Catalog excerpts

Fitting the mold �KUKA Robots for the foundry and forging industry

Open the catalog to page 1

Optimally equipped for harsh working environments KUKA solutions for the foundry and forging industry The foundry and forging industry gives a new face to many raw m aterials. KUKA robots help here, with a wide range of highly e fficient automation processes, installed on, in or next to the m achine. From sand mold production, casting and forging to surface finishing, they increase the quality and efficiency of manufacturing processes and protect your employees against hazardous production influences such as heat, dust or gases. Fitting the mold�KUKA Robots for the foundry and forging...

Open the catalog to page 2

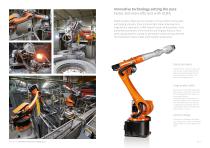

Innovative technology setting the pace Faster and more efficient with KUKA KUKA Foundry robots are all-rounders in the world of the foundry and forging industry. From intricate light alloy components to large-format steel parts: KUKA robots master all disciplines in the automated processes of the foundry and forging industry, from sand casting and die casting to permanent mold casting and even the handling of heavy molds and finished components. Optimized robots With their heat-, corrosion-, alkali- and acid-resistant coating, KUKA Foundry robots are optimally equipped for the harsh working...

Open the catalog to page 3

The QUANTEC F series The strongest in their payload category The QUANTEC K-F series Shelf-mounted robots with superior dynamism Metal – red-hot, molten or solid. From intricate light alloy components to large-format steel parts: the KR QUANTEC F series masters all d isciplines from sand casting and die casting to permanent mold casting and even the handling of heavy molds and finished components. It effortessly handles payloads of up to 300 kg. The extremely robust and l maintenance- riendly design makes it a sound investment for the future. f The KR QUANTEC K-F series offers the right...

Open the catalog to page 4

KUKA smartPAD and KR C4 The perfect duo for optimal robot operation Complex systems. Simple operation. The KUKA smartPAD and the KR C4 are the ideal symbiosis for users. They enable intuitive and efficient control of even challenging tasks. The KUKA smartPAD can be deployed universally and is easy to handle with its large touch display. The KR C4 unites all relevant control tasks for the efficient use of robots in a single system – with maximum energy efficiency. KUKA smartPAD – m aking light work of complex tasks Master even complex operating tasks easily – that’s what the KUKA smartPAD is...

Open the catalog to page 5

KUKA robot range The right solution for every task KR AGILUS series The KR AGILUS series with unparalleled performance at the highest of speeds is also available as a waterproof variant with protection rating IP 67. KR CYBERTECH F series High process reliability. Economical. Robust. Even in the demanding environments of the foundry and forging industry, our robots offer consistently high performance – with particularly low follow-up costs. KR CYBERTECH KS F series This series is ideally suited to space- saving cell concepts and provides top performance. It is optimally designed for working...

Open the catalog to page 6

www.kuka.com/contacts www.facebook.com/KUKA.Robotics www.youtube.com/kukarobotgroup Specifications regarding the characteristics and usability of the products do not constitute a warranty of properties. They are intended to serve informative purposes only. Solely the respective contract of sale shall be binding in respect of the extent of our services and supplies. Some items of equipment depicted in the illustrations are optional and are not included in the standard scope of supply. Technical Data and illustrations are not binding for the delivery. Subject to change without prior notice. ©...

Open the catalog to page 7All KUKA AG catalogs and technical brochures

-

KR 120 R3200 PA-HO

1 Pages

-

KR 3 D1200 HM

2 Pages

-

KMP 600

2 Pages

-

KUKA KR IONTEC

2 Pages

-

KR CYBERTECH nano

2 Pages

-

KUKA KMP 1500

5 Pages

-

KUKA Genius-Family

4 Pages

-

KUKA Genius V

2 Pages

-

KUKA Genius D

2 Pages

-

KUKA Genius

2 Pages

-

KUKA LBR iisy

13 Pages

-

KUKA Robotics_Range

4 Pages

-

KUKA smartPAD

2 Pages

-

KUKA used robots

4 Pages

-

KUKA KR QUANTEC Foundry

2 Pages

-

KUKA KR 4 AGILUS

2 Pages

-

KUKA robot controller KR C5

2 Pages

-

KUKA_KR_C5_micro

2 Pages

-

KUKA mobile training cell

2 Pages

-

PF0056_KR_5_scara

2 Pages

-

Automation for machine tools

11 Pages

-

KUKA KMR iiwa

5 Pages

-

KUKA Coaster

3 Pages

-

KUKA robots for high payload

22 Pages

-

KUKA KR C4

14 Pages

-

KUKA KR Cybertech

11 Pages

-

KUKA ready2_spray

2 Pages

-

KUKA ready2_pilot

2 Pages

-

KUKA Robotics Robot Range

4 Pages

-

KUKA LBR iiwa

18 Pages

-

Technology Development

3 Pages

-

KUKA energy supply systems

35 Pages

-

Productbrochure LOW PAYLOAD

25 Pages

-

KUKA MachinetoolsAutomation

11 Pages

-

KUKA robots for arc welding

11 Pages

-

LBR iiwa Med

4 Pages

-

KUKA refurbished robots

4 Pages

-

KUKA omniMove

4 Pages

-

KR 700 R2510 passenger

4 Pages

-

KUKA omniMove tripleLift

5 Pages

-

KUKA ready2_use

8 Pages

-

KMR QUANTEC

5 Pages

-

LBR iiwa 7 R800 RAL 9016

17 Pages

-

KR 240 R3200 PA arctic

2 Pages

-

KR 500 R2830

2 Pages

-

KR 6 R700 sixx C-WP

2 Pages

-

KUKA Navigation Solution

4 Pages

-

KUKA Industrie 4.0

34 Pages

-

KUKA Sunrise Cabinet

2 Pages

-

KR QUANTEC PA arctic

2 Pages

-

KR AGILUS Waterproof

2 Pages

-

Global. Cuetomer. Services

18 Pages

Archived catalogs

-

KUKA Palletizing Robots

63 Pages

-

Cleanroom robots

12 Pages

-

Compact robots

6 Pages

-

KUKA Arc welding

14 Pages

-

KUKA KR 1000 titan

6 Pages

-

KUKA Customer Services

12 Pages

-

Robot Range

2 Pages