Catalog excerpts

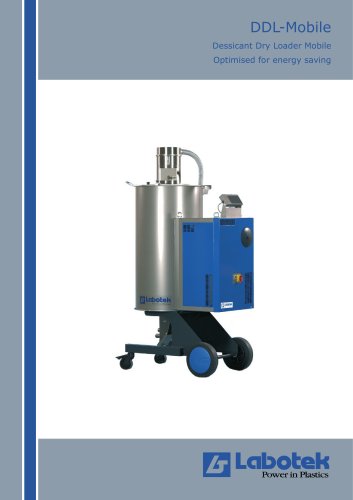

Desiccant Dryer Mobile Drying of free-flowing granular plastic materials

Open the catalog to page 1

Desiccant Dryer Mobile - DDM Introduction Labotek’s series of mobile desiccant dryers, DDM, is designed for the continuous drying of free-flowing plastic raw materials in granulate form. The DDM is available as a complete desiccant drying and integrated dry air conveying system to processing machine, based on proven, reliable & energy saving design. The standard temperature range is 60 to 140ºC with a preset deviation of +/- 2ºC. A HT (High Temperature) model is also available with a temperature range of 60 to 180ºC. Owing to the extremely accurate temperature control and a dew point of...

Open the catalog to page 2

Drying The desiccant air blower (7) circulates the drying air in a closed system. The air is dried in one of the two desiccant beds (8) or (9), and the dew-point temperature is lowered to approx. -35°C. The dry air heating element (10) is used to heat the drying air to the required temperature before, via the air separator (6), it is distributed in the drying hopper DH (1). After the drying air has heated the raw material and transformed the moisture to water vapour, it is led back through the dust filter (11) to the blower (7). The humid air is cooled in the structural frame (12) of the...

Open the catalog to page 3

Technical Data DDM Type Supply Voltage Blower, drying Blower motor, drying - 3 Phase 50/60 Hz, kW Air volume m³/h - 50/60Hz Blower, regeneration Blower motor, regeneration - 3 Phase 50/60 Hz, kW Dew point, temp. °C Heating element, Drying - kW Heating element, Drying HT version - kW Heating element, Regeneration - kW Cooling water requirement - HT version Max. pressure: 8 bar-flow 250 l/h-cooling water temp. In/out 15/40°C Drying Hopper, sizes (litre) Desiccant beds Return air hose, inner Ø [mm] / length [m] Conveying hose, inner Ø [mm] / length [m] Telescopic suction probe, Ø [mm] Net...

Open the catalog to page 4

Capacity table for desiccant dryers Recommended dry time [h] Drying capacity kg/h at bulk density 0.6 Recommended drying temp. °C Polybutylene therephtalate Polyethylene, black Polyestere carbonate Polyethylene terephthalate Polyethylene terephthalate glycol Thermoplastic polyestere Methylmethacrylate polymer Polyphenylene oxide Polyphenylene sulphide Polyethere sulfone Polyvinyl chloride Styrene acrylonitrile Styrene butadiene (high impact) Polyester elastomer Thermoplastic rubber The above capacity table states recommended values only, based on the drying of the specific materials down to...

Open the catalog to page 5

Labotek A/S Strøbjergvej 29 DK-3600 Frederikssund +45 4821 8411 info@labotek.dk www.labotek.com

Open the catalog to page 6All Labotek catalogs and technical brochures

-

Con-Evator SVR

6 Pages

-

Labotek EHR

2 Pages

-

EAC Drying System

2 Pages

-

Silos

6 Pages

-

Gravi-Dryer®

6 Pages

-

System Components

8 Pages

-

Gravi-Dryer

6 Pages

-

Magnet Grid

2 Pages

-

Labo-Net

6 Pages

-

Labo-Scan

4 Pages

-

GraviMaster GM25

2 Pages

-

GraviMaster GM10

2 Pages

-

Gravimaster GM5

2 Pages

-

GraviMaster GM2

2 Pages

-

GraviMaster GM1,5

2 Pages

-

GraviMaster GM05

2 Pages

-

Ratio Selector IDV

6 Pages

-

Ratio-Selector 817/818

2 Pages

-

Ratio-Selector 2000

2 Pages

-

DFD-DH Series

8 Pages

-

Desiccant Dry Loader, DDL

2 Pages

-

Desiccant Dryer Mobile , DDM

6 Pages

-

Con-Evator SVR

6 Pages

-

Mini-Feed 15-30-60

4 Pages

-

Conti-Crystallizer

2 Pages

-

Material Containers

2 Pages

-

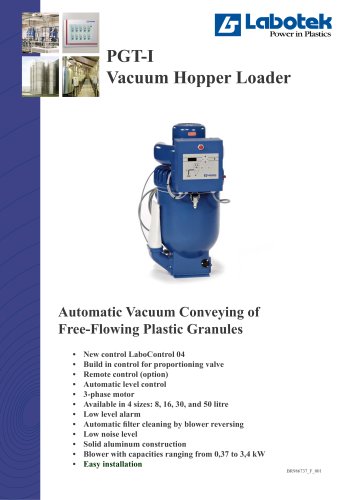

Con-Evator PGT

2 Pages

-

Mini-Feed 05

2 Pages