Catalog excerpts

Engineering Value KraussMaffei

Open the catalog to page 1

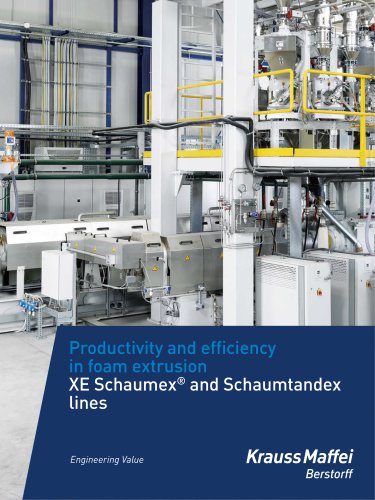

XE Schaumex® and Schaumtandex lines Applications Practical examples High-quality products for the most varied industries Pressure and moisture resistant insulation boards Food packagings made of expanded polystyrene Tube insulation for heating and sanitary applications Expanded film for the packaging and building industries Decorative profiles XPS boards for external insulation of basement walls PET foam as core material for rotor blades Insulated heating tubes

Open the catalog to page 2

Foam extrusion lines Unparalleled product quality and reliability KraussMaffei Berstorff provides reliable highperformance machines and lines along the entire value-adding chain in the production of physically foamed plastics film, sheets, pipes, profiles and boards. The machinery meets all requirements for an efficient extrusion process. Benefits at a glance: – utput rates of up to 2,000 kg/h in the production O of XPS boards – road processing range covering all standard B plastics (PS, PE or PP) and many hightemperature plastics (PET, PEI and PES) up to a maximum temperature of 350°C – se...

Open the catalog to page 3

Impressive encounter: Take a closer look at a complete extrusion line for the production of expanded film or tubes Twin-screw extruder Single-screw extruder melt cooling Blown film die for the flexible production of film in different Expanded film calibrator

Open the catalog to page 4

The layout shows the complete ZE60/KE150 Schaumtandex line comprising: 10 Gravimetric metering system with suction conveyor 20 ZE60Ax30D-UTX twin-screw extruder 25 KE150x30D single-screw extruder 30 Temperature control units (oil and water) 40 Blowing agent metering pump 50 Electrical control system 60 Blown film die with air cooling ring 70 Calibrator 80 S-wrap 90 Automatic double turret winder 100 Double tube die 110 Cooling unit 120 Take-off and cutting unit 130

Open the catalog to page 5

ISO-PAC and ISO-TUBE Schaumtandex lines Expanded film and sheets Excellent film quality, unparalleled output rates and high technical reliability KraussMaffei Berstorff Schaumex® and Schaumtandex lines combine matured process expertise with pioneering technologies to innovative extrusion concepts. There is a wide field of applications for foamed film and sheets – starting from cap seals and boxes up to rear parcel shelves. Our extrusion lines are designed for light and heavy foam sheets made of PS, PE, PP, PET and PLA. Thanks to the extremely precise temperature control, these lines ensure...

Open the catalog to page 6

Tube and profile production lines Perfect symbiosis of innovation and tradition ISO-TUBE Schaumex® and Schaumtandex lines meet the most exacting standards in terms of quality, productivity and reliability in the production of PE, PP and PE/EVA foam tubes or profiles. This applies to the following machine configurations: – Schaumex® line with single-screw extruder for low output rates, – E/KE Schaumtandex line with two K single-screw extruders for medium output rates, – E/KE Schaumtandex line composed Z of a twin-screw extruder and a singlescrew extruder for maximum throughput rates....

Open the catalog to page 7

Impressive encounter: Take a closer look at a complete board extrusion line Single-screw extruder for efficient and reliable melt cooling Twin-screw extruder of modular design Operator panel for maximum ease of operation Plate calibrator for different product thicknesses and surfaces

Open the catalog to page 8

The layout shows a ZE90/KE250 Schaumtandex line for an output rate of 800 kg/h composed of the following components: 10 Gravimetric metering system with suction conveyor 60 Slot die 20 ZE75 x 30D extruder 70 Plate calibrator 25 KE250 x30D extruder 80 Roller take-off unit 28 Static mixer 100 Board milling and stacking unit 30 Temperature control units (oil and water) 110 Packaging system 4-0 Blowing agent metering unit 120 Suction system with silo 50 Electrical control system 130 Granulator

Open the catalog to page 9

ISO-Board Schaumtandex lines Added value through premium technology ISO-BOARD Schaumtandex lines Premium technology provides substantial added value ISO-Board Schaumtandex lines are the world’s most successful systems for manufacturing XPS heat insulation boards. Amazing? Not really! KraussMaffei Berstorff is well familiar with the challenging requirements that a Schaumtandex line must fulfill to create added value – both today and in the future! ISO-BOARD Schaumtandex lines are the leading technology to enhance productivity and cost effectiveness in the production of XPS boards. In...

Open the catalog to page 10

ZE/KE Schaumtandex lines The direct way to success – Profitable symbiosis of flexibility and performance Innovative productivity enhancement based on a wellproven line concept – ZE/KE Schaumtandex lines combine the groundbreaking ZE twinscrew extruder technology with the efficient cooling properties of the KE single-screw extruder. Throughput rates of up to 2,000 kg/h and the suitability for a wide range of different raw materials give enhanced productivity and uncompromising cost effectiveness. Versatile, highly productive and all-around profitable – the ZE/KE Schaumtandex sets new...

Open the catalog to page 11

Schaumtandex KE/KE The cost-effective solution KE/KE Schaumtandex lines The cost-effective solution for output rates of up to 800 kg/h The KE/KE Schaumtandex line is the all-rounder for a wide variety of applications in physical foaming of plastics. It stands for high production reliability and maximum ease of operation at medium output rates of up to 800 kg/h. The advanced technology is suited for processing a broad spectrum of standard plastics. Due to its special screw design, the single-screw extruder for plastics melting and mixing, which is unique in its class, provides for optimum...

Open the catalog to page 12

Schaumex® lines Maximum productivity combined with minimum space requirements Schaumex® lines are the ideal solution for the production of high-quality foam products at output rates of up to 320 kg/h. The complete foaming process is performed in a single extruder – from polymer melting, blowing agent injection and incorporation up to melt cooling. Thanks to the compact design, the line needs only little space to develop its full potential. In addition, the high degree of automation ensures maximum ease of operation. Your benefits: – High degree of automation – Throughput rates of up to 320...

Open the catalog to page 13All KraussMaffei catalogs and technical brochures

-

Film and sheet extrusion lines

24 Pages

-

Complete system solutions

16 Pages

-

ZE twin-screw extruders

30 Pages

-

Hose extrusion lines

16 Pages

-

Multiplex Extrusion Lines

16 Pages

-

AHEAD 2014

28 Pages

-

Pipeheads for polyolefins

14 Pages

Archived catalogs

-

MX injection molding machines

20 Pages

-

Machines in the GX Series

26 Pages