Catalog excerpts

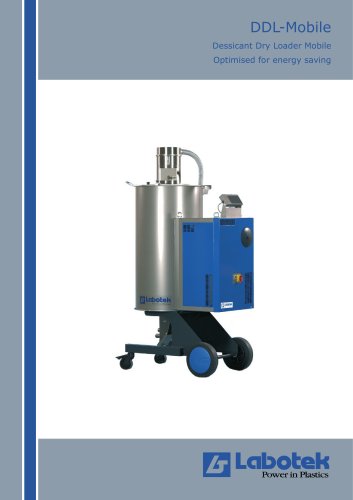

DDM SERIES Desiccant Dryer Mobile Drying of free-flowing granular plastic materials

Open the catalog to page 1

Desiccant Dryer Mobile - DDM Introduction Labotek’s series of mobile desiccant dryers, DDM, is designed for the continuous drying of free-flowing plastic raw materials in granulate form. The DDM is available as a complete desiccant drying and integrated dry air conveying system to processing machine, based on proven, reliable & energy saving design. The standard temperature range is 60 to 140ºC with a preset deviation of +/- 2ºC. A HT (High Temperature) model is also available with a temperature range of 60 to 180ºC. Owing to the extremely accurate temperature control and a dew point of...

Open the catalog to page 2

Drying The desiccant air blower (7) circulates the drying air in a closed system. The air is dried in one of the two desiccant beds (8) or (9), and the dew-point temperature is lowered to approx. -35°C. The dry air heating element (10) is used to heat the drying air to the required temperature before, via the air separator (6), it is distributed in the drying hopper DH (1). After the drying air has heated the raw material and transformed the moisture to water vapour, it is led back through the dust filter (11) to the blower (7). The humid air is cooled in the structural frame (12) of the...

Open the catalog to page 3

Technical Data DDM Type DDM 60 DDM 120 Supply Voltage DDM 180 3 x 50/60Hz 380-480V Installed Power, kW 8,6/9,0 9,0/9,3 9,0/9,5 1,1/1,4 1,5/1,9 1,5/1,9 Blower, drying Blower motor, drying - 3 Phase 50/60 Hz, kW Air volume m³/h - 50/60Hz 36/43 100/120 100/120 1400/1680 2400/2880 2400/2880 0,37/0,44 Water column [mm] 0,37/0,44 0,37/0,44 Blower, regeneration Blower motor, regeneration - 3 Phase 50/60 Hz, kW Dew point, temp. °C Better than -35°C Heating element, Drying - kW 2,5/2,5 3,5/3,5 3,5/3,5 Heating element, Drying HT version - kW 2,5/2,5 5,0/5,0 5,0/5,0 2x3,5/3,5 2x3,5/3,5 2x3,5/3,5...

Open the catalog to page 4

Capacity table for desiccant dryers Recommended dry time [h] Raw material Drying capacity kg/h at bulk density 0.6 Recommended drying temp. °C DDM 60 DDM 120 DDM 180 ABS Acrylonitrilebutadiene-styrene 2-3 80 18-12 36-24 54-36 PA Polyamide 6/6.6/10 3 75-80 12 24 36 PA Polyamide 11/12 4 75-80 9 18 27 PBTP Polybutylene therephtalate 3 120 12 24 36 PC Polycarbonate 2-3 120 18-12 36-24 54-36 PE Polyethylene 1-2 80-90 36-18 72-36 108-54 PE Polyethylene, black 3-4 90 12-9 24-18 36-27 PEC Polyestere carbonate 4-5 130 9-7 18-14 27-22 PEEK Polyaryletherketone 2-3 150 18-12 36-24 54-36 PEI...

Open the catalog to page 5

Labotek A/S Strøbjergvej 29 DK-3600 Frederikssund +45 4821 8411 info@labotek.dk www.labotek.com Representative

Open the catalog to page 6All Labotek catalogs and technical brochures

-

Con-Evator SVR

6 Pages

-

Labotek EHR

2 Pages

-

EAC Drying System

2 Pages

-

Silos

6 Pages

-

Gravi-Dryer®

6 Pages

-

System Components

8 Pages

-

DDM

6 Pages

-

Gravi-Dryer

6 Pages

-

Magnet Grid

2 Pages

-

Labo-Net

6 Pages

-

Labo-Scan

4 Pages

-

GraviMaster GM25

2 Pages

-

GraviMaster GM10

2 Pages

-

Gravimaster GM5

2 Pages

-

GraviMaster GM2

2 Pages

-

GraviMaster GM1,5

2 Pages

-

GraviMaster GM05

2 Pages

-

Ratio Selector IDV

6 Pages

-

Ratio-Selector 817/818

2 Pages

-

Ratio-Selector 2000

2 Pages

-

DFD-DH Series

8 Pages

-

Desiccant Dry Loader, DDL

2 Pages

-

Con-Evator SVR

6 Pages

-

Mini-Feed 15-30-60

4 Pages

-

Conti-Crystallizer

2 Pages

-

Material Containers

2 Pages

-

Con-Evator PGT

2 Pages

-

Mini-Feed 05

2 Pages