI I II I CM ± £_ J_ Power ill Plastics Pll—I / Msrhino Labe-Net Scanning System_L/l I / I IC3L.I III IC Material data: Line Clear time: | 5 Lowering temp. [ Temperature Log Char, overview Overview of Drying Hoppers Individual Drying Hopper data selection The Labo-Net is capable of controlling up to 40 Drying Hopper Stations (DH) and up to 3 Desiccant Flex Dryers (DFD). Desiccant air circulates the drying air in a closed system. The air is dried in desiccant beds where the dew-point temperature is lowered to -40°C or better....

Open the catalog to page 3

MA5CH1NEJ7 MA5CH1NE 38 Channel name Channel Name Channel Ma me Channel Name Channel Ma me Main Menu Back Line Clear time: | 20 Chan, ove^iew Graphic system overview Production machine Labo-Net may control up to 93 vacuum receivers and up to 5 vacuum stations. Suction time, line clearing time, suction address and air speed frequency is adjusted direct on screen, either via keyboard pad or drop down boxes. Vacuum station no is saved & selected per receiver, therefore one system could comprise as many receivers as the capacity of blower can safely manage. Labo-Net also features full control of...

Open the catalog to page 4

Technical Data The vacuum station set up menu is prepared for several central filter cleaning options, such as dust cyclone, self purifying filter or Blow Back Valve. Between cycles the individual stand by frequency may be selected leaving each vacuum station running at i.e. 10 Hz while waiting for next station to call for material. Full service menu with timers and complete alarm log Up to 3 Emptying stations for rapid purge of DH Product specifications Part No Description No of stations DH/SVR or Machine/SVR Max No of Drying Hopper stations DH & DFD Max No Vacuum Stations Vacuum station...

Open the catalog to page 5

Labotek A/S Strøbjergvej 29 DK-3600 Frederikssund +45 4821 8411 info@labotek.dk www.labotek.com Representative

Open the catalog to page 6All Labotek catalogs and technical brochures

-

Con-Evator SVR

6 Pages

-

Labotek EHR

2 Pages

-

EAC Drying System

2 Pages

-

Silos

6 Pages

-

Gravi-Dryer®

6 Pages

-

System Components

8 Pages

-

DDM

6 Pages

-

Gravi-Dryer

6 Pages

-

Magnet Grid

2 Pages

-

Labo-Scan

4 Pages

-

GraviMaster GM25

2 Pages

-

GraviMaster GM10

2 Pages

-

Gravimaster GM5

2 Pages

-

GraviMaster GM2

2 Pages

-

GraviMaster GM1,5

2 Pages

-

GraviMaster GM05

2 Pages

-

Ratio Selector IDV

6 Pages

-

Ratio-Selector 817/818

2 Pages

-

Ratio-Selector 2000

2 Pages

-

DFD-DH Series

8 Pages

-

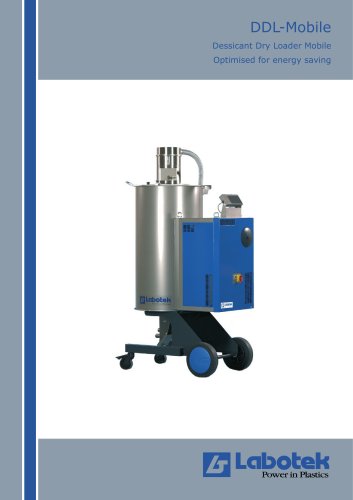

Desiccant Dry Loader, DDL

2 Pages

-

Desiccant Dryer Mobile , DDM

6 Pages

-

Con-Evator SVR

6 Pages

-

Mini-Feed 15-30-60

4 Pages

-

Conti-Crystallizer

2 Pages

-

Material Containers

2 Pages

-

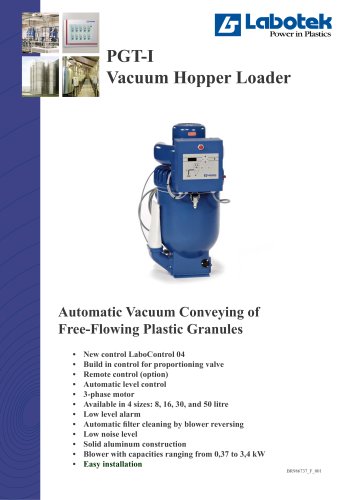

Con-Evator PGT

2 Pages

-

Mini-Feed 05

2 Pages